Big Capacity Jelly Oil Cable Wire Granulator

-

Supplier: Zhengzhou Zhengyang Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Jack Hao -

Price: $12500.00 /set -

Min. Order: 1 set

Product details

| Condition: | New; | Working methid: | machinery; |

| Weight (KG): | 1790; | Color: | Requirement; |

| Power (kW): | 45; | Brand Name: | SUNY; |

| Capacity: | 100-2000kg/h; | Warranty: | 1 Year; |

| Port: | Qingdao; | Service life: | 8-10 Years; |

| Applicable Industries: | Manufacturing Plant; | Name: | Big Capacity Cable Wire Granulator; |

| Warranty: | 1 Year; | Place of Origin: | China; |

| Payment Terms: | T/T,Western Union; | Packaging Detail: | 20 or 40 lift container; |

| Fuel: | Electric Power; | Application: | Solid Waste; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Key Selling Points: | High copper separation rate; |

| Supply Ability: | 20 Set/Sets per Month Big Capacity Cable Wire Granulator; | Certification: | CE ISO; |

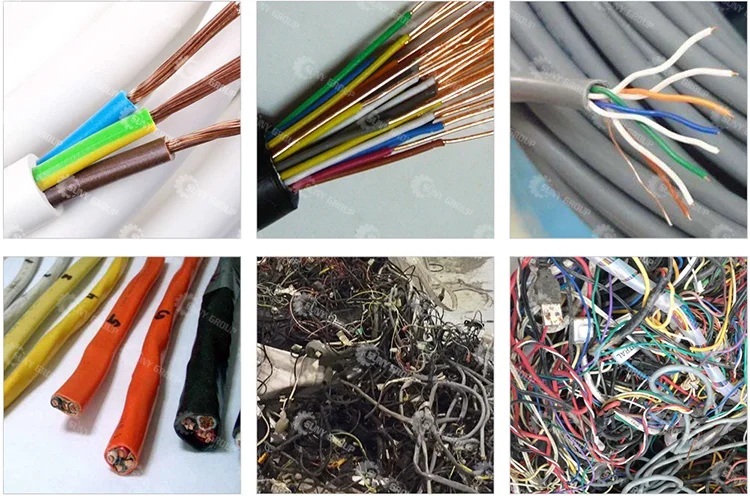

| Raw material: | all kinds of cables scrap,car wire,home used cables,earphone cables; |

Big Capacity Jelly Oil Cable Wire Granulator

PRODUCT DISPLAY

TECHNICAL PARAMETERS

| Model | Power (Kw) | Weight (Kg) | Capacity (Kg/H) | Dimension (m) |

| ZY-TMJ200 | 28 | 1850 | 100-200 | 2.2*2*2.3 |

| ZY-TMJ300 | 39 | 2500 | 200-300 | 3.2*2.1*2.3 |

| ZY-TMJ400 | 45 | 3200 | 300-400 | 4*2.1*2.5 |

| ZY-TMJ500 | 68 | 3850 | 400-500 | 6.2*5*3.3 |

| ZY-TMJ800 | 75 | 5500 | 700-800 | 10.4*2.1*3.3 |

| ZY-TMJ1000 | 95 | 8200 | 800-1000 | 12*4.1*4.5 |

1. Working voltage:380±10V(415V ,440V also can be custom);

2. It can be customized fur 1t/h ur larger capacity.

(If you want more detailed parameters and quotations, please contact us)

VIEW MORE

You may like

-

2023 Vaner Small Wire Shredding Cable Copper Granulator Cable Wire Recycling Machine

-

50-80kg/hour mini copper granulator waste copper wire recycling machine

-

Mini Copper Granulator Copper Wire Shredder Cable Recycling Machine Scrap Metal Recycling Equipment

-

Aluminum Plastic Separator ACP Panel Plate Heating Separator

-

Copper cathode manufacturing equipment Copper electrolysis equipment

-

Dujiang Waste Plastic Products Recycling Plastic Bucket Crusher Double Shaft Shredder

-

Household cheap scrap copper wire granulator wire copper recycling machine 50KG/H waste cable copper recycling machine

-

50-80 kg/h mini copper granulator scrap copper cable granulator per kg pure copper recycling machine

-

2022 BSGH high-efficiency cable wire granulator and high separation rate copper recycling equipment BS-F1000

-

High quality control cable voltage power cable copper wire stripping machine

Other Products

-

$5000.00 / set

$5000.00 / set -

$12000.00 / set

$12000.00 / set -

$5000.00 / set

$5000.00 / set -

honeycomb coal briquette punching machine , Charcoal briquette pressing machine for making briquette$2000.00 / set

honeycomb coal briquette punching machine , Charcoal briquette pressing machine for making briquette$2000.00 / set -

$20000.00 / set

$20000.00 / set -

$700.00 / set

$700.00 / set -

$50000.00 / set

$50000.00 / set -

$40000.00 / set

$40000.00 / set -

$30000.00 / set

$30000.00 / set -

$5000.00 / set

$5000.00 / set