High speed ceramic bearing 6000 6201 6202 6203 6204 6205 6301 6302 6303 2rs

-

Supplier: Jinan Shenglei Bearing Co., Ltd. -

Region: Shandong, China -

Contact: Mr leon Han -

Price: $2.00 /set -

Min. Order: 1 set

| Special bearing: | High temperature bearing; | Material of balls: | Ceramic Material Zro2/si3n4; |

| Brand Name: | ZYSL; | Number of Row: | Single Row; |

| Supply Ability: | 100000 Set/Sets per Month ceramic bearing 6202; | Lubrication: | Oil-free Self-lubricating; |

| Place of Origin: | Shandong China; | Vibration Level code: | V1,V2.V3; |

| Payment Terms: | T/T,Western Union,T/T Western Union Paypal; | Package: | Single box packing; |

| Seals Type: | Open 2RS ZZ; | Packaging Detail: | 1.plastic bag+kraft paper+carton+plywood pallets 2.plastic tube+carton+plywood pallets 3.plastic bag+color box+carton+plywood pallets 4.as the client's requirment; |

| Cage: | Nylon PTFE UPE PA; | Material: | Si3N4,ZrO2,Sic; |

| Type: | Ceramic Ball; | Application: | Food Machinery; |

| Model Number: | 6202; | Port: | shen zhen; |

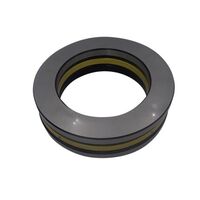

High speed ceramic bearing 6000 6201 6202 6203 6204 6205 6301 6302 6303 2rs

ZYSL is a specialized manufacturer of Ceramic Bearing. Full Complement ceramic bearings,Ceramic Balls.

Hybrid Ceramic Bearing:

Ceramic bearings offer a significant performance improvement from those made from traditional steel. Our ceramic bearings are manufactured from silicon nitride (Si3N4), an exceptionally hard non-metallic material rated for speeds to 2 million dN, offering a wide selection of benefits.

Hybrid Bearings have steel rings and ceramic balls. Si3N4 Ball is the most popular for the balls as it has only 40 percent of the density of bearing steel but is much harder giving greater wear resistance. Zirconia is heavier with 75 percent of the density of steel so is less suitable for hybrid bearings..

Full Ceramic Bearing:

Full Ceramic Bearings are made entirely of ceramic material and are superior to common steel bearings in many ways. Ceramic is the perfect material for any application seeking to achieve higher RPM’s, reduce overall weight or for extremely harsh environments where high temperatures and corrosive substances are present. Applications such as cryopumps, medical devices, semiconductors, machine tools, turbine flow meters, food processing equipment, robotics and optics. Ceramic materials commonly used for bearings are Silicon Nitride (Si3N4), Zirconia Oxide (ZrO2), or Silicon Carbide (SiC.)

Ceramic Balls:

We are special in making Silicone Nitride Balls (Si3N4 Balls,Zicronia Balls (ZrO2 Balls),Sic Ceramic Balls , Aluminum Oxside Valve (AI203) ceramic balls.

Compared with steel, ceramic materials are noted for their better or particular characters, such as wear-resistance, corrosion resistance, high temperature resistance, electrical insulation (except SiC), non-magnetic, high strength, high rigidity, and low specific gravity. These properties qualify them for replacing steel to make bearings serve in conditions of higher speed, harsh environment and less lube, and decrease wear, noise, vibration and maintenance time of bearings, and eventually increase performance, reliability and life of bearings.

Cearmic Bearings can be Category by Configuration as follows,

The same size can be made of different materials, including

Stainless Steel Bearings

Chrome Steel Bearings

Carbon Steel Bearings

High speed ceramic bearing 6000 6201 6202 6203 6204 6205 6301 6302 6303 2rs

| Name | high speed ceramic bearing |

| Seals Type | OPEN/ZZ/2RS |

| Material | ZrO2,Si3N4 |

| Cage material | Ceramic,PTFE,Nylon,Steel |

| Clearance | C0,C2,C3,C4,C5 |

| Vibration | Zv1,Zv2,Zv3 |

| Precision | P0,P6,P5,P4 |

| Greese | Lithium soap base grease or as customer's requirement |

| Application | Home appliances, low noise and high speed electric motors,automotive components, pumps, machinery. |

| Certifications | ISO9001 quality management system |

| Package | 1) Single box + outer carton + pallets 2) Tube package + outer carton + pallets 3) According to customer request |

| Service | 1) OEM 2) After-Sales Service 3) 24 hours service |

| Payment Term | 1) T/T : 30% deposit , 70% before shippment. 2) L/C at sight. (high bank charge, not suggest , but acceptable ) 3)100% Western Union in advance. (specially for air shipment or small amount) 4) Paypal |

| Port | Qingdao, Guangzhou, Shanghai port |

The Advantage of products

1.High precision bearings,P4 ,P5 and P6.

2.Rings are made of refined Chrome steel.stainless steel 440C

3.Cage:Peek & PTFE cage .(can assure constant working under 250 centigrade)and peek cage also is the ideal cage for the high speed as it can provide the lubrication during bearing working, and it has the property of self-lubrications.However for normal applications, steel cage and Nylon cage is enough.

