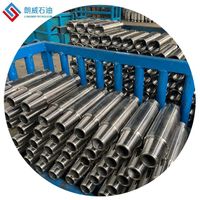

Kingdream 4 5/8 Three Cone Bits For Oil Well Rock Drill Bit Type

-

Supplier: Langfang Uqier Drill Bit Co., Ltd. -

Region: Hebei, China -

Price: $450.00 / 1 - 4 pieces

$285.00 / >=5 pieces -

Min. Order: 1 piece

Product details

| Core components: | Engines, bearings, gearboxes, motors, pressure vessels, gears, pumps | model: | HJ114-637 |

| Applicable industries: | Building materials stores, manufacturing plants, machinery repair shops, construction, energy and mining | Package preview: | |

| Core component warranty: | 4 years | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Marketing Type: | New Products 2020 | After warranty service: | Video technical support, no service, online support, spare parts, on-site maintenance and repair services |

| size: | 3"-26" | Supply capacity: | 20000 pairs per month |

| Local service location: | Canada, United Kingdom, United States, Germany, Pakistan, India, Japan, South Korea, South Africa, Kazakhstan, Ukraine, Uzbekistan, Tajikistan | brand: | kingdream & uqier |

| Mechanical test report: | if | Certification: | CE, ISO, others |

| Showroom location: | Egypt, Canada, United Kingdom, United States, Italy, France, Germany, Saudi Arabia, India, Thailand, South Korea, Algeria, Bangladesh, Kazakhstan, Nigeria, Uzbekistan, Tajikistan, Australia | style: | Insert bit |

| Video shipment inspection: | if | application: | oil and water wells |

| Warranty: | 4 years | place of origin; place of origin: | Hebei china |

Product overview

The steel tooth roller cone bit is mainly used for soft formations, and the toothed roller cone bit can be used for soft to hard formations. At present, the toothed roller cone bit is commonly used. The present invention is also for the toothed roller cone bit. technical improvements. In the past, when the toothed roller bit was used in abrasive sandstone, conglomerate and other formations, the hard alloy teeth with good toughness were not wear-resistant, while the hard alloy teeth with good hardness and wear resistance often had a large number of broken teeth. Short life, slow drilling speed and low cutting efficiency.

List of functions

product specification

Do not | thing | data | ||

1 | strength | 37.5KW | ||

2 | bucket capacity | 2.8 cubic meters | ||

3 | working weight | 125 tons | ||

4 | maximum. traction | 96kN | ||

5 | maximum. Breakthrough | 96kN | ||

6 | tipping load | 60kN | ||

7 | engine capacity | 6750ml | ||

8 | maximum. torque | 500N m |

product configuration

Sales and Service Network

successful project

Thailand project

Indian project

Russian project

VIEW MORE

You may like

-

ironwork mold

-

SG Type Casing Butt Guide

-

Desenders/Cyclone Slurry Separation/TBM and Bored Pile Desander Equipment

-

API Standard Tool Joints Oil Drill Pipe Joints Drill Tool Joint Thread Protector

-

Factory OEM Oil Exploitation Machinery Equipment Parts Piston

-

Rock Roller Bit 9 1/2 Inch IADC537 Insert Drill Bit Factory Price for 244mm TCI Bits

-

Oil Drilling Wellhead Tools API 8C Lift Link

-

coil manufacturers octg

Other Products

-

$550.00 / piece

$550.00 / piece