Fabric, Foam, Velvet Automatic Fabric Coating Machine Made in China

-

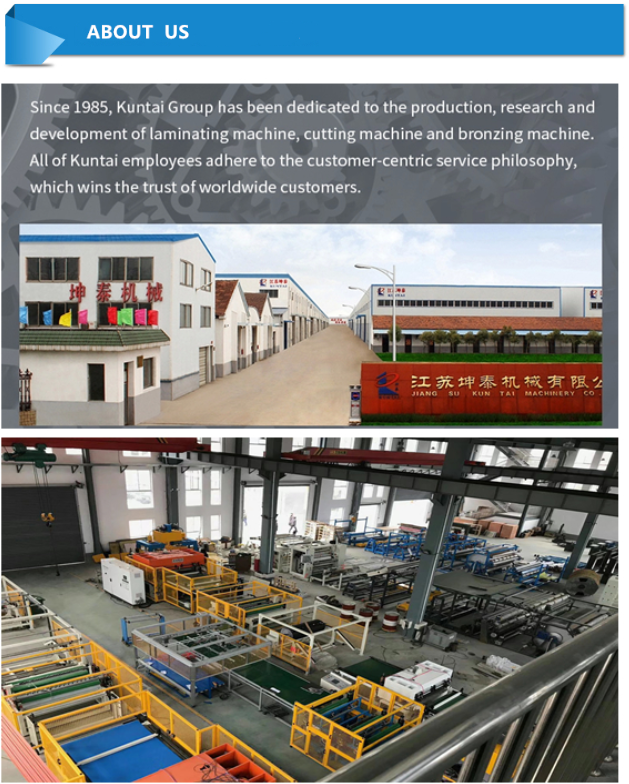

Supplier: Jiangsu Kuntai Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Annie Lv -

