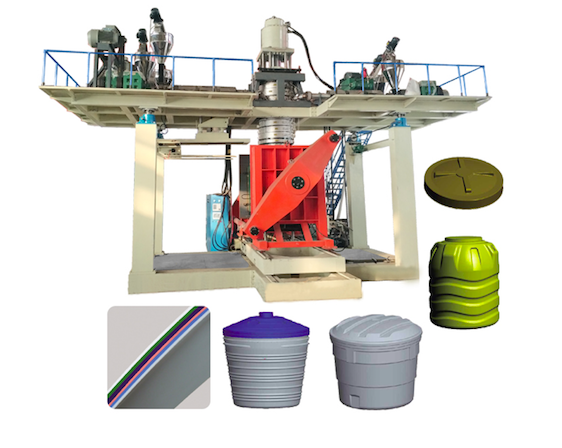

plastic machine for the production of water tanks

-

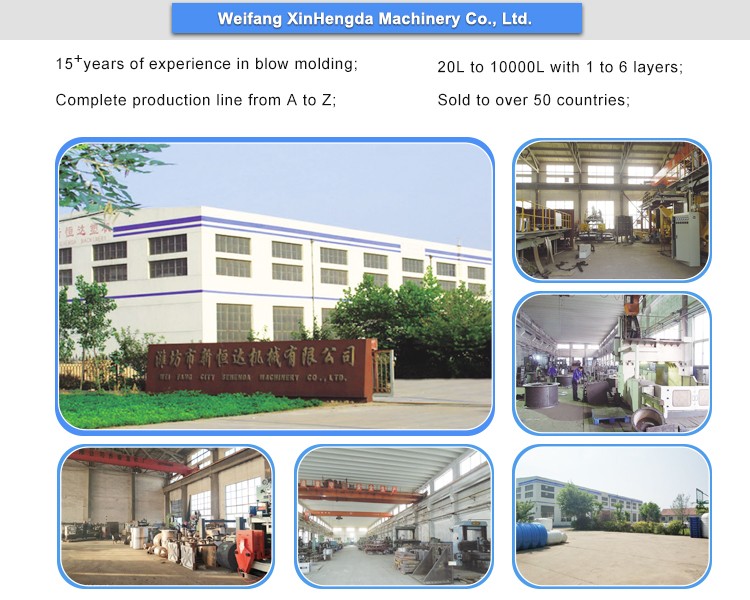

Supplier: Weifang Xinhengda Machine Co., Ltd. -

Region: Shandong, China -

Contact: Mr Jerry Liu -

Price: $70000.00 /set -

Min. Order: 1 set

| Power (kW): | 350 | type: | Extrusion blow molding equipment |

| port: | Qingdao | Health status: | new |

| Voltage: | 380-415V | PLC brand: | Siemens |

| use: | large water tank | Air pressure (MPa): | 0.65 MPa |

| Showroom location: | not any | Key words: | Plastic water tank making machine |

| Mechanical test report: | if | product name: | Fully automatic bottle blowing machine |

| Number of screw heating zones: | 7 | Extruder motor power (kW): | 90 kilowatts |

| Output (kg/hour): | 600kg/hour | Warranty: | 1 year |

| Screw aspect ratio: | 30 | Name: | Plastic jar blow molding machine |

| Video outbound inspection: | if | Plastic processing: | High-density polyethylene, polyethylene, high-density polyethylene/polypropylene |

| Package preview: | Supply capacity: | 35 sets per year | |

| Clamping force (kN): | 2200 | Weight (tons): | 70 |

| Material: | High-density polyethylene | Screw diameter (mm): | 120mm |

| Production: | HDPE extrusion blow molding machine | Template size (width) (mm): | 1900mm |

| Blow molding type: | Extrusion blow molding machine | After-sales service provided: | engineer |

| automation: | automatic | Applicable industries: | Building materials stores, food and beverage factories, farms, restaurants, home use, construction projects, machinery repair shops, manufacturing factories, others |

| Main selling points: | Polychromatic | Accumulator capacity (L): | 120 liters |

