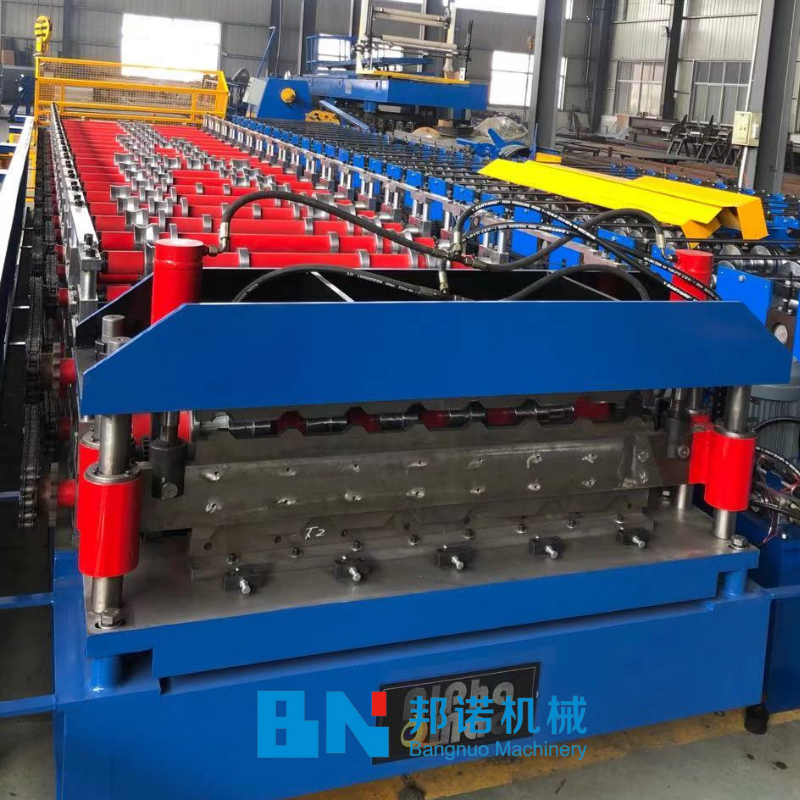

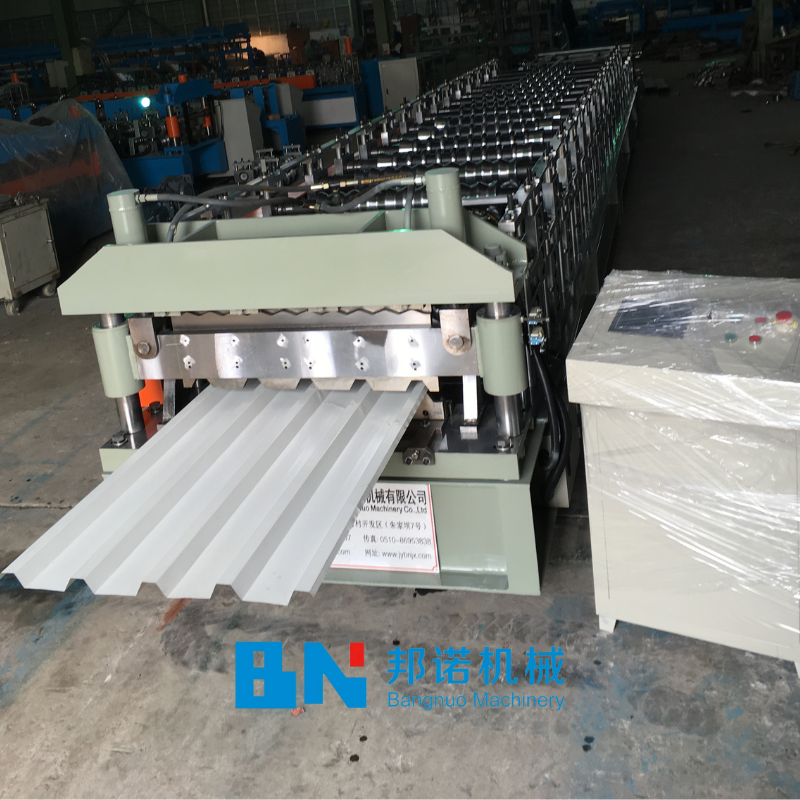

Double Layer Roll Forming Machine Roll Forming Machine Metal Roof Corrugated Steel Sheet Wall Panel Tile Making Machine

-

Supplier: Jiangyin Bangnuo Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms bn bn -

