floating fish food pellet processing making extruder price fish feed machine

-

Supplier: Jinan Dingrun Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Linda Tang -

Price: $6000.00 /set -

Min. Order: 1 set

| Brand Name: | dingrun; | package: | wooden cases; |

| type: | twin screw extruder; | Warranty: | 1 Year; |

| Port: | Qingdao Port; | After-sales Service Provided: | Field installation, commissioning and training; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Application: | Fish; |

| Voltage: | 380V/50HZ; | Product name: | floating fish food machine fish feed machine; |

| Applicable Industries: | Manufacturing Plant,Farms,Retail; | Supply Ability: | 20 Set/Sets per Month floating fish food machine fish feed machine; |

| Whatsapp/wechat: | +86 15020006735; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,for Floating fish feed extruder machine; |

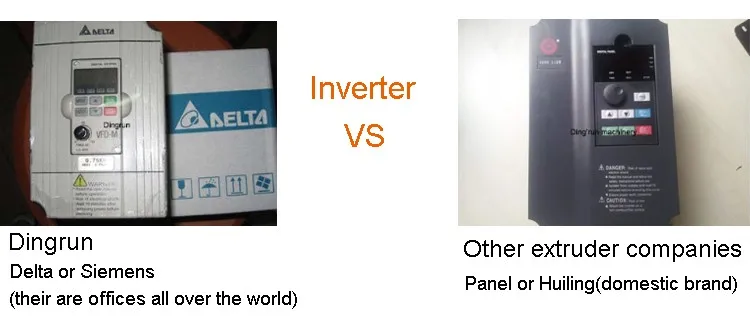

| screw diameter: | 65mm to 100mm; | main motor brand: | ABB or simens; |

| material: | SS304; | Weight: | 1500kg; |

| Dimension(L*W*H): | 25000*1500*2200; | Power(W): | Entire Line; |

| application: | fish /cat/ dog /bird; | Certification: | CE; |

| Condition: | New; | Packaging Detail: | floating fish food machine fish feed machine 1. Inside package is plastic film, outside is wooden or plywood case (based on the customers' need for Floating fish feed extruder machine). 2. Only plastic film nude packing with wooden pallet. 3. We can supply fumigation package and certificate. 4. Shipping, train, express or upon clients' demands.; |

| Place of Origin: | Shandong China; | keywords: | fish feed extruder machine; |

Single screw extruder

US $ 2000-3500

twin screw extruder

US $ 8000-10000

Top Sale Simense ABB or Chinese Brand Shrimp feed machine

1). All fish food equipments are made of stainless steel.

2). The fish food whole line fully continuous and automatic.

3). Dingrun provide basic fish food formula according to your require.

4). The final fish food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the fish feed production line (depending on your require)

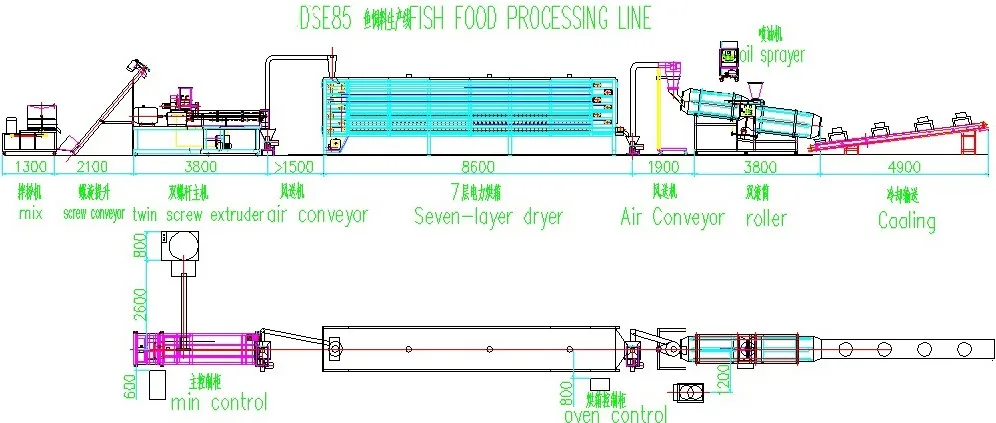

Flow chart diagram:

Technical parameter for fish feed extruder

Raw material:

