Drywall gypsum panel/board production line

-

Supplier: Longkou Unity Machinery Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Mr Eason Cheng -

Price: $950000.00 /set -

Min. Order: 1 set

Product details

| Application: | Building; | Warranty: | 1 Year; |

| Advantages: | high efficent; | Supply Ability: | 1000 Sets per Year; |

| Place of Origin: | Shandong, China; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| Type: | Ful-automation; | Condition: | New; |

| Port: | Qingdao; | Materials: | Stainless steel; |

| Warranty of core components: | 1 Year; | Thickness: | 8-25mm; |

| Video outgoing-inspection: | Provided; | Weight: | 16000 kg; |

| Key Selling Points: | Automatic; | Packaging Detail: | exporting standarded; |

| Applicable Industries: | Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Construction works ; | Power: | 500kw; |

| Installation: | guide by our engineer; | Machinery Test Report: | Provided; |

| Voltage: | 380V/50HZ; | Board length: | 1.8m-3.6m; |

| Name: | Paper faced plaster board production line; | Fuel: | coal; diesel; natural gas; heavy oil; |

| Automatic Grade: | Automatic; | Showroom Location: | United States,France,Germany,Russia,Spain,Kenya,Argentina,UAE,Colombia,Romania; |

| Marketing Type: | Hot Product 2022; | Density: | 0.95-1.20g/cm; |

| Size: | 2440*1220mm(adjustable); | Core Components: | PLC,Engine,Pressure vessel; |

