oil mould thermolator heating oil heating injection mold tem

-

Supplier: Zhangjiagang Wolter Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Sophia Grace -

Price: $662.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Free spare parts; | Condition: | New; |

| Air-switch: | Janpan MITSUBI; | Brand Name: | WOLTER; |

| Color: | Blue; | Name: | oil mould thermolator heating; |

| Packaging Detail: | (oil mould thermolator heating) Packaging Details: export wooden packaging Packing size : 570*252*620mm Packing weight: 79kg Delivery Detail: Shipped in 15 days after payment.; | Cooling method: | Indirect; |

| Place of Origin: | Jiangsu China (Mainland); | Warranty: | 1 Year; |

| Pump brand: | Taiwan Aukland brand; | Cooling tube: | copper, coil cooling; |

| Payment Terms: | T/T; | Weight: | 59KG; |

| Supply Ability: | 500 Set/Sets per Month; | Electronics: | Schneider; |

| Heating tube: | coil heating, more than 6 meters; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Temperature Range: | 60~200℃; | Temperature Control Accuracy: | ±0.5℃; |

| Internal Piping Size: | 3/8"(2x2); | Dimension(L*W*H): | 550*232*600mm; |

| Power(W): | 9KW; | Port: | shanghai; |

| Type: | Oil Temperature Machine; | Application: | Plastic Molding Auxiliary; |

| Controller: | P.I.D multi-stage; | Certification: | CE; |

| Voltage: | Customized; |

Brief Description

mold temperature controller

1. Manufacture

2. Latest Japanese technology

3. Quality warranty

4. Easy operate

5. Different models

Series of Mold Temp Controller

Standard water temperature controller (Max. 100℃)

Standard oil temperature controller (Max. 200℃)

High temp water temperature controller (Max. 160℃)

High temp oil temperature controler (Max. 300/350 ℃)

Two in one mold temperature controller

Three in one mould temperature controller

Other series of WOLTER products

Hot Air Hopper Dryer

Honeycomb dehumidifier

All-in-one dehumidifying dryer

Pet crystallization dryer

Europeanized hopper dryer

Automatic vacuum hopper loader

Water chillers

Plastic crusher / shredder

Color mixer

Application:

(excellent quality and reasonable price mold controller temperature)

WM-O series oil type mold temperature controller have both the standard and high temperature models, which are used to heat up the mould and maintain temperature, although they can be used in other similar applications. High temperature oil from the mould is returned to the cooling tank and cooled by indirect cooling. It is then pressurised by the high-pressure pump, sent to the heating tank and finally to the mould with a constant temperature. With our optimised design, it can reach maximum of 200℃ and the WOLTER temperature controller can maintain an accuracy of ±0.5℃.

Application area

Reaction kettles, extrusion forming equipment, rubber forming machinery, cast film production lines, cable extrusion production lines, the dies for precise plastic molding, the dies for the compression casting of magnesium/aluminum/zinc alloy, roller pressing applied in rubber/plastic and leather industries, crude oil heating of the oil sinks on tankships, paper making industry, bottle blowing, and so on.

Specifications - Standard Water Type

Specifications - Standard Oil type

Features of WOLTER mold temperature controller:

Relative to the oil temperature control system, the use of water as the media has its advantages: high heat transfer efficiency, less pollution, easy access to water resources, but the temperature range is small, up to only 98 ℃.

Developed by WOLTER ultra-boiling water mold temperature controller, the temperature range has reached 120 ℃ ~ 180 ℃ and temperature control accuracy of ± 0.1 ℃ make the use of water type temperature machine with a broader space.

Using oil as heat transfer medium, indirect cooling method achieves heat exchanging, with the characteristics of large temperature operation range and good heat stability. For standard model WM-M series, the heating temperature can reach 200℃, while for high-temp model WM-OH series, it can reach 300℃/350℃.

Both water type and oil type have standard and high temperature models.

1. The electric control box and work-cabinet isolated, good heat insulation, lengthen the service life of electrical appliances.

2. Temperature controller using Japan imported microcomputer P.I.D control, tautomatic calculation that accurate and reliable, saving more than 35%.