Price: $69800.00 / 1 - 2 sets

$69000.00 / >=3 sets -

Min. Order: 1 set

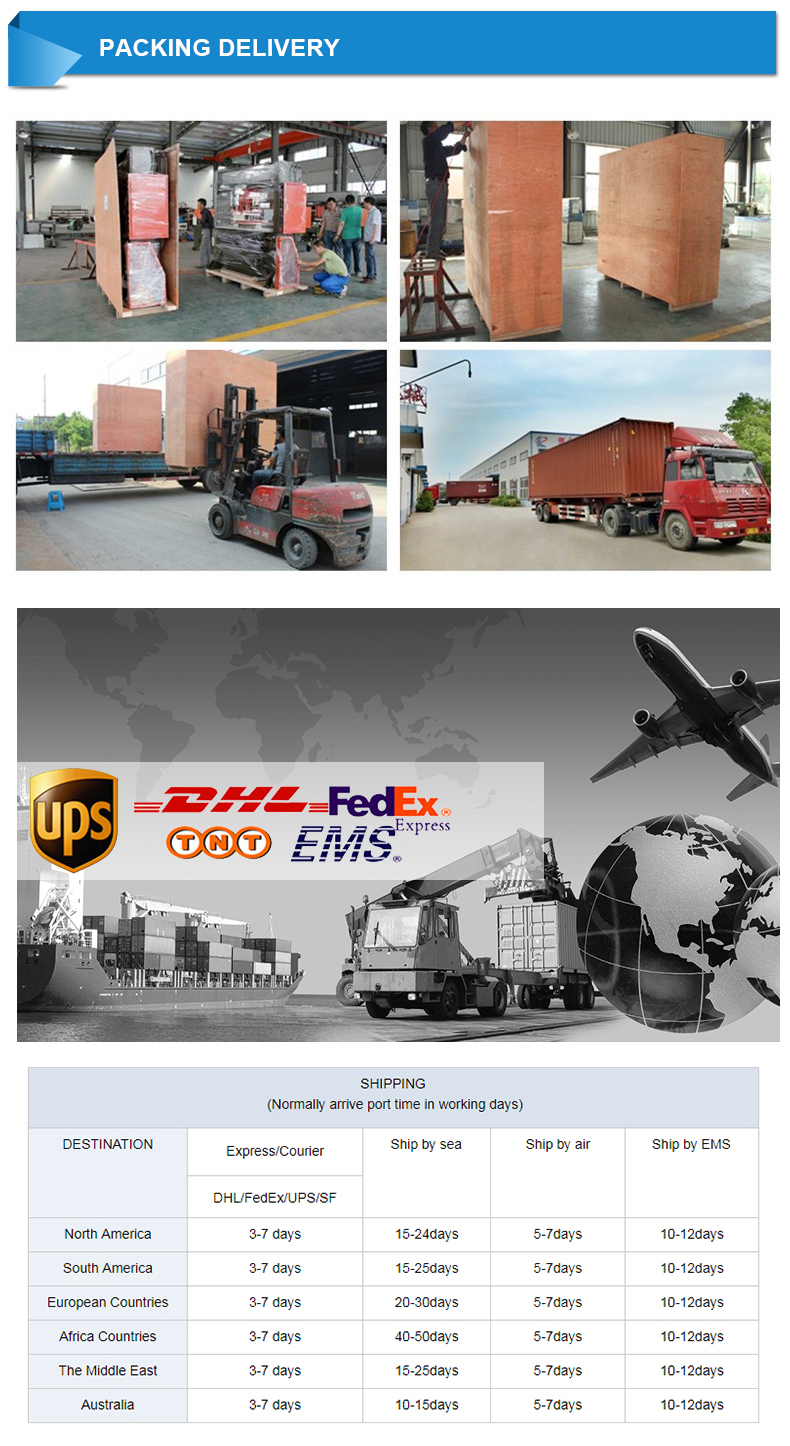

| Showroom location: | not any | Packaging details: | Export standard packaging |

| Applicable industries: | manufacturing plant | Core components: | Engines, motors, pumps |

| Maximum coating width: | 1600mm/1800mm/2400mm/can be customized | Video outbound inspection: | if |

| strength: | 45kW, 50kW | Post-warranty service: | Video technical support, online support, spare parts |

| brand: | Kuntai | Production capacity: | 50kW |

| After-sales service provided: | Free spare parts, video technical support, online support | Supply capacity: | 50 sets per month |

| weight: | 11500kg | Health status: | new |

| Marketing type: | 2020 new products | Warranty: | 1 year |

| Package preview: | Certification: | CE | |

| Type of machine: | Laminating machine | application: | Fabric, foam, velvet coating machine |

| feature: | Automated, efficient, multifunctional | Lamination speed: | 5~50m/minute |

| Place of origin: | Jiangsu, China | Local service locations: | not any |

| Mechanical test report: | if | Automatic level: | automatic |

| port: | Shanghai | usage: | Leather/fabric/non-woven fabric/textile/PU/PP/aluminum foil/glass wool, etc. |

| payment terms: | L/C, Western Union, T/T | Voltage: | 220V/380V/can be customized |

| Dimensions (length*width*height): | 11600×3400×3700mm | Core component warranty: | 1 year |

| glue: | Polyurethane glue |

Fabric, Foam, Velvet Automatic Fabric Coating Machine Made in China

application:

Hot melt adhesive lamination coating machine is suitable for:

1. EVA+PVC, PU or artificial leather

2. EVA + Fabric (for shoe materials, etc.)

3. Neoprene + fabric (for wetsuits, etc.)

4. PU foam + fabric (for bras, car mats, etc.)

5.TPU film + fabric. (for mountaineering clothing, camouflage clothing, etc.)

6. Fabric + fabric. (for clothing, medical supplies, etc.)

Hot melt glue:

Hot melt adhesives offer several advantages over solvent-based adhesives in industrial applications. volatile

Organic compounds are reduced or eliminated, and drying or curing steps are eliminated. hot melt advertising

-hesives have a long shelf life and can usually be handled without special precautions.

The most advanced hot melt adhesive, moisture reactive hot melt adhesive (PUR & TPU) with high viscosity

And environmentally friendly. Can be used for laminating 99.9% of textiles. Laminate is

Soft and heat resistant. After hygroscopic reaction, the material is less susceptible to environmental influences

temperature. In addition, laminates offer long-lasting elasticity and are resistant to wear, oil, and corrosion.

resistance. In particular, PUR's mist properties, neutral color and other characteristics make it a good choice for medical

- Can be used for cal industrial applications.

