Full auto metal Gold/Silver/nickel/Zinc/copper/Chrome electr

-

Supplier: Electroplating machine -

Region: Jiangsu, China -

Contact: Ms. Wendy Chan -

Price: $1000.00 /set -

Min. Order: 1 set

| Certification: | CE SGS ISO9001,CE SGS; | Port: | SHANGHAI,SHENZHEN,NINGBO,QINGDAO,GUANGZHOU,TIANJING,DALIAN,TANGSHAN,YINGKOU, QINHUANGDAO; |

| Electroplating machine barrel load: | 0-200KG/barrel; | Electroplating machine application: | metal,plastic,iron,plating,and etc; |

| Electroplating machine barrel bore: | D1-10mm; | Warranty: | 1 Year; |

| Electroplating machine electric unit: | All CE marked; | Electroplating plating available: | Zinc,Copper,Nickel,Tin,brass plating, and etc; |

| Electroplating machine barrel material: | PP, stainless steel; | Power(W): | Customized; |

| Brand Name: | TIAN YI Electroplating machine; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Condition: | New; | Voltage: | 380V/50Hz; |

| Supply Ability: | 10 Set/Sets per Month; | Packaging Detail: | electroplating machine: standard export package: wooden box and carton box. Electroplating machine manufacturer; |

| Dimension(L*W*H): | Cutomized; | Electroplating barrel speed: | 8-20rpm; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Electroplating machine tank material: | PP or stainless steel; |

| Place of Origin: | Jiangsu China (Mainland); | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,50% TT Advance as deposit,30% TT after production approval,20% TT before shipment as balance.; |

| Warranty: | 12Month; | Weight: | 3 tons; |

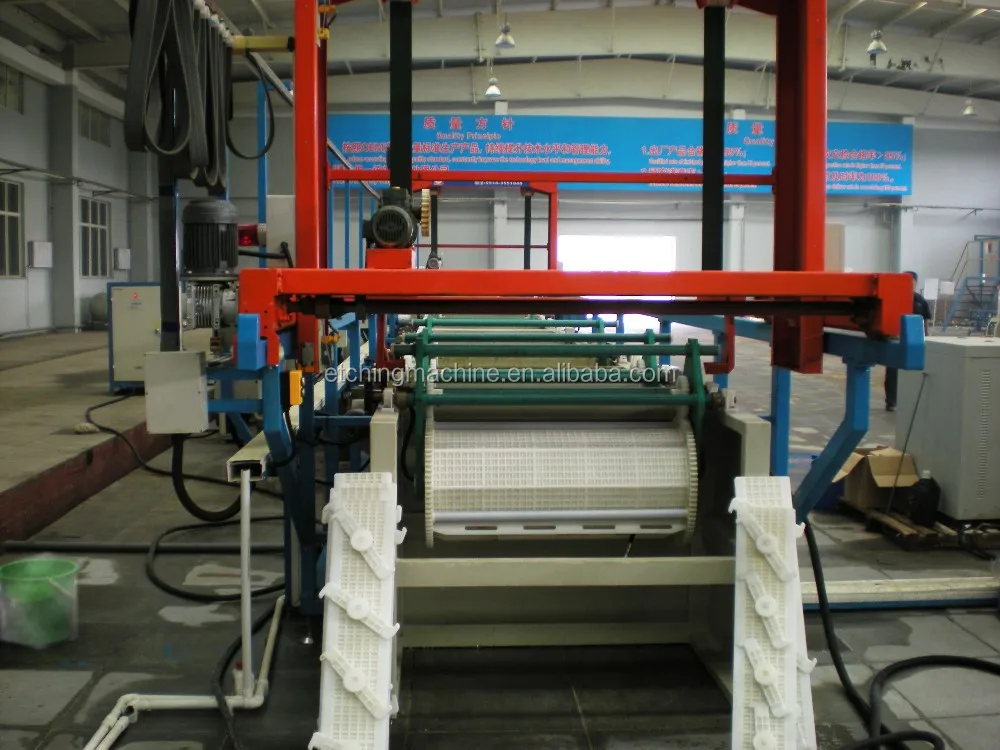

Barrel plating is suitable for electroplating of small parts that cannot be affected or affected by shape, size, etc. It saves labor and improves labor productivity compared with the method of hanging plating or basket plating in early small parts plating. Moreover, the surface quality of the plated parts is greatly improved.

At present, the production of barrel plating accounts for about 50% of the entire electroplating process, and involves dozens of plating types such as galvanizing, copper, nickel, tin, chromium, gold, silver and alloy. Barrel plating has become an electroplating process that is very common in applications and almost in parallel with the plating.

We are speclized in barrel electroplating machine production years, exporting machine to Germany, Sweden, Italy, Belarus, Mexico, Turkey, India, Vietnam, Indonesia, Pakistan and ext all over the world. GOOD QUALITY WITH RESONABLE PRICE.

Warmly welcome your visiting~

YELLOW ZINC PLATING

BULE ZINC PLATING

COLOR ZINC PLATING

Wooden pallet packing

Multi-layer protection to ensure no scratches

All cargo loading by us,Reasonable space arrangement, saving shipping cost

One year guarantee, all inconsumable parts pump/filter/rectifier/kinds motor/chiller and etc, we will guarantee one year, within one year, if any parts broken we will replace it free, natural disaster and human damage is excluded.

