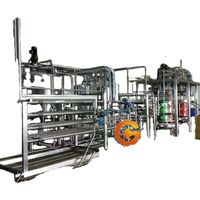

Steam Heating Autoclave For Canned Food Industry

-

Supplier: Zhucheng Zhonggong Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Alice guo -

Price: $7850.00 /set -

Min. Order: 1 set

| Voltage: | 220V/380V; | function: | sterilization; |

| Sterilizing Type: | Setam; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Model Number: | different; | Applicable Industries: | Hotels,Food & Beverage Factory,Restaurant,Food Shop,Food & Beverage Shops; |

| Feature: | Cost Effective; | Design Temperature: | 147 Degree Centigrade; |

| Quality: | High Standard; | Condition: | New; |

| Heating way: | Boiler Steam Heating; | Brand Name: | ZONGON; |

| Weight: | 3000kg; | Certification: | CE; |

| Dimension(L*W*H): | 4500mm x 2300mm x 2900mm; | Color: | Silver; |

| After-sales Service Provided: | Online support; | Material: | 304 Stainless Steel; |

| Place of Origin: | Shandong China; | Supply Ability: | 18 Set/Sets per Month; |

| Warranty: | 1 Year; | Model: | ZONGON; |

| Power(W): | 36KW; | Packaging Detail: | Standard packing Steam Heating Autoclave For Canned Food Industry; |

| Port: | QINGDAO; |

Steam Heating Autoclave For Canned Food Industry

Steam Heating Autoclave For Canned Food Industry The water immersion type sterilizing retort heats the water of the hot water tank to a predetermined temperature by directly injecting steam, and then injects into the process tank, and continuously circulates the process water in the pot, and sterilizes by circulating steam heating. Thereby shortening the sterilization time and improving work efficiency. The sterilized process water can be recycled, saving energy, time and manpower, material consumption, and reducing production costs.

1. Uniform temperature distribution:In the process of heating and sterilization, the water is continuously sprayed from nozzles adopted high speed spraying, so that the temperature in the pot is kept stable and the sterilization effect is improved.

2. Direct heating and indirect cooling, and prevent the second pollution. Sterilizing and cooling processes use the same water. Circulating water is directly heated by steam diffusion tube in the heating process. Under 0.5MPapressure, it only takes 6-12min to rise the temperature from 20 DEG to 121 DEG. Continuous cooling by heating exchanger is isolated from the products, preventing the second pollution in the cooling effectively.

3. Full-automatic control system:

a. Siemens Touch Screen

b. No-paper recorder

c. Imported Automatic Valves

1.For high temperature sterilization of fruits, vegetables, meat, fish, convenience foods, etc.

2.Scientific experiments show that the best sterilization temperature of the tide type brine food is 121 DEG, the best sterilization time is 12min, which can not only ensure the good sterilization effect, but also keep the flavor of the brine.

3.Mainly applicable to canned food (such as meat, fish, eggs, vegetables etc.), protein beverage (milk, soy milk, coconut milk, peanut milk, walnut milk, almond milk etc.), hard cans (tin cans, glass bottles, cans etc.) and various kinds of soft packaged food.

Exporting package , per your requirements

Before delivery, our professional technician will do trial run for each product to check until everything is functional, you also can come to our factory and test our machine together with us.

When loading, our workers will fix the retorts tightly with wire rope so that the retorts can't move in the container.

Our company was established in 2002, and we are committed to engaging in food fully automatic new atmosphere retorts, automatic universal cooking pot, new gas modulation nitrogen machine, new modified atmosphere packaging machines, new modified atmosphere food technology, conventional high-temperature sterilization pot sandwich pot research, design, manufacturing, modern services in one company, and our company has a national pressure vessel manufacturing license qualification(Certificate Number: TS2237350-2013), and successfully passed the food safety regulator's Shandong Province, the KYL type retorts Open the door security chain device identification(ID: SY-WT-2010-0019), and the products have passed the ISO9001 international management system certification, and our company has independent import and export operation rights.

WE ALWAYS EXPLOR ALL THE POSSIBILITIES TO HELP CUSTOMERS TO SOLVE PROBLEMS AND UPGRADE THEIR PRODUCTS QUALITY.

1. What if there is something wrong with the machine within one and half year?

We have two ways to solve this problem:

2.Phone call guidance to confirm the problem.

3. We will take video to show 'how to solve the problem'. All the problem can be solved by video guidance.

4.What if the PLC is suddenly broken down?

We use German Brand PLC, it is quite stable brand. If really broken down, what we usually do is:

1) We suggest customer to buy one more for storage. The computer we will also upload the

program.

2) Once it is broken down, then take replace the new one, the broken one, send back to us, we re-do the system, and send it back to you again.

5.What is the difference between retort and autoclaving?

Both words refer to the process of sterilizing a given item. This item could be medical instruments, a sealed container of food, or anything else.So there is no difference between these two terms. They are two different ways to say the same thing.

6.Is retort machine advisable to replace autoclave in microbiology laboratory?

A retort is an autoclave. The difference here is that our retorts can perform various processes i.e. water spray, water immersion and steam-air in addition to saturated steam with or without horizontal or rotational agitation.

-

Small ultra-high temperature sterilized milk processing plant milk tray type ultra-high temperature sterilizer

-

Food processing water spray sterilizer pot sterilizer machine made in China

-

Mini Cooker Autoclave Mini Cooker

-

Edible fungus sterilization sterilizing pot sterilizing pot / shiitake mushroom sterilizing pot high-pressure sterilizer

-

food cooking

-

Hot-selling food mushroom sterilization equipment

-

35L 50L 75L 100L 120L 150L Vertical Pressure Steam Sterilizer Autoclave on Hand Wheels

-

Cooking Autoclave Food Sterilization Equipment Small Back Pressure Sterilizer

-

Sterilizer

-

cooking machine