Aluminum Clamp Style Jaw / Spider Flexible shaft coupling for motor

-

Supplier: Guangzhou Hongsen Servo Motor Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Tony Xu -

Price: $0.68 / >=10 pieces -

Min. Order: 10 pieces

| Flexible or Rigid: | Flexible; | Material: | Aluminium; |

| Coupling length: | 22mm / 30mm / 35mm / 66mm / 78mm / 90mm; | Payment Terms: | L/C,T/T,MoneyGram; |

| Other name: | electric motor couplings / shaft reducer coupling; | Supply Ability: | 1000 Piece/Pieces per Day Jaw Coupling; |

| Standard or Nonstandard: | Standard; | Brand Name: | HongSen; |

| Structure: | Jaw / Spider; | Place of Origin: | Guangdong China (Mainland); |

| Coupling OD max: | 14mm / 20mm / 30mm / 40mm / 55mm / 65mm; | Product name: | Jaw / Spider Coupling; |

| Port: | Hongkong; | Packaging Detail: | Packaging Details :Standard Exporting Package; |

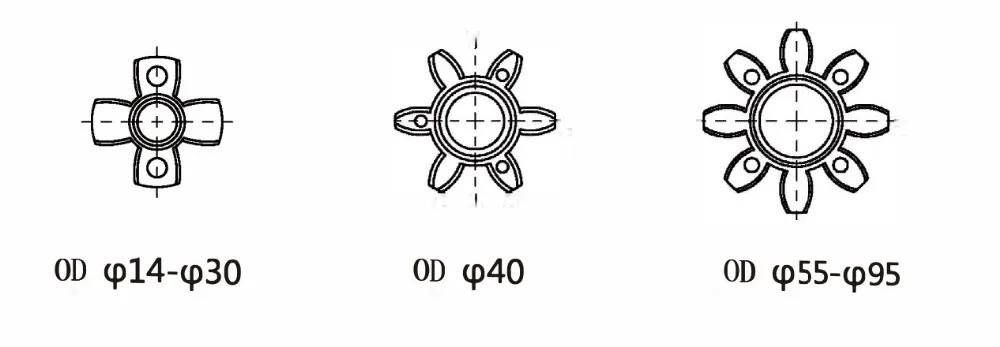

Curved Jaw Couplings

The Curved Jaw couplings can be utilized in many applications and serve as an all-purpose coupling. The basic design of the Curved Jaw allows for al higher torque capacity in a compact design. The curved tooth has a greater contact area which gives it the high torque capacity, and reduces edge pressure. It will accommodate axial, radial and angular shaft misalignments.

The hubs are produced from a variety of materials including: aluminum, gray ,iron, steel, sintered steel, and stainless steel. The spider elements are available in various durometer options in Urethane & Hytrel. The spiders can perform under normal duty cycle conditions to heavy duty cycles which include shock loading and can minimize torsional vibrations in the system.

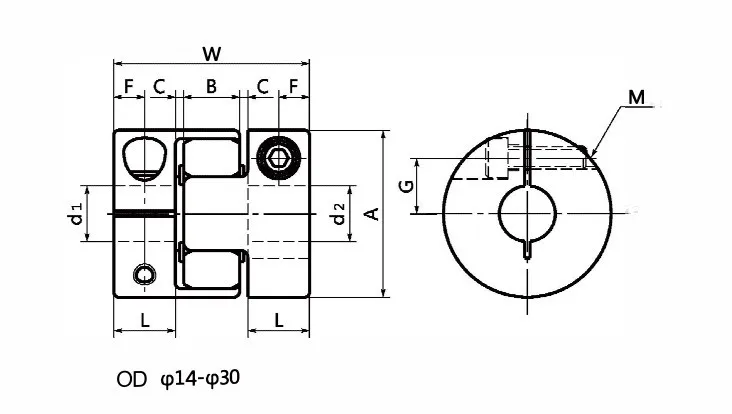

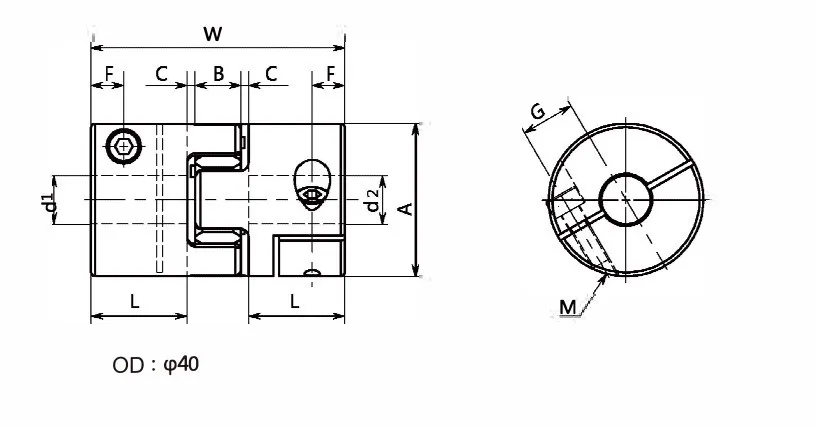

Specification

Spider Characteristics

The curved jaw coupling includes two metal hubs and an elastomeric "spider" element. The spiders are available in

different hardness durometers, each easily identified by its color.

Coupling measure information

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 1-2 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=10,000USD, 100% in advance. Payment>=10,000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

-

Flexible Coupling VS110 Rexnord-Falk VIVA Elastomer Coupling

-

L035 L050 L070 L095 rubber coupling with jaws

-

Jaws Love Joy

-

Industrial High Quality Star Flexible Shaft Coupling Claw Coupling

-

SWC-BH type high-speed universal coupling universal drive shaft

-

SLGR MINUC065 SWC-I100DH-304+30 power output cardan shaft finishing engineering machinery shaft

-

Automobile Steering System Axial Formed Alloy Steel Spline Coupling

-

Flexible gr rotex 38 KTR GS GR coupling rubber spider pad

-

Factory direct powder metallurgy sintered steel spline coupling

-

Drum Gear Shaft Coupling For High Speed Turbine Gear Coupling China Factory