instant rice production machine artificial rice processing machinery line equipment

-

Supplier: Jinan Dingrun Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Linda Tang -

Price: $25000.00 / 2 - 2 sets

$8000.00 / >=3 sets -

Min. Order: 2 sets

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Trade insurance; | Capacity: | 150-250 Kg/h; |

| Video outgoing-inspection: | Provided; | Dimension(L*W*H): | 25X5X5 M; |

| Certification: | CE ISO9001; | Automation: | high automation; |

| Port: | Qingdao Port; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Package Preview: | ; | Name: | artificial rice machine; |

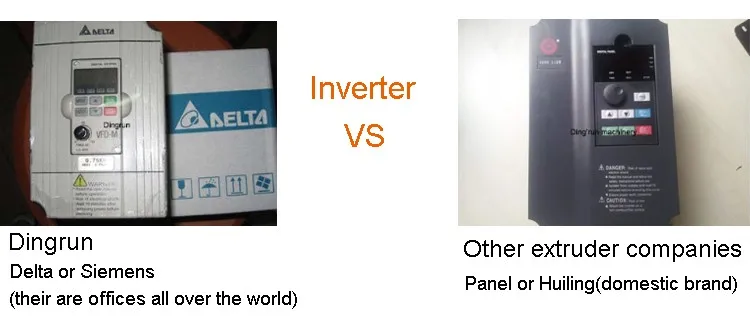

| Local Service Location: | None; | Inverter: | Taiwan Delta; |

| Installation: | as customers requirement; | Weight: | 4000KG; |

| Brand Name: | DINGRUN; | Power: | 100KW; |

| Type: | Rice Mill Production Line; | Showroom Location: | None; |

| Marketing Type: | New Product 2020; | Place of Origin: | Shandong China; |

| Phone/whatsapp: | +8618769779252; | Machinery Test Report: | Provided; |

| Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,Retail; | Main motor: | siemens; |

| Materials: | stainless steel; | Supply Ability: | 20 Set/Sets per Month artificial rice machine; |

| Warranty: | 12 Months; | Voltage: | 380V/50HZ; |

| Key Selling Points: | Automatic; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Warranty of core components: | 1 Year; | Condition: | New; |

| Production Capacity: | 200-240kg/h; | Core Components: | Gear,Gearbox,Motor; |

| Packaging Detail: | Wooden cases For artificial rice machine; |

Doritos machine

Core filling machine

Kurkure machine

instant rice production machine artificial rice processing machinery line equipment

The artificial rice processing machine adopts the broken rice, corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient, and some other vitamin and mineral as part of ingredient.The material is extruded into rice shape by the twinscrew extruder, and dried in a rotary dryer to needed moisture content. Artificial rice machine extruding technique makes it possible to strengthen and solidify the micronutrient in the rice. This artificial rice can be mixed with natural rice prior to cooking as usual. When cooking is finished, its grains are not broken and there is no difference between the artificial rice and the natural one in viscosity, elasticity and taste.

a. Raw Materials: adopts corn flour, rice powder as raw materials.

b. Products: different shapes are made by adjusting the dies from extruder

c. Capacity: 200kg/h, 350kg/h, 500kg/h, 1ton/h, 2ton/h

d. Flow chart: Mixing system---Extrusion system---Drying system---Flavoring system---Packing system

e. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

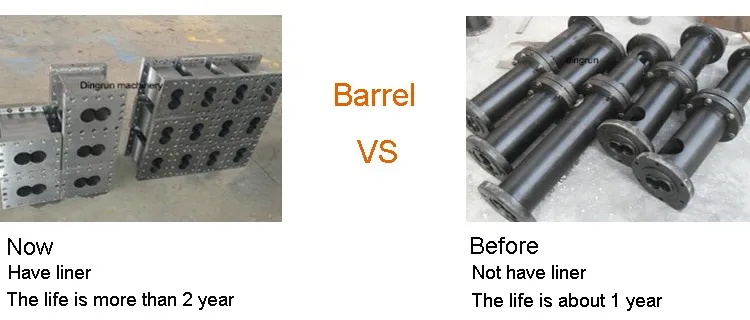

f. Machines Materials: All the artificial rice machine are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

2.Model and Parameter of artificial Rice Machine:

Model | Installed power | Actual Consumption | Main Power | Output | Dimension |

SLG65 | 34kw | 28kw | 22kw | 100-150kg/h | 2400*1200*1800 |

SLG70 | 42kw | 30kw | 30kw | 160-200kg/h | 2600*1200*1800 |

SLG75 | 85kw | 60kw | 55 | 300-360kg/h | 2600*1200*1900 |

SLG85 | 92kw | 75kw | 75 | 400-500kg/h | 4500*1600*2000 |

SLG90 | 135kw | 91kw | 75 | 800-900kg/h | 4500*2000*2000 |

3.Flow chart of artificial Rice Machine:

4.Sample of rice:

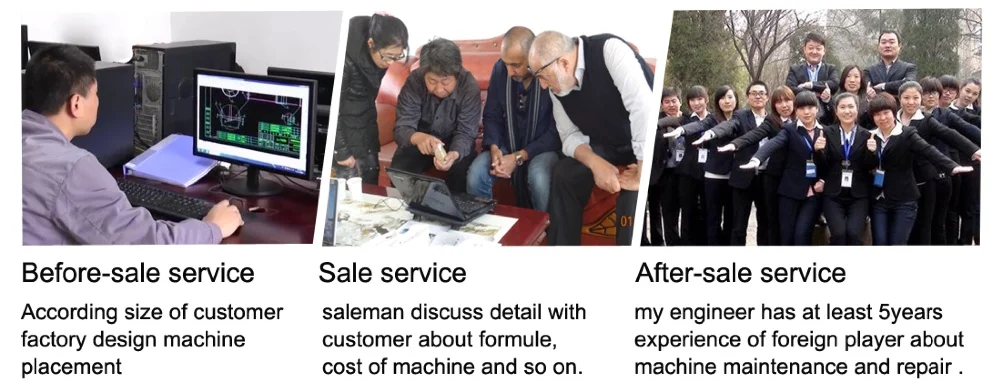

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers’

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

-

Cheap price MMJX125x5 flat rice shape grader grader 5-layer rotary screen sorter suitable for 120T rice mill

-

Household large capacity commercial small rice milling machine

-

DONGYA AGRO Rice Mill 3 in 1 Commercial 650KG PER HOUR with Lift

-

Dongya Agriculture 700KG Diesel Rice Mill 22HP Diesel Engine

-

Commercial Industrial Wet and Dry Grain Grinders Grain Grinders

-

Wholesale Complete Durable Household Combination Wheat Flour Rice Milling Machine

-

Paddy field double rice husk separating sieve/polished rice sieve

-

Rice threshing and polishing machine Rice hulling machine

-

Fully automatic multifunctional rice processing machine 260kg/h

-

DONGYA AGRO Rice Mill 3 in 1 Commercial 650KG PER HOUR with Lift

Other Products

-

$3000.00 / set

$3000.00 / set -

$20000.00 - $28000.00 / set

$20000.00 - $28000.00 / set -

$6000.00 - $10000.00 / set

$6000.00 - $10000.00 / set -

$6000.00 / set

$6000.00 / set -

$6000.00 / set

$6000.00 / set -

$4000.00 / set

$4000.00 / set