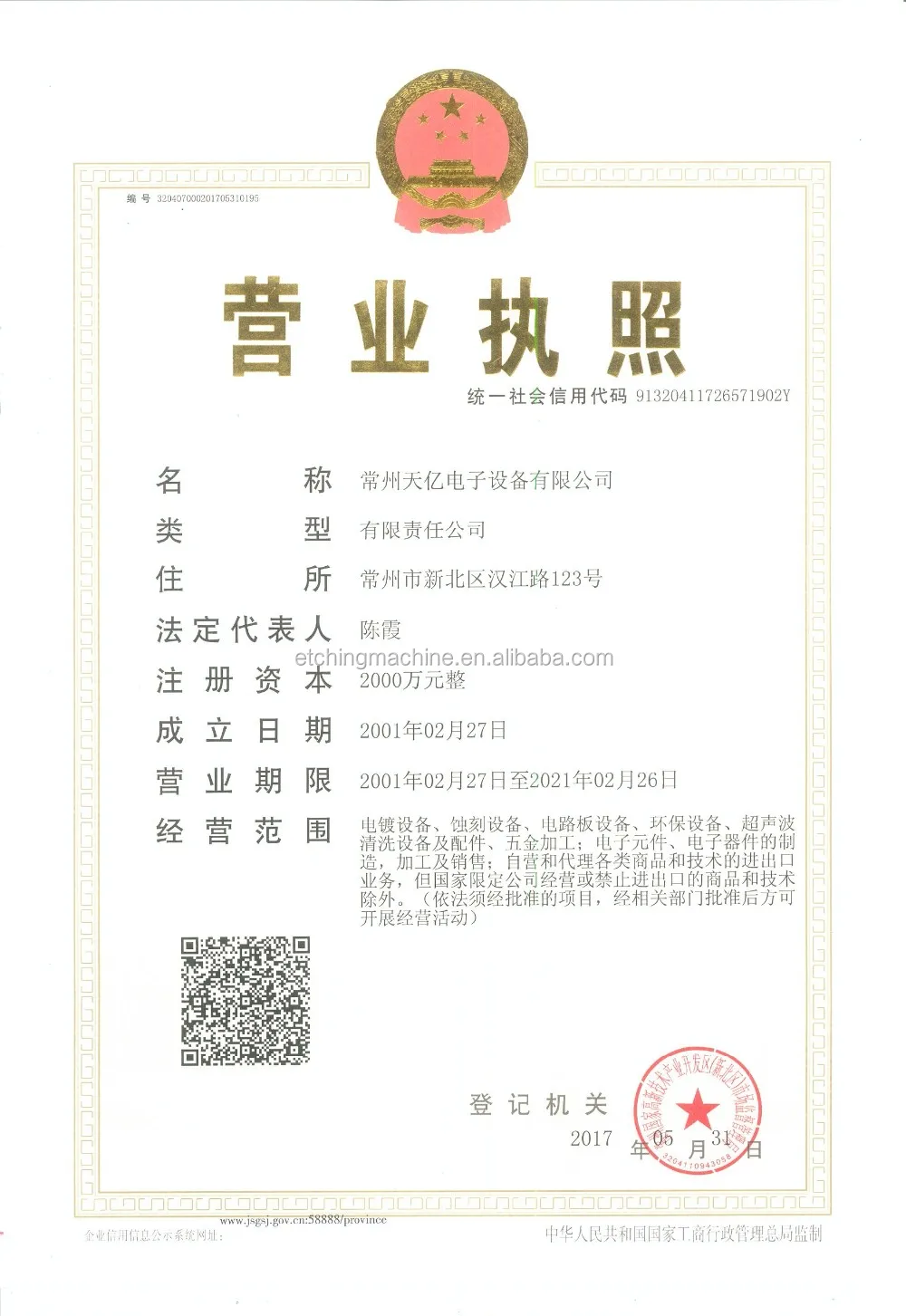

Q2: Why choose us?

1).Over 15 years plating machine manufacturing experience, looking forward for long-term developing and cooperation, good quality guarantee;

2).we have own production team, own plastic engraving machine/CNC laser cuter(just purchase in 2017.12)/welding mahcine and etc, saveing cost for reasonable price quoting;

3).Experience engineer, machine design and production will be good for your practical production.

Q3: Do you provide installation service?

Definitely, we have professional abroad installation team, standard team is one translator, two mechanical engineer, one electric engineer, your local labor team is required to speed up our whole installation and comissioning procedure.

Q4: Where are you located? How to visit us?

Warmly welcome your visiting~

Our address is : No. 123, Hanjiang West Road, Xuejia Town, Changzhou, Jiangsu, China.

If you come directly from Shanghai air port, pls take high speed train from Shanghai Hongqiao station to Changzhou North staion, after one hour you will arrive our city, we wil pick up there.

If you come from other city in China (Like Shenzhen/Guangzhou), pls take a flight to Changzhou Benniu International Airport

Before you come, pls kindly contact me, so that i can guide you better option.

Any inquiry pls directly contact me by wechat/whatsapp: +86-15895086578, or email me(as upon video shown)

-

Hebei Xingxiang steel wire galvanizing machine galvanizing machine

-

Gold Plating Silver Chrome Plating Machine Silver Chrome Plating Machine Rose Gold Chrome Plating Machine

-

Efficient aluminum anodizing and electroplating production line

-

Small electroplating machine

-

Electroplating hard chrome equipment electroplating machine rectifier air-cooled electrolytic electroplating power supply

-

Decolorizer

-

12v 500A Precious Metal Plating Rectifier

-

New Products Feiyide Electroplating Machine Small Bucket Copper Nickel Zinc Electroplating Metal Electroplating Machinery

-

Hannie Plating Equipment Barrel Plating Tank Anodizing Kit Barrel Plating Plant

-

Tongda11 mini electroplating machine Plating Line chrome plating system of small nickel electroplating tank

Other Products

-

$1000.00 / set

$1000.00 / set