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

Final product:

fish feed pellet /color customized/floating and sinking type/length customized

diameter from 0.2mm to 20mm

Equipment list in the fish feed production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

1)mixer of fish feed machine floating fish feed pellet machine

2)extruder of fish feed machine floating fish feed pellet machine

Dry type twin screw extruder for fish feed

capacity from 100kg/h to 1 ton/h

Wet type twin screw extruder for fish feed

capacity from 200kg/h to 10 ton/h

3)oven of fish feed machine floating fish feed pellet machine

Electrical heating dryer

Gas or Diesel fired heating dryer

4)flavoring of fish feed machine floating fish feed pellet machine

5)packaging of fish feed machine floating fish feed pellet machine

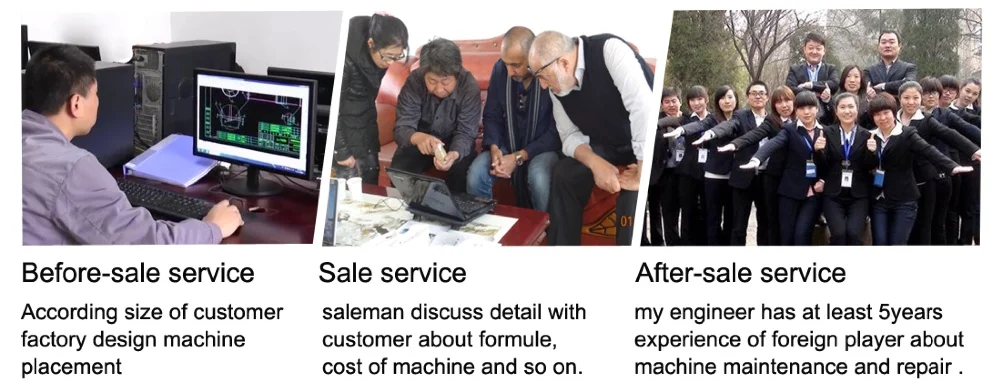

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

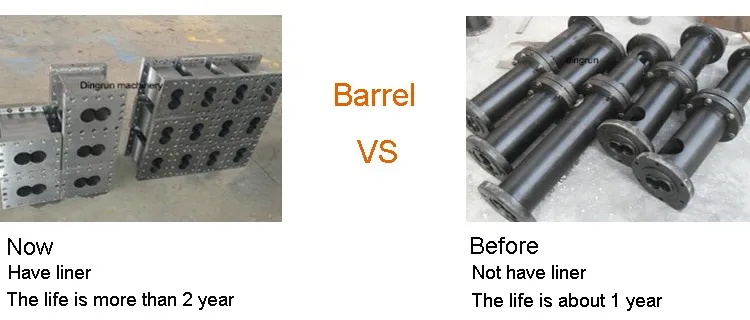

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers'

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

-

Extruder Floating Fish Feed Pellet Machine Fish Feed Pellet Machine Feed Pellet Machine Making Machine

-

Small pet food processing farm using full production forest ekibble dog food making machine

-

Fully automatic dry cold press dog food machine production extrusion granulator dog cat pet food full line

-

Stainless Steel Dog Floating Fish Chicken Animal Feed Pellet Machine Price Floating Fish Pet Food Feed Machinery

-

Commercial Automatic Core Filler Granules Dry Dog Food Extruder Making Machine Manufacturing Trading

-

50-400KG/H output diesel engine floating eel feed pellet machine dryer extruded fish feed fish pellets

-

Industrial automatic cat pet dog food manufacturing machine small dry feed extruder floating particle fish food manufacturing machine

-

Efficient Float Fish Feed Granulator Extruded Tilapia Food Making Machine 0.4-0.45T/H 220V/380V Corn Bean 37kw

-

Factory price commercial industrial fish feed pellet machine price

-

Floating Fish Feed Pellet Extruder Machine Price Fish Feed Extruder Machine Making Machine

Other Products

-

$3000.00 / set

$3000.00 / set -

$8000.00 - $25000.00 / set

$8000.00 - $25000.00 / set -

$20000.00 - $28000.00 / set

$20000.00 - $28000.00 / set -

$6000.00 - $10000.00 / set

$6000.00 - $10000.00 / set -

$6000.00 / set

$6000.00 / set -

$4000.00 / set

$4000.00 / set