| Production Capacity: | 5 million-30 million m2; |

Product Description

Drywall gypsum panel/board production line

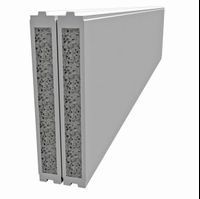

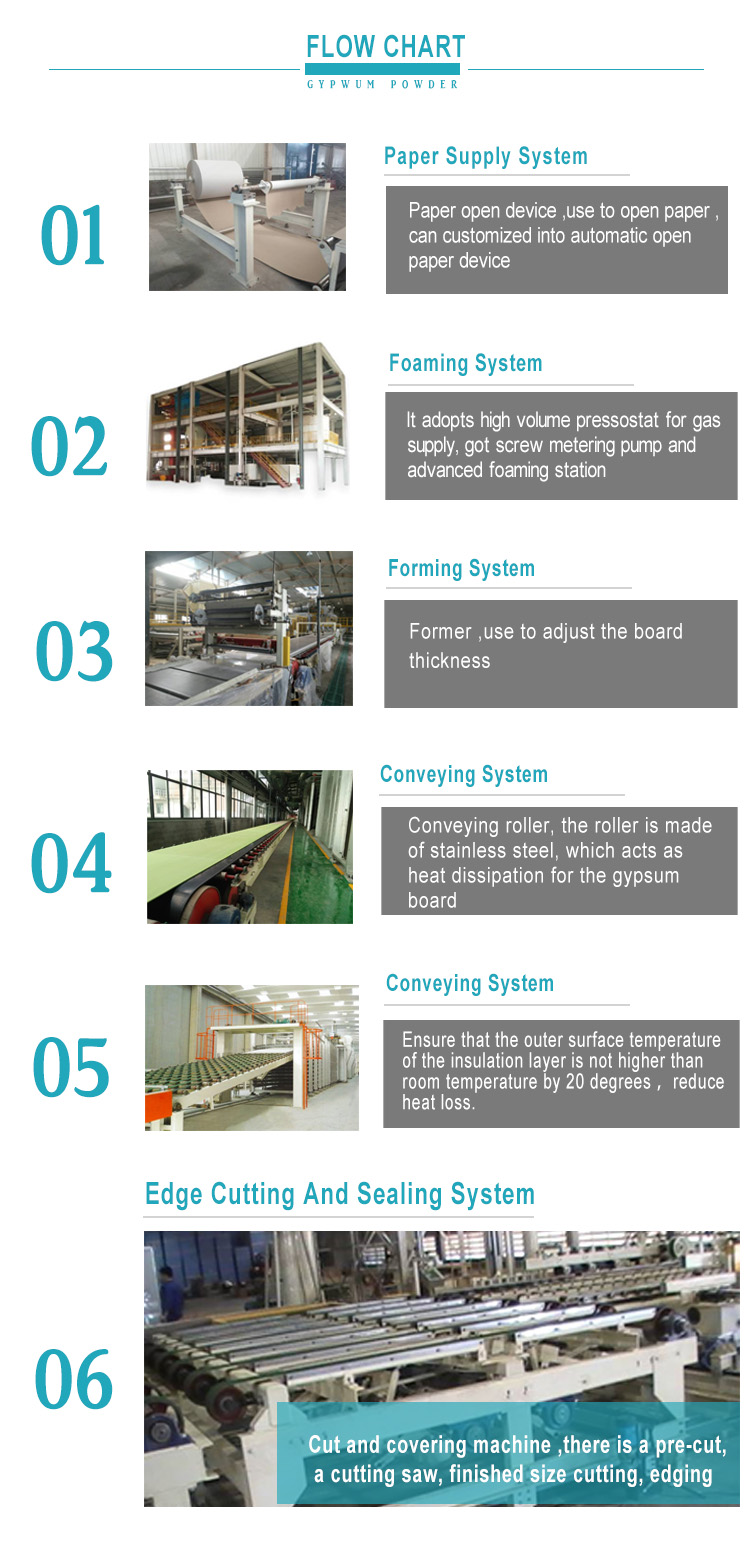

Gypsum drywall panel/ board production line is a kind of light weight board decorating material with many specifications, whose main raw materials are calcined gypsum(natural gypsum, desulfurized gypsum, Phosphor gypsum)and card board( face paper), adding certain percentage of water, starch additives and foaming agent, after mixing, forming, cutting, drying, shearing and sealing procedures etc.

It got the features as light weight fire-proof, heat insulation, vibration-proof. simple to produce, easy of application, elegant decoration effect etc.

It got the features as light weight fire-proof, heat insulation, vibration-proof. simple to produce, easy of application, elegant decoration effect etc.

Product parameter

Gypsum board production line | ||||||||||||

Annual production(m2) | Plant area(m2) | Drying method | Total installed capacity | Productin linespeed | Requird workers | Electrical configuration | ||||||

(m/min) | ||||||||||||

| 1.5 million | 60m×26m | Thermal oil | 116kw | 3 | 8 | Siemens | ||||||

2million | 70m×26m | Thermal oil | 127kw | 4.2 | 10 | Siemens | ||||||

| 3million | 84m×30m | Thermal oil | 166kw | 6.25 | 11 | Siemens | ||||||

4million | 110m×30m | Thermaloil/Hot stove | 210kw | 8 | 11 | Siemens | ||||||

5million | 112m×30m | Thermaloil/Hot stove | 234kw | 10.5 | 11 | Siemens | ||||||

6million | 122m×30m | Thermaloil/Hot stove | 240kw | 12.5 | 11 | Siemens | ||||||

8million | 136m×30m | Thermaloil/Hot stove | 349kw | 16.5 | 11 | Siemens | ||||||

10million | 150m×30m | Thermaloil/Hot stove | 467kw | 20 | 12 | Siemens | ||||||

12million | 172m×30m | Thermaloil/Hot stove | 488kw | 24 | 13 | Siemens | ||||||

15million | 204m×36m | Thermaloil/Hot stove | 578kw | 31 | 15 | Siemens | ||||||

20million | 240m×40m | Thermaloil/Hot stove | 778kw | 40 | 15 | Siemens | ||||||

Product specifications: length 2400—3000mm width 1200—1220mm thickness 8—15mm | ||||||||||||

Detaled information

Our Service

FAQ

Q.How can we guarantee quality?

Always pre-production sample before machine delivery;

Always final Inspection before shipment;

Clients are welcome to come to see the machine trail before delivery;

Q.Why should you buy from us not from other suppliers?

We are leading and professional manufacturer of gypsum board making machine,Our machines have exported to India, Bangladesh, Surname, USA, Argentina Malaysia and other 15 countries.

Q.How long does it take to deliver the machine?

Within 60 days after receiving 50% deposit;

Q.What is the machinery warranty?

12 months warranty for core unit and electric appliances;

Q.What is the after sale service?

(1) provide full formula of making gypsum board products;

(2)Basic machinery operation training;

(3)Machinery maintenance training;

(4) Technical support;

Q:How about your installation&commissioning?

we will assign 2-8 engineers to install and debug the production line, the detailed quantity of engineers will be the degree of automation of the production line

Q:How about the training?

The training is free of charge , and our engineer will be on duty to train your worker.

Why Choose Us

VIEW MORE

You may like

-

Concrete wall fence panels/precast concrete fence moulds/hollow cement slab wall precast parts for sale

-

Prefabricated hollow panel/sandwich panel production line/prefabricated concrete mold for prefabricated board room

-

Double Layer Roll Forming Machine Roll Forming Machine Metal Roof Corrugated Steel Sheet Wall Panel Tile Making Machine

-

Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

-

precast concrete formwork/precast concrete stairs

-

Concrete Precast House Precast House Precast Concrete Fence Mold Plastic EPS Hollow Panel Sandwich Panel Machine

-

Prestressed concrete T-beam machine

-

Concrete Wall Panel Making Machine Light Weight Precast Wall Panel Machine for Concrete Panels

-

Sheet Manufacturing Machinery Embossing Machine Products 2020 Automatic Flooring Building Materials Embossing Metal New

-

precast compound concrete hollow core wall panel making machine

Other Products

-

$25000.00 - $33000.00 / set

$25000.00 - $33000.00 / set

Related Search

decorative gypsum plaster board production line

gypsum board production line overseas installation

sale gypsum board production line

china gypsum board production line

mineral wool board production line suppliers

gypsum board paper production line

export gypsum production line

drywall manufacturing production line

drywall production line

gypsum production line