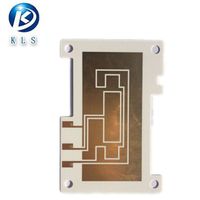

0.635 mm 96% AL2O3 ceramic PCB with printed resistors printed directly on board

-

Supplier: Shenzhen Danyu Electronics Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Peter Gui -

Price: $1.99 / 100 - 499 pieces

$1.49 / >=500 pieces -

Min. Order: 100 pieces

Product details

| Copper thickness: | 10-20 microns | Substrate: | AlN/Si3N4/Al2O3(96%)/ZTA(ZrO29%) |

| Origin: | Guangdong, China | Packaging Details: | 10pcs/box, 10boxes/carton |

| Solder Mask: | No | product name: | AMB ceramic PCB |

| minute. Line spacing: | 0.15 mm | brand: | Danyu |

| model: | DSC00509 | Plate thickness: | 0.635mm |

| type: | Ceramic PCB | Silkscreen: | No |

| minute. Hole size: | 0.10 mm | Operating temperature: | -55℃~650℃ |

| Maximum Copper Thickness: | 800 microns | Board size: | Customization |

| Surface treatment: | ENEPIG | Material: | Silicon nitride |

| Certificate: | ISO13485/IATF16949/ISO9001/UL | Copper thickness: | 0.6 mm (600 microns) |

| Shipping method: | DHL UPS EMS TNT FedEx | minute. line width: | 0.15 mm |

| port: | Yantian | application: | New energy vehicle IGBT module |

| payment terms: | Western Union, T/T |

Product Description

The conductor thickness of this ceramic PCB is 5-7um gold paste

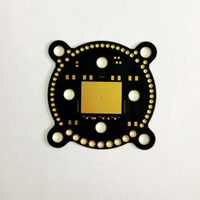

This is a ceramic PCB made with AMB (Active Metal Brazing) technology with very thick copper

This AMB ceramic PCB with plated through holes

This ceramic PCB substrate is 0.635mm 96% AL2O3

Compared with DBC technology, AMB technology has stronger thermal conductivity, heat resistance and impact resistance

The ceramic PCB is double-sided

This is a very good and suitable ceramic PCBmedical device

about Us

Major equipment

Customer visit

Manufacturing capacity

thing | Thick film capability | DCB/DBC capability | data transfer capability | Magnetic Bearing Capability | |||

layers | 10 floors | 2 layer | 2 layer | 2 layer | |||

board size | 200*200mm | 138*178mm | 138*190mm | 114*114mm | |||

Minimum plate thickness | 0.25 mm | 0.30mm~0.40mm | 0.25 mm | 0.25 mm | |||

Maximum plate thickness | 2.0 mm | 1L: 1.3mm; 2L: 1.6mm | 2.0 mm | 1.8 mm | |||

Conductor Thickness | 5 microns - 13 microns | 3.9 oz - 8.6 oz | 2 microns-200 microns | 8 oz - 22.9 oz | |||

Minimum Line Width/Space | 6/8 mil (0.15/0.20 mm) | 12/12 mil (0.30/0.30mm) | 6/8 mil (0.15/0.20 mm) | 20/20 mil (0.50/0.50 mm) | |||

Substrate type | AI203, ALN, BeO, ZrO2 | AI203, ALN, ZrO2 | AI203, ALN, ZrO2, Si3N4 | Aluminum Nitride, Silicon Nitride | |||

Substrate thickness | 0.25, 0.38, 0.50, 0.635, 0.80, | 0.25, 0.38, 0.50, 0.635, 0.76, | 0.25, 0.38, 0.50, 0.635, 0.80, | 0.25, 0.38, 0.50, 0.635, 0.76, | |||

1.0, 1.25, 1.5, 2.0mm | 1.0 mm | 1.0, 1.25, 1.5, 2.0mm | 1.0mm | ||||

minimum aperture | 4 million (0.1mm) | ||||||

Minimum pitch | NPTH: 16mil (0.30mm); PTH: 20mil (0.5mm) | ||||||

Minimal pad ring (single) | 6 million (0.15mm) | not applicable | 3 million (0.075mm) | not applicable | |||

Plated Through Hole Wall Thickness | 4 million (10 microns) | not applicable | 4 million (10 microns) | not applicable | |||

Minimum Pad Diameter | 10 million (0.25mm) | 8 million (0.20mm) | 6 million (0.15mm) | 8 million (0.20mm) | |||

Minimum Solder Bridge | 12 million (0.30mm) | 8 million (0.20mm) | 6 million (0.15mm) | 8 million (0.20mm) | |||

Minimum BAG PAD margin | 12 million (0.30mm) | 8 million (0.20mm) | 5 million (0.125mm) | 8 million (0.20mm) | |||

PTH/NPTH diameter tolerance | Plated Through Hole: ±4 mil (0.1 mm); NPTH: ±2 mil (0.05 mm) | ||||||

Hole position deviation | ± 4 mil (0.1 mm) | ||||||

Shape Tolerance | Laser: +0.2/0.05mm; | Laser: +0.2/0.05mm | Laser: +0.2/0.05mm; | Laser: +0.2/0.05mm | |||

Die: +0.25/0.20mm | Die: +0.25/0.20mm | ||||||

Line Width/Space Tolerance | ± 5 mil (0.125 mm) | ± 5 mil (0.125 mm) | ± 1 mil (0.025 mm) | ± 5 mil (0.125 mm) | |||

surface treatment | Silver palladium, gold palladium, manganese/nickel | OSP/nickel plating, ENIG | OSP/ENIG/ENEPIG | OSP/nickel plating, ENIG | |||

Thermal Stress | 1 hour @350℃ | 3 x 10 sec @ 280°C | 15 minutes @350℃ | 3 x 10 seconds @ 280°C | |||

Advantage

Packaging and Shipping

Customer Reviews

VIEW MORE

You may like

-

Fuel meter resistor chip fuel power resistor board resistor chip circuit board customization - manufactured fuel meter thick film circuit

-

Ceramic PCB Shenzhen black yellow green gold red white blue copper button mask silk screen electronic layer surface solder ROHS

-

DBC ceramic substrate DPC film double-sided circuit board

-

High Quality Custom Product Bom Gerber Quote Multilayer Aluminum Nitride Substrate PCB Supplier Ceramic PCB Manufacturer

-

2L DBC Ceramic PCB Circuit Thick Film Multilayer Aluminum Ceramic Substrates Heavy Duty Copper Strip

-

Black porcelain aluminum nitride ceramic substrate High thermal conductivity Strong bonding force High insulation

-

Custom ceramic PCB supplier from electronic component factory offers PCB prototype

-

Factory selling all kinds of custom lap board Pcb circuit board Pcb supplier

-

Non-toxic and harmless environmental protection aquarium coral debris plug ceramic base

-

High frequency ceramic pcb antenna prepreg pcb

Other Products

-

$0.40 - $0.60 / piece

$0.40 - $0.60 / piece -

$0.30 - $0.50 / piece

$0.30 - $0.50 / piece