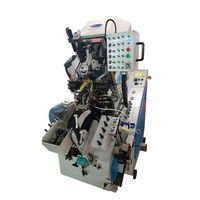

Small Production Automatic Shoe Cement Toe Last Shoe Making Machine Price

-

Supplier: Foshan Dafeng Machinery Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Lucy Luo -

Price: $9999.00 /set -

Min. Order: 1 set

Product details

| Core components: | PLC, bearings, gearboxes, motors, pressure vessels, pumps | Dimensions (L*W*H): | 1700*1000*1950mm |

| Key words: | Chinese shoe machine | Automatic level: | semi-automatic |

| Packaging Details: | Packed in wooden boxes or pallets, suitable for long-distance transportation and adaptation to climate change, moisture-proof and shock-proof. | Package preview: | |

| Voltage: | 380V | port: | Guangzhou Port Shenzhen Port |

| brand: | Dafeng | Showroom location: | Indonesia |

| Function: | innovative mechanical structure | pliers: | 9 paws |

| Machine name: | Upper machine | payment terms: | L/C, Western Union, D/P, T/T |

| Marketing Type: | 2020 New Products | Certification: | CE |

| Mechanical test report: | if | weight: | 1100 |

| Name: | Toe last machine-made shoes | application: | make shoes |

| Origin: | Guangdong, China | feature: | Adjustment made easier |

| Production: | Automatic last | Warranty: | 1 year |

| After-sales service provided: | Video technical support | Production capacity: | High |

| Health status: | new | Core component warranty: | 1 year |

| Video outbound inspection: | if | After Warranty Service: | spare parts |

| Applicable industries: | manufacturing plant, shoe machine, shoe making machine | strength: | 2.7 kW |

| type: | Automatic shoe fixing machine | Supply capacity: | 100 sets per month |

Fully Automatic Hydraulic Shoe Upper Machine Sports Shoes Shoe Making Machine

Automatic sticky toe machine

Full hydraulic operating system. Nine micro-adjustable and quick-change pliers are mounted on a dual tracking nipper.The left and right last pliers automatically flip inwards for added inner lasting perfection. Each set of left and right last pliers can be set to pull automatically or manually to prevent shoe uppers of different materials from being pulled on only one side. The upward stroke of the last support can be adjusted by the external knob. The last support has a two-stage upward movement function, combined with the movement of the heel support, to prevent the last from slipping. The width of the glue applicator can be quickly adjusted to achieve the perfect glue point. The insole can be adjusted according to different shoe sizes. The toe push mechanism is designed with adjustable two-stage pressure. During the motion of the initial pressure,

There are two ways (pressure control or position control) can be set for optimal operation. The forward movement of the wipers is adjustable with infinitely variable control. Standard equipment: auxiliary wiper mechanism, auxiliary side thruster mechanism and front toe mechanism.

There are two ways (pressure control or position control) can be set for optimal operation. The forward movement of the wipers is adjustable with infinitely variable control. Standard equipment: auxiliary wiper mechanism, auxiliary side thruster mechanism and front toe mechanism.

Model | Dimensions (length, width and height) | Package size (length, width and height) | weight | Production | strength | Voltage |

DF-N737A | 1700*1000*1950 | 1800*1160*2100 | 1100 kg | 1600 pairs/8 hours | 2.7 kW | 380V |

Shoe machine application

shoe manufacturing process

VIEW MORE

You may like

-

Factory price high quality shoe upper making machinery 7 claw hydraulic automatic shoe toe machine

-

Refurbished second-hand Chenfeng hydraulic shoe toe and heel machine

-

Automatic Leather Shoes Upper Boots Hot Press Forming Machine

-

9 pliers computer memory control automatic servo gluing back upper mechanism shoe machinery

-

Shoe mold making machine automatic hydraulic computer consolidation shoe toe heel machine

-

Toe Lasting Machine Price Vending Machine Shoe Automatic Lasting Machine

-

Hydraulic Automatic Sports Shoes School Shoes Back Knot Shoe Making Machine

-

Automatic Lasting Machine Price Lasting Machine Spare Parts Lasting Machine

-

Shoe making machine Pneumatic snow boot toe forming machine

-

Factory price hot melt glue shoe last machine automatic shoe last sticking machine

Other Products

-

-

-

$1860.00 / set

$1860.00 / set -

$5000.00 - $5200.00 / set

$5000.00 - $5200.00 / set -

$4999.00 / set

$4999.00 / set -

$1424.92 / set

$1424.92 / set -

$1080.00 / set

$1080.00 / set -

$511.07 / set

$511.07 / set -

$2503.80 / set

$2503.80 / set -

$5951.20 / set

$5951.20 / set

Related Search

computerized automatic cementing toe lasting machine

automatic shoe cover machine

fully automatic shoe washing machine

shoe making machines

plastic shoe making machines

industrial automatic candle making machine price

automatic screw making machine price

automatic paper cup making machine price

automat shoe last process 2012 suppliers

shoes machine toe lasting machine