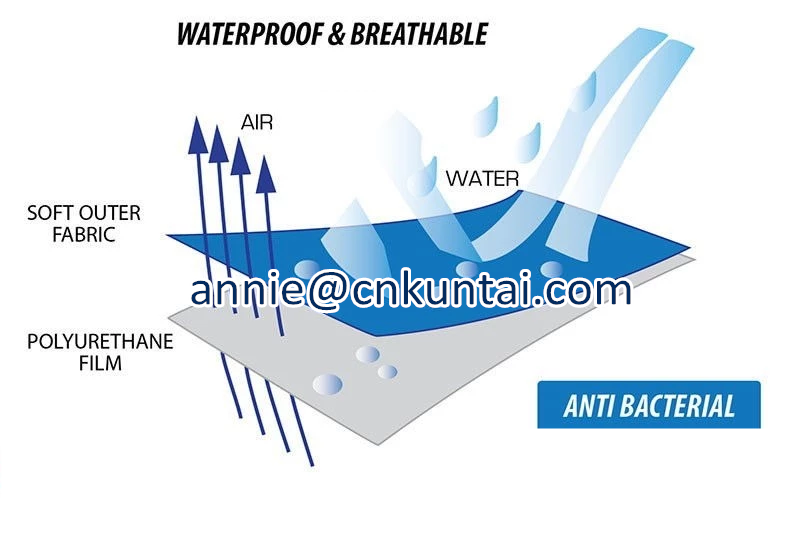

When laminated with functional waterproof and breathable films such as PTFE, PE, and TPU, water

- Heat insulation, waterproof protection, oil, water and gas filtration, etc.

New materials will be created. The needs of the clothing industry, motor manufacturing, and medical industries,

The environmental protection industry will be satisfied.

Our hot melt laminating machine mainly consists of fabric winding and unwinding units, fabric and film

Transport systems and tension controllers, film unwinding and lining or film carrier rewinding units, thermal

Melting device (optional), pump (optional), thermal oil source system (optional), glue point transfer

Unit, laminating device, cooling device, PLC and other devices. It has compact structure, high degree of automation and easy operation

maintain.

Options:

1. Accumulators for foam, textiles, backings, etc.

2. Trimming device

3. Inspection machine

4. Swinging device to swing the final laminate into piles

5. Cutting machine

Standard technical parameters (can be customized):

| Model: | KT-PUR-1800 |

| Maximum material width: | 1600mm |

| Machine drum width: | 1800mm |

| Glue amount: | 5-80g/m2 |

| Machine speed: | 10-60m/min |

| strength: | 45.0kW |

| Current and voltage: | customizable |

| Estimated net weight: | 11500kg |

| Estimated dimensions: | 11800×3400×3700mm |

Main features:

- Hot melt adhesive makes environmentally friendly products possible, making the entire lamination process pollution-free.

- Using this laminating machine, the materials are firmly bonded and the product is soft, comfortable, washable and breathable.

- The machine is controlled by a touch screen programmable controller system, with a modular design structure and simple and convenient operation.

- Famous brand motors and frequency converters can be installed, and the machine performance is stable.

- The tension-free unwinding device makes the laminate smooth and flat, ensuring good bonding effect.

- Fabric and film openers also allow smooth, smooth material feeding.

- For four-way stretchable fabrics, a special fabric transfer/delivery system can be installed on the laminator.

- Parallel centering device ensures that materials are fed in sequence.

- The specially designed glue application system can control the amount of glue applied well and ensure accuracy.

- The temperature control of the hot melt glue melting machine is accurate and stable.

- The final laminate can be re-rolled into small or large rolls.

- Low maintenance cost and low operating noise.

- Advanced technology, reliable quality control and satisfactory after-sales service make our laminators the first choice of customers at home and abroad.

More Kuntai machines:

-

PU PP non-woven fabric laminating machine

-

Full Automatic Vinyl Hot and Cold Laminator Laminating Machine A4 A3

-

Textile PUR Hot Melt Adhesive Laminating Machine

-

High-efficiency automotive interior leather processing and laminating hot pressing laminating machine

-

2020 Cloth Folding Machine Thermal Leather Glue Applicator

-

Original PUR hot melt adhesive laminating machine breathable film TPU film PTFE PU

-

High Speed Flame Composite Machine Fabric Bonding Machine Automatic Sponge Composite Bonding Machine

-

DC-380C fit width 360mm anti-curling

-

Hydraulic leather shaking head cutting shoe press machine

-

Hot Melt Adhesive Laminating Machine/Cloth Laminating Machine

Other Products

-

$64000.00 - $72500.00 / set

$64000.00 - $72500.00 / set -

$34780.00 / set

$34780.00 / set