Prefabricated hollow panel/sandwich panel production line/prefabricated concrete mold for prefabricated board room

-

Supplier: Ningjin County Shuangli Building Materials Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Mr shuangli zhan -

Price: $3500.00 /set -

Min. Order: 1 set

| Supply capacity: | 50 sets per month | Voltage: | 380 volts |

| Main selling points: | easy to operate | Applicable industries: | Building material stores, construction projects |

| Warranty: | 1 year | raw material: | cement stone sand |

| Production capacity: | 60~65m/hour | payment terms: | wire transfer |

| strength: | 10.5 kW | After Warranty Service: | Video Technical Support |

| brand: | Ling Feng | After-sales service provided: | online support |

| Automatic level: | automatic | feature: | high density structure |

| Video outbound inspection: | if | application: | build house |

| Origin: | Shandong Province, China | Core component warranty: | 1 year |

| Alloy Thickness: | 1.5 mm | Mechanical test report: | if |

| Marketing Type: | Hot Products of 2019 | weight: | 2.5 kg |

| Use 1: | Hollow plate machine | color: | yellow or customized |

| Showroom location: | not any | Business Scope: | worldwide |

| Health status: | new | Packaging Details: | Concrete Prefabricated House Precast Concrete Mold Hollow Panel Machine --- Tarpaulin Packaging |

| Use 2: | Prefabricated trigger | Aperture: | 76mm |

| Core components: | engine, motor | Package preview: | |

| Dimensions (L*W*H): | 2.5*1.15*1m | port: | Qingdao Port |

| hole: | 4 |

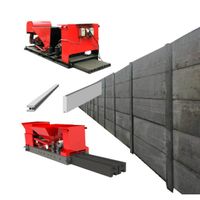

200*600Concrete Hollow Slab Forming/Making Machine For Sale

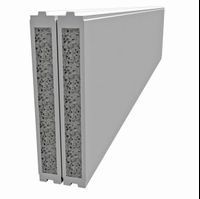

The cement hollow slab molding machine works on the long-line workbench, guided by high-strength and low-relaxation steel strands, and adopts the push-push working method to form concrete hollow slabs. The slab has the advantages of smooth surface and high structural density. Concrete hollow slabs are mainly used in factories with large bays, schools, hospitals, shopping malls, office buildings, bulk warehouses, etc.

Brief Introduction of Precast Precast Concrete Slab Machine-

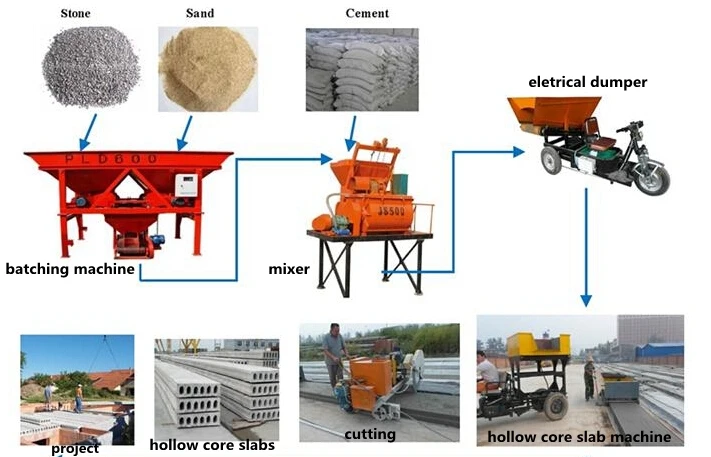

1. Material mixing system

2. Prestressing system, (straightening steel strands in precast concrete slabs)

3. Material transportation (using concrete dump tricycle)

4. Prefabricated prestressed concrete panel machine (concrete panel machine working system)

5. Concrete slab cutting system. (concrete slab cutting machine)

Production process of prefabricated prestressed concrete slab production line-

Strength of Precast Prestressed Concrete Slabs-

1.Advanced and mature prefabricated prestressed concrete slab production line technology