| Core component warranty: | 3 years | Packaging details: | open top container |

| brand: | Sehenda | Screw heating power (kW): | 40kW |

| Place of origin: | Shandong Province, China | Dimensions (length*width*height): | 11*5*8 |

| Air consumption (m3/min): | 6 cubic meters/minute | Die heating power (kW): | 100 kilowatts |

| Template size (height) (mm): | 2100mm | payment terms: | Letter of credit, wire transfer |

| Core components: | Die head |

Plastic water tank making machine

1.Machine

2. Blow molding machine plastic production:

3. Product details

Fully automatic plastic blow molding machine

-The screw adopts IKV design, and the high-efficiency melt ensures that the materials are fully mixed.

-The motor system adopts variable frequency speed regulation to reduce power consumption.

-Using Moog 200-point parison thickness controller to make the wall thickness uniform and adjust the tank weight over a large span.

- Fully automatic and easy to operate, two women can operate the machine, and the entire production line only requires 3 or 4 people.

- High output compared to rotational molding machines

-Save raw materials by 25% - 35% compared to Roto tanks.

-Perfect impact resistance compared to Roto tanks.

-The robotic arm can automatically take out products

4.Host

|

Low voltage electrical appliances |

Siemens |

|

|

pneumatic |

STNC & Airtac |

|

|

Hydraulic Components |

Yuken |

|

|

seal |

DICHTOMATIK Germany and Taiwan DZ |

|

|

screw motor |

Siemens |

|

|

Proximity switch |

Korea Autonics |

|

|

PLC |

Siemens |

|

|

temperature control |

Siemens |

|

|

touchscreen |

Japanese PROFACE |

|

|

Linear Guides |

Taiwan Bank of China |

|

|

Wall thickness control system |

Mog |

|

|

Frequency converter |

ABB |

|

|

Gearbox |

Jiangyin gear |

|

|

electronic scale |

jefran italy |

|

|

Servo system (standard configuration) |

||

|

Servo oli motor |

italian photo |

|

|

Servo Control |

Delta Taiwan |

|

|

Servo oil pump |

Sumitomo Japan |

|

5. Machine loading

6. Quality assurance, training, installation and adjustment

The products and services we offer are guaranteed to the highest quality and performance. We are guided by strict quality control policies adopted by our management. As per the above policy, all our products are tested on different parameters to ensure their perfect quality.

The buyer can send operators to the seller’s factory for training, including machine operation, maintenance and simple repairs;

Or according to the buyer's requirements, the seller's technical personnel can go to the buyer's factory to train the buyer's operators during installation and commissioning;

Training is free;

The seller can send an engineer to the buyer's factory for one week of machine installation and debugging according to the buyer's requirements.

Buyers should make an appointment in advance before shipping;

The buyer needs to pay the engineer visa application fee, round-trip air tickets, food and accommodation expenses before the engineer departs;

7. Guarantee

If the problem is caused by quality control or any reason from the seller, the warranty period is one year after the machine works normally in the buyer's factory. We will provide replacement parts for free and our engineers will guide you how to solve the problem.

8. Xinghengda Factory

-

Extrusion Plastic Blow Molding Machine Automatic High Speed Extrusion Blow Molding Machine HDPE PE PP PC PETG LDPE

-

Fully automatic plastic bottle blow molding machine with favorable price

-

Juice plastic popsicle tubes in different shapes

-

HDPE 1 Liter 5 Liter View Stripe Lubricant Lubricating Engine Oil Plastic Bottle Manufacturing Extrusion Blow Molding Blow Molding Machine Price

-

Plastic Mannequin Extrusion Blow Molding Machine

-

Blow molding machine Hdpe

-

Barrel Making Machine 90L 100L 120L Plastic Barrel Molding Machine 230L 210L 200L 160L

-

4L/5L Used Extrusion Blow Molding Machine With Parison Control Used Plastic Bottle Blow Molding Machine

-

blow molding machine with plastic extrusion

-

5000L HDPE water tank three-layer blow molding machine

Other Products

-

$100000.00 / set

$100000.00 / set