Hannie Plating Equipment Barrel Plating Tank Anodizing Kit Barrel Plating Plant

-

Supplier: Liuyang Haney Electromechanical Equipment Co., Ltd. -

Region: Hunan, China -

Contact: Ms Sindy Zhou -

Price: $99.00 /piece -

Min. Order: 1 piece

Product details

| weight: | to see | Health status: | new |

| port: | Guangzhou/Shenzhen | brand: | Haney |

| place of origin; place of origin: | Guangdong, China | Core components: | PLC, pump, tank |

| After Warranty Service: | Video technical support, online support | Tank Material: | Polypropylene PVC |

| Packaging Preview: | Electroplating process: | Chrome Zinc Nickel | |

| Mechanical test report: | if | Certification: | Chief Executive |

| Main selling point: | competitive price | Marketing Type: | New Products 2020 |

| Metal Plating Machinery: | zinc electroplating plant | Electroplating method: | Electroless Plating |

| Packaging Details: | wooden packaging | application: | surface treatment |

| Applicable industries: | Building materials stores, manufacturing plants, construction projects | Function: | cleaning and storage |

| Peripherals: | Rectifier Filtered Anode Chiller | Warranty: | 1 year |

| Video external inspection: | if | Equipment type: | Electroplating line |

| Type of machine: | Electroplating equipment | Voltage: | OEM |

| strength: | OEM | Showroom location: | not any |

| Supply capacity: | 10000 pieces per month | Applicable industries: | plating |

| Dimensions (L*W*H): | OEM | After-sales service provided: | Free spare parts, video technical support, online support |

| Core Components Warranty: | 1 year | Electroplating Plating: | Aluminum Anodizing Technology |

| Local service location: | not any |

Hannie Plating Equipment Barrel Plating Tank Anodizing Kit Barrel Plating Plant

Product Description

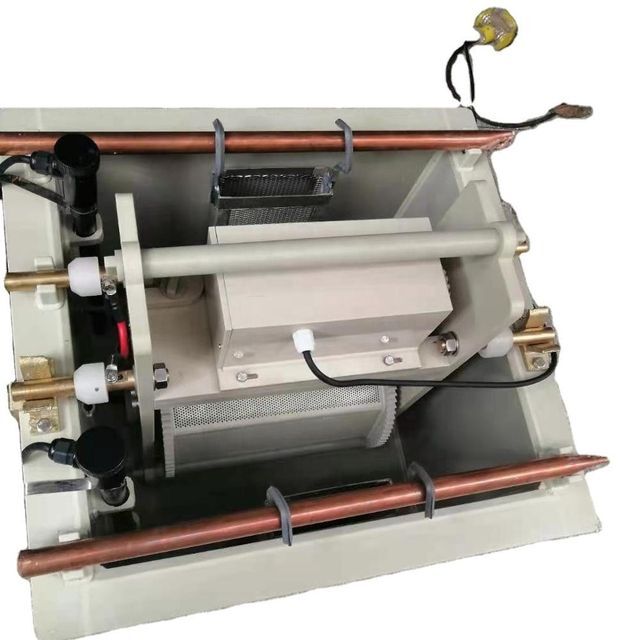

Barrel plating is a form of electroplating used to plate large quantities of smaller metal objects at once. It consists of a non-conductive barrel-shaped cage in which objects are placed before passing through a chemical bath, where they are then electroplated. An important aspect of the barrel plating process is the establishment of bipolar contact between the various components - which results in high plating efficiencies. However, due to the large amount of surface contact between the workpieces, barrel plating is generally not recommended when precise designs or decorative finishes are required. Barrel plating is an efficient and relatively low-cost electroplating method. Parts and assemblies are placed in a slowly rotating bucket while it is immersed in a metal plating solution. Electrical contact is achieved through the use of a hanger or center rod located within the barrel.

describe | Barrel plating equipment | ||||||

size | OEM available | ||||||

Ordering Instructions | Application and size should be informed | ||||||

delivery time | 3 days after order confirmed | ||||||

Product packaging

application

Harney rectifiers are widely used inElectroplating gold, silver, zinc, nickel, copper, chromium, anodizing, electrolysis, electrophoresis, etc.

VIEW MORE

You may like

-

Hebei Xingxiang steel wire galvanizing machine galvanizing machine

-

Gold Plating Silver Chrome Plating Machine Silver Chrome Plating Machine Rose Gold Chrome Plating Machine

-

Efficient aluminum anodizing and electroplating production line

-

Small electroplating machine

-

Electroplating hard chrome equipment electroplating machine rectifier air-cooled electrolytic electroplating power supply

-

Decolorizer

-

12v 500A Precious Metal Plating Rectifier

-

New Products Feiyide Electroplating Machine Small Bucket Copper Nickel Zinc Electroplating Metal Electroplating Machinery

-

Tongda11 mini electroplating machine Plating Line chrome plating system of small nickel electroplating tank

-

HN 4000A CE Electrolysis Nickel Zinc Copper Gold Silver Anodizing Barrel Chrome Plating Equipment Electroplating Machinery

Other Products

-

$50.00 / piece

$50.00 / piece -

$500.00 - $1500.00 / piece

$500.00 - $1500.00 / piece