2. Fast forming speed of prefabricated prestressed concrete slab machine: 1.2-1.4m/min

3. Low labor intensity and high efficiencyPrefabricated prestressed concrete slab production line

4. The prefabricated prestressed concrete panel machine has a long service life

Slab machine-

|

Model |

strength (kilowatt) |

aspect (rice) |

Hole |

Voltage (five) |

Maximum load twisted wire |

speed (m/h) |

weight (Ton) |

|

200*600 |

10.5 |

2.3*1*0.9 |

4 |

380 |

12.7mm*5 |

65~70m/h |

2.3 |

|

200*900 |

15 |

2.7*1.15*1 |

5 |

380 |

12.7mm*7 |

60~65m/hour |

4 |

|

250*900 |

18.5 |

3.8*1.15*1 |

5 |

380 |

12.7mm*7 |

60~65m/hour |

4.5 |

|

150*900 |

15 |

2.6*1.6*1 |

9 |

380 |

12.7mm*12 |

65~70m/h |

3.8 |

|

300*900 |

number 22 |

3.36*1.15*1.2 |

5 |

380 |

12.7mm*6 |

60~65m/hour |

5.5 |

|

300*1200 |

36 |

3.5*1.85*1.2 |

6 |

380 |

12.7mm*12 |

60~65m/hour |

6 |

|

150*1200 |

18.5 |

2.9*1.5*1 |

13 |

380 |

9.5mm*14 |

65~70m/h |

3.3 |

|

180*1200 |

18.5 |

2.9*1.5*1.2 |

11 |

380 |

12.7mm*12 |

60~70m/hour |

3.3 |

|

200*1200 |

number 22 |

3.7*1.5*1.5 |

10 |

380 |

12.7mm*10 |

65~70m/h |

5.3 |

|

250*1200 |

33 |

3.7*1.7*1.5 |

8 |

380 |

12.7mm*10 |

60~65m/hour |

6.2 |

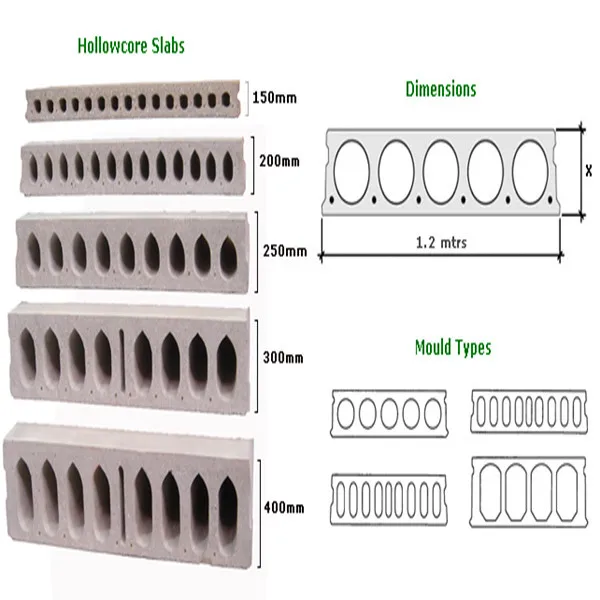

Loads and spans for precast prestressed concrete slabs-

|

Slab size (thickness×width)(mm) |

maximum. Length (m) |

maximum. Load (Kn/m2) |

diameter. Steel load at maximum (mm) |

Maximum steel quantity loaded |

Number of holes |

|

100x600 |

5.1 |

8.11 |

Φ7 |

5 |

6 |

|

120x600 |

6.0 |

8.86 |

Φ7 |

6 |

5 |

|

150x600 |

7.5 |

10.24 |

Φ9.5 |

5 |

4 |

|

180x600 |

9.0 |

16.16 |

Φ12.7 |

4 |

3 |

|

100x900 |

5.1 |

9.76 |

Φ7 |

10 |

10 |

|

120x900 |

6.0 |

8.86 |

Φ7 |

9 |

8 |

|

150x900 |

7.5 |

10.24 |

Φ9.5 |

10 |

6 |

|

180x900 |

9.0 |

16.16 |

Φ12.7 |

9 |

5 |

|

200x900 |

10.2 |

13.22 |

Φ12.7 |

7 |

6 |

|

250x900 |

12.6 |

11.10 |

Φ12.7 |

7 |

6 |

|

300x900 |

15 |

10.83 |

Φ12.7 |

8 |

5 |

1.Wear-resistant alloy

2. High-cost high-strength high-quality steel plate

3. The best vibrator and reducer

4. Professional welding workers

our service:

Our customers are all over the world, such as Egypt, Malaysia, Dubai, Uzbekistan, Myanmar, etc. We not only provide high-quality products, but also provide the best after-sales service.

1. Pre-sales service for concrete hollow slabs

--- Understand customer needs and recommend the most suitable products for you

---Provide technical services to customers before installation

2. Concrete hollow slab sale service

---Supervise the whole production process to ensure that customers receive our products on time

---Provide necessary technical details to customers

-

Concrete wall fence panels/precast concrete fence moulds/hollow cement slab wall precast parts for sale

-

Double Layer Roll Forming Machine Roll Forming Machine Metal Roof Corrugated Steel Sheet Wall Panel Tile Making Machine

-

Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

-

precast concrete formwork/precast concrete stairs

-

Concrete Precast House Precast House Precast Concrete Fence Mold Plastic EPS Hollow Panel Sandwich Panel Machine

-

Prestressed concrete T-beam machine

-

Concrete Wall Panel Making Machine Light Weight Precast Wall Panel Machine for Concrete Panels

-

Sheet Manufacturing Machinery Embossing Machine Products 2020 Automatic Flooring Building Materials Embossing Metal New

-

precast compound concrete hollow core wall panel making machine

-

Drywall gypsum panel/board production line

Other Products

-

$12000.00 / set

$12000.00 / set -

$3900.00 / set

$3900.00 / set