Price: $32000.00 / 1 - 1 sets

$28000.00 / 2 - 2 sets

$25000.00 / >=3 sets -

Min. Order: 1 set

Product details

| port: | Shanghai Port | weight: | 6000 kg |

| Machine Features: | long lasting | raw material: | cement |

| Mechanical test report: | not available | Automatic level: | automatic |

| Showroom location: | not any | strength: | 45KW |

| Video shipment inspection: | if | Production capacity: | 10-15m/min |

| Applicable industries: | Building material stores, manufacturing plants, construction projects | Dimensions (L*W*H): | 18m*2.2m*1.5m |

| Core component warranty: | 1 year | Voltage: | 380V |

| Main process: | forming | Package preview: | |

| type: | fully automated | Marketing Type: | normal product |

| Warranty: | 1 year | Certification: | International Organization for Standardization |

| After-sales service provided: | Overseas service | Core components: | Programmable Controllers |

| payment terms: | L/C, D/P, T/T | Supply capacity: | 1 set per month |

| Packaging Details: | Roll Forming Machine: Plastic film, then loaded into containers. | Main selling points: | high security level |

| capacity: | 0-15m/min | Material: | high strength steel |

| Name: | Roll Forming Machine | brand: | Bonno |

| application: | Building materials machinery | Origin: | Jiangsu, China |

| color: | our decision | Health status: | new |

| feature: | easy to use |

Product Description

describe | illustrate |

Speed of work | 10-15 m/min (excluding shear time) |

Press plate thickness | 0.3-1mm |

control method | Siemens PLC |

Out rack | 5T Electric Unloading Rack |

Number of molding passes | 22 lanes |

Coil | The surface of 45# steel is chrome-plated after finishing. |

Shaft material and diameter Shaft material and shaft diameter | 45# steel finish machining, shaft diameter ¢70mm |

monitor rate | 7.5kw |

Hydraulic station power | 3 kW |

hydraulic | 12Mpa |

scissors material | Cr12Mov, quenched HRC 58-62℃ |

Length Tolerance | 3m±1.5mm |

Voltage | 380V, 50HZ, 3 phases (can be adjusted according to customer requirements) |

transfer method | 1.0 inch single row chain |

Device form | Guide pillar structure |

device color | company colors |

Equipment size | Length*width*height—10.5m*1.8m*1.0m |

delivery date | 80 days |

payment method | 30% prepayment, 70% cash on delivery |

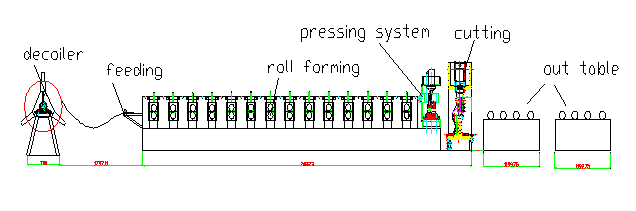

flow chart

equipment composition

5T Electric Unloading Rack | 1 set |

Forming Machine | 1 set |

post-shear structure | 1 set |

Control cabinet | 1 set |

Hydraulic station | 1 set |

discharge meter | 2 sets |

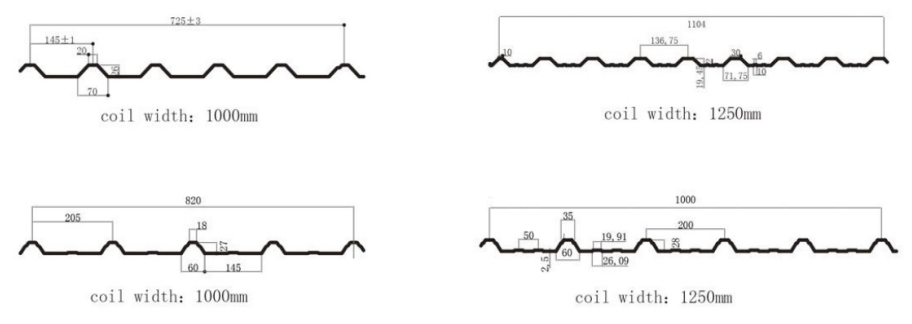

detailed drawing

VIEW MORE

You may like

-

Concrete wall fence panels/precast concrete fence moulds/hollow cement slab wall precast parts for sale

-

Prefabricated hollow panel/sandwich panel production line/prefabricated concrete mold for prefabricated board room

-

Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

-

precast concrete formwork/precast concrete stairs

-

Concrete Precast House Precast House Precast Concrete Fence Mold Plastic EPS Hollow Panel Sandwich Panel Machine

-

Prestressed concrete T-beam machine

-

Concrete Wall Panel Making Machine Light Weight Precast Wall Panel Machine for Concrete Panels

-

Sheet Manufacturing Machinery Embossing Machine Products 2020 Automatic Flooring Building Materials Embossing Metal New

-

precast compound concrete hollow core wall panel making machine

-

Drywall gypsum panel/board production line

Related Search

type double layer roll forming machine

double lay roll forming machine

double covers roll forming machine

double layer roof roll forming machinery

double layer terrazzo tile making machine

corrugated steel tile roof panel forming machine suppliers

colored steel sheet roll forming plant

doubl column vertic lathe machin price

doubl stitch mini sew machin suppliers

automatic high speed double stroke cold heading machine