4. Balls: we use G3,G5 high precision Si3N4 ball for the high speed.

5. Radial clearance: Normal C0,or C3.

6.Not only for the high speed, but also Hybrid bearings has the

insulation functions. Hence for the small size of bore dia.40mm ,

also can be used for the insulation bearing purpose.

7.Full ball hybrid also can be produce as per our production picture.

All-ceramic bearings have good to excellent corrosion resistance, are non-magnetic and, apart from silicon carbide, are electrically insulating. All-ceramic bearings can be used in high to very high temperatures if supplied without a cage (full complement).

Electrical resistance: Si3N4 best, then ZrO2, then SIC which is conductive.High temp resistance:

SiC best (1100C), then Si3N4 (1000C), then ZrO2 (400C) Corrosion resistance:

SIC (excellent), then Si3N4 (very good) and ZrO2 (good)Load capacity:

SIC highest then Si3N4, then ZrO2 Fracture toughness:

ZrO2 best, then Si3N4, then SiC

All-ceramic bearings have lower load and speed ratings than steel or hybrid bearings. The speeds are lower due to the lower precision and roundness of the rings and the loads are lower because the material is more brittle. Under heavy loads and particularly heavy shock loads, there is a risk of cracking. For the same reason, great care should be taken with interference fits. Zirconia is the least brittle so it will handle shock loads and very small interference fits better than the other ceramic materials with silicon carbide being the most brittle. Shock loads should be avoided with all-ceramic bearings. Great care should be taken when using ceramic bearings (especially silicon nitride and silicon carbide) on steel shafts at high temperature due to the difference in expansion coefficient and the relative brittleness of ceramics.

Product show

Application

Package

Jinan ZYSL bearing Co., Ltd.are manufacturer and supplier from Jinan Shandong China , Which is on the line of bearing for more than 20 years experience .We integrate R&D,production and export of bearings.

So one of our biggest advantage compared others is that we can provide the best factory price based on the same good quality.Our employees are all received professional training.

And until now we has established a professional sales network to help customers get products information at the first time.Besides our company has strong technical strength, excellent processing equipment and complete testing equipment to ensure quality of bearings.The annual production capability is more than 960 million units.Quality is our culture and credibility is our primary principle in our business. So we constantly strive for research and innovation development, adhere to the concept of "survival of high quality", and provide excellent service for customers.

Small orders:

A:100% T/T

B:Western Union

C:Paypal

Large orders:

D:30% T/T in advance, 70% against copy of B/L

MOQ IS ONE PIECE

TERMS OF PAYMEMT: T/T

SAMPLE AVAILABLE

PACKING: CARTON OR WOODEN BOX OR ACCORING TO CUSTOMER REQUIREMENT

SHIPMENT: Logistics forwarder or Express service, according to quantity

Delivery time: 3-15 days according to quantity required

Quality: Export standard

Price term: FOB

1. How long is your delivery term?

Our standard product delivery term is normally 30 days. A new product development cycle is 60 days in normal. Under normal circumstances, there are standing stock for regular types. You can email us to learn more details.

2. Where is your port of shipment located?

Our main port of shipment is Guangzhou port, and we may operate at other ports if required by the customer.

3. I couldn’t find a design to fit my application in your catalog. Can you help me design a bearing?

Yes, technical expertise is available to assist you with engineering design for custom products. Available options include, but are not limited to, custom rings, retainers, balls, shields, lubricants, and packaging. We look forward to working with you to satisfy your rotary motion requirements.

Skype:cindy.chen125

whatsapp:+8615098917851

I am looking forward to receiving your enquires soon .^ - ^

-

Fishing Reel Bearing 3x6x2.5mm Full Ceramic Bearing

-

motorcycle ball bearing 6004 6201 6202 6203 6300 6301 RS

-

High quality white Si3N4 uc203 uc204 uc205 uc206 ceramic insert bearing

-

High grade ball bearings abec9 zirconia zro2 si3n4 micro-ceramic 3x10x4 r8 r144 6204 608 full ceramic bearing

-

Cheap Bearings High Speed Ceramic Ball Bearings 12 32 10mm 6201 Bearings

-

BARDEN C34-5SSTY63 for TURBOVAC TW70 turbomolecular pump

-

New products 2018 NSK 608 ceramic ball bearings made in China

-

608 cageless ceramic bearing 608 full-fill ceramic high temperature resistant 1000 German 608 hybrid ceramic ball bearing without cage

-

Motor Ceramic Bearings SR2C-ZZ RC ZZ 3,175mm x 9,525mm x 3,967mm

-

Full Zirconia Ceramic Bearings 608z 6000 6001 6002 6003 6004 6005 High Speed Static Nylon Bearings Small Bearings

Other Products

-

$182.00 / piece

$182.00 / piece -

$22.10 / set

$22.10 / set -

$15.00 - $15.17 / set

$15.00 - $15.17 / set -

$10.72 / piece

$10.72 / piece -

$2.00 / set

$2.00 / set -

$3.72 / set

$3.72 / set -

$31.25 / set

$31.25 / set -

$1.60 / piece

$1.60 / piece -

$0.05 / set

$0.05 / set -

$3.00 / piece

$3.00 / piece