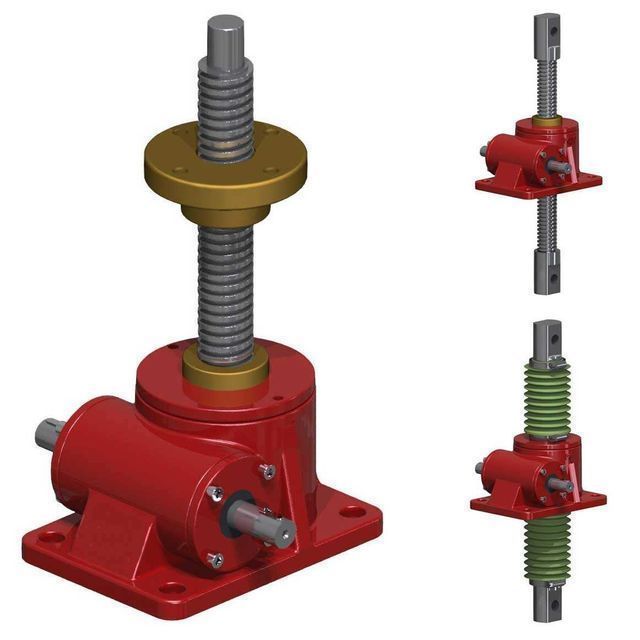

2021 High Quality Worm Gear Screw Jack Load Up To 200 Ton Machine And Ball Screw Jack Actuator

-

Supplier: Dezhou Lude Transmission Equipments Co., Ltd. -

Region: Shandong, China -

Price: $80.00 / 1 - 29 pieces

$75.00 / >=30 pieces -

Min. Order: 1 piece

Product details

| Certification: | GS | Bearings: | SKF, NSK, FAG, etc. |

| Applicable industries: | Hotels, Building Materials Stores, Manufacturing Plants, Mechanical Repair Shops, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Print Shops, Construction, Energy and Mining | Supply capacity: | 2000 sets/month electric screw jack |

| brand: | Luther | place of origin; place of origin: | Shandong China |

| transmission: | insect | Custom Support: | OEM |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Alibaba Trade Assurance | Heat treatment: | Quenching |

| Material: | cast iron or stainless steel | port: | All major ports in China are readily available |

| Installation location: | Foot mount or flange mount | Packaging Preview: | |

| Lubricant: | synthetic grease | application: | Transmission industry |

| Warranty: | 1 year | Enter the form: | Motors, IEC flanges, etc. |

| product name: | Worm Gear Screw Jack | Input speed: | 300-1800 rpm |

| Packaging Details: | 1. Commonly used packaging for screw jacks: PE bag with bubbles, carton re-bubble, the outermost is a plywood box, safe packaging. 2. Or according to customer requirements. | Output speed: | custom made |

| Output form: | Flange output, solid shaft, etc. | Output torque: | 2.6-1195N.M |

| custom made: | accept, no problem |

Product Description

Highest quality worm screw jacks for loads up to 200 tons

Machines and Ball Screw Jack Actuators

feature:

1. Suitable for heavy load, low speed and low frequency; 2. Main components: precision trapezoidal lead screw pair and high-precision worm gear pair; 3. Compact design, small size, light weight, wide driving source, low noise, convenient operation and convenient maintenance . 4. The trapezoidal lead screw has a self-locking function. When the lead screw stops walking, the load can be maintained without a braking device. 5. The lifting height can be adjusted according to customer requirements. 6. Widely used in machinery, metallurgy, construction, hydraulic equipment and other industries. 7. Top end: top plate, clevis end, threaded end, plain end

picture:

Accessories:

Motor coupling connecting rod shaft support bearing

Processing and testing equipment

CNC machining center

Machining centers enable workpiece-specific precision and high-quality finishes. It has maximum material stability, minimum deformation and lifetime accuracy of the product. Machining centers help achieve these improved precisions.

Testing Equipment

Excellence is the cornerstone of Lutheran manufacturing, therefore, strict quality control is carried out at every step of the manufacturing process. Rigorous machine inspections are carried out to ensure the highest standards of operational performance, accuracy and quality.

How to choose the right model?

Some questions can help you make your choice.

Q1: Need a ball screw jack or a lead screw?

Q2: How many kilograms or tons does the screw jack need to lift or lower? Screw shaft length? How fast is the lift? Q3: Which screw top do you need, as shown in the picture above?

Q4: Manual (handwheel drive) or motor