Labor-saving Beverage Bottle Depalletizer Machine for Milk Glass Bottle

-

Supplier: Shanghai Lilan Packaging Technology Co., Ltd. -

Region: Shanghai, China -

Contact: Mr Eric Gu -

Price: $50000.00 /set -

Min. Order: 1 set

| Voltage: | 380V 50HZ customized; | Packaging Material: | Glass,Metal,Plastic; |

| Packaging Detail: | Labor-saving Beverage Bottle Depalletizer Machine for Milk Glass Bottle Packing Details:Film wrapping the machine and pack robot palletizer into the wooden case for this gantry palletizer.; | Equipment size: | According to The Designed Layout; |

| Type: | Packaging Line; | Automatic Grade: | Automatic; |

| Brand Name: | Lilan; | Driven Type: | Electric; |

| Warranty: | 1 Year; | Keywords: | bottle depalletizer machine; |

| Dimension(L*W*H): | 11300*5120* 5020; | Pallet size: | It is Customized 1200x1200, 1200x1000, 1000x1000; |

| Supply Ability: | 10 Set/Sets per Year bottle depalletizer machine; | Packaging Type: | Barrel,Bottles,Cans; |

| Product name: | Labor-saving Beverage Bottle Depalletizer Machine; | Weight: | 7000-10000kg; |

| Condition: | New; | Certification: | CE ISO9001; |

| Port: | Shanghai Port; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Application: | Beverage,Chemical,Commodity,Food,Medical; | Place of Origin: | Shanghai China (Mainland); |

| Max height of stack: | 1800mm It is customized; | Function: | Depalletizing,Carrying,Packing and so on; |

| Power: | 18KW (380V/3P); | Usage: | Cans, glass bottles, plastic cans, PET bottle, PE bottle and so on; |

| Payment Terms: | L/C,T/T,Western Union; | Pallet magazine: | It Can Store 15 Pallets; |

| Power: | 14kw; |

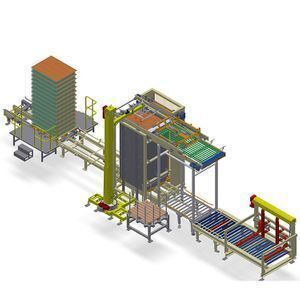

Labor-saving Beverage Bottle Depalletizer Machine for Milk Glass Bottle

This depalletizer is used to unload the empty bottles from the full stack automatically, which can improve the site working condition and production efficiency to satisfy customer’s production and packaging requirements.

Work flow:

Forklift transport the complete stack of empty bottles to the full pallet conveyor of this depalletizer, then the conveyor transport the full stack to the main lifting platform, the lifting platform lift up the full stack layer by layer; The interlayer collecting structure suck the interlayer and move it out of the stack, after that the interlayer collecting mechanism will collect the interlayers and lift it down to conveyor out of the machine when the interlayers is stored as one stack; the clamp of bottle grips the whole layer of bottles and moves them to empty bottle conveyors, repeat these actions until the all the layers are moved to the conveyor, then the lifting platform will down and output the empty pallet to the pallet magazine.

Electrical Configuration:

PLC | Siemens |

Frequency Converter | Danfoss |

Photoelectricity Inductor | SICK |

Driving Motor | SEW |

Pneumatic Components | SMC |

LOW-voltage Apparatus | Schneider |

Touch Screen | Schneider |

| Servo | Panasonic |

Stack Speed | 400/600/800/1200 bottles per minute |

Max. carrying capacity /layer | 150Kg |

Max. carrying capacity /pallet | Max 1500kG |

Max. stack height | 1800mm (Customized) |

Installation Power | 18KW |

Air Pressure | ≥0.6MPa |

Power | 380V.50Hz , three-phase +ground wire |

Consumption of the Air | 800L/Min |

Size of the Pallet | According to customer reqirement |

After Sales Protection:

1. Ensure outstanding quality

2. Professional engineers with more than 7 years experience, all in readiness

3. Available on-site installation and debugging

4. Experienced foreign trade staff to guarantee instant and efficient communication

5. Provide lifelong technical support

6. Provide operation training if necessary

7. Quick response and in-time installation

8. Provide professional OEM&ODM service

VALIDITY OF THE OFFER

30 days from the date of quotation sent

DELIVERY

Approx. 60 days from order confirmation

PAYMENT

30% as deposit by T/T, 70% paid before shipment by T/T.

INSTALLATION &COMMISSIONING

The seller will dispatch one engineer to the buyer's factory for installation and commissioning and training, the buyer should be responsible for the room and board and the go-back air tickets and visa fee, and the allowance of 100 USD per day for each person each day.

NOTE

1. If delays occur due to the fault of either party involved, then any extracost shall be borne by the party at fault

2. The Customer is responsible for providing continuous supply of quality electricity for the duration of the installation, commissioning and test running, which must be available prior to the arrival of technicians from the Manufacturer.

SAMPLES

Sufficient quantity of product samples must be sent byCustomers toManufacturerwithin 15 days after order confirmation for technical clarification.Delays in sending the required samples may affect the delivery schedule of the machines, of which the Manufacturer bears no responsibility for the cost of sending the samples is at Customer's charge.

GUARANTEES

√ The guarantee covers the replacement f.o.c. of the parts that are comprised in the supply and those

acknowledged to bear manufacturing faults or are materials that contribute to the incorrect function of

the machine

√ Lilan guarantees the products supplied for a 12-month period as of from the date of the startup but

however, not more than 18 months from the date of the relative invoice.

√ As for the electrical and electronic parts, the guarantee lasts for 6 months from the startup date but

however, not more than 12 months from the date of the relative invoice.

√ Merchandise that is supplied under guarantee will be delivered with pre-paid freight and packaging

√ Other relevant guarantees kindly see the operation and appliance manuals sent with equipment.

Note:All the accurate technical data should be confirmed in the meantime contract is confirmed

-

Metal can end making machine/can end production line

-

High-speed automatic carton cartoon box folding gluing machine corrugated carton carton gluing machine

-

Fully automatic high-speed vertical carton packaging food pizza bottle soap gloves plastic carton box packing machine

-

Carton Liner Bag in Box Line for Packaging Margarine Butter Semi-Liquids

-

Fully-automatic Bag in Box Filling Packaging Line

-

A full set of automatic filling and sealing pure drinking sachet water packaging line

-

Y-Pack buy kn94 n95 facial mask carton packaging machinery automatic cartoning machine cartoning machine

-

Fully automatic single-sided e-groove corrugated cardboard carton carton product making machine

-

Best Selling Automatic Premade Bags Automatic Filling Sealing Packaging Machine

-

50-220L steel drum/barrel making machine

Other Products

-

$100000.00 / set

$100000.00 / set -

$50000.00 / set

$50000.00 / set