3. Safety and fault indication system is perfect, easy maintenance without professionals.

4. Import and advanced components, make sure long service life.

5. Unique coiling type heating, heating and cooling fast, make sure high performance and energy-saving.

6. Internal piping all for seamless stainless steel a integrated, loss is small.

7. Boot automatically exhaust.

6 protection system and indication:

1. Motor-reversal protection with alarm indicator

2. Lack of oil protection with alarm indicator

3. Pump overload protection with alarm indicator

4. By-pass pressure release circuit

5. Phase-failure protection with alarm indicator

6. Abnormal alarm with indicator light

Advantages of WOLTER mold temperature controller:

1. Skillfull technician from Mastui ensure no occurring of water or oil leakage.

2. High quality spare parts adopted. (Schneider electronics, Aulank pump, Kanglong control pannel)

3. Heater -- coiling style, the length is more than 6 meters, ensure fast heating.

Cooling pipe -- material is copper and coiling cooling, ensure fast cooling.

Heating tank -- the capasity is twice bigger than ordinary, excellent thermal insulation and energy saving.

Please be known that, the ability of rapid cooling and heating is so important that is able to ensure the constant temperature thereby improve the passing rate of production.

Shneider electric applicance, Mitsubishi air switch, Aulank pump, punp control pannel.

Bigger and more efficient heating tank

Products show

3 in 1 mold temperature controller

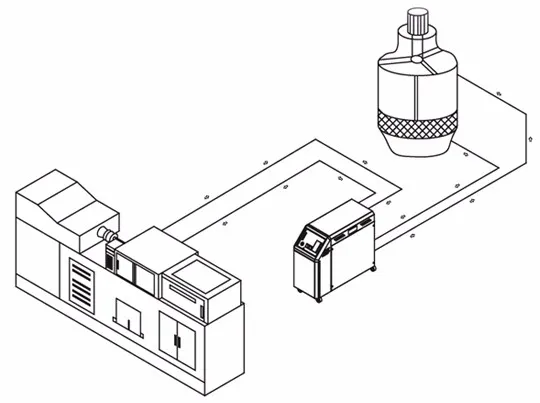

Working Principle

High temperature water returns to the machine and then be pressured by pump to the heaters. After being heated, water (oil) will be forced to mould and continue the circle. In the process, if the water (oil) temperature is too high, the system will activate the solenoid valve to let cooling water cool down the temperature directly (indirectly) until the temperature is down to the system requirement. If the temperature keeps increasing and reach to the set point , system will sound high pressure alarm and stop operation; when system pressure is too high (reach set value of high pressure switch), alarm would sounds and machine halts; if high pressure switch fails to function and system pressure continues to rise to reach set value of safety valve, safety valve would start up to release pressure; when cooling water pressure fails to reach the set value, pressure switch will send a signal of water storage to launch low pressure alarm and machine halts.

Connection diagram

FAQ

Q1: Are you trading company or manufacturer?

A: We are factory which has over 15 years' manufacturing experience and 80% engineer work have more than 10 years.

Q2: How long is your delivery time?

A: 5 - 20 days after order confirmed. Based on the item and quantity.

Q3: What's the MOQ?

A: 1 set.

Q4: What is your terms of payment?

A: If amount ≤ 1000 USD, 100% in advance, if amount ≥ 1000 USD, T/T 30% as deposit, and 70% balance before shipping. We'll show you the photos of the products and package.

Q5: Where's your general loading port?

A: Shanghai port and Zhangjiagang Port

Q6: Can you do OEM?

A: Yes, we can do OEM.

Q7: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q8: How to deal with the faulty?

A: First, our products are produced in strict quality control system, but if any faulty, we'll send new spare parts for free in one warranty year.

Secondly, our technician will periodically follow up customer to help to do maintenance and ensure equipment operation 7/24 be guaranteed.

Q9: How can get the shipping cost?

A: You tell us your destination port or delivery address, we check with Freight Forwarder for your reference.

-

6kw-48kw extrusion molding oil/water heating mold temperature controller

-

Oil Injection Mold Temperature Controller Plastic and Rubber Processing Machinery

-

YUDO controller standard 6 zone best price hot runner temperature controller system model

-

Injection mold temperature controller oil heater

-

Shini STM-910W Industrial Mold Temperature Controller/Plastic Water Mold Heater/Temperature Regulator a eau

-

High gloss multi-function RHCM injection mold temperature control unit

-

HUARE HMC-W rapid heating and high temperature resistant sealed water mold temperature machine 150

-

Yudo Hot Runner LCD Pid 1-24 Digital Zone Temperature Controller Price

-

Hot Runner Heating Oil Mold Temperature Controller For Injection Mold

-

Factory Price Oil Heating Mold Temperature Controller

Other Products

-

$3040.00 / set

$3040.00 / set -

$13430.00 / set

$13430.00 / set -

$3040.00 / set

$3040.00 / set -

$3040.00 / set

$3040.00 / set -

$1.00 / set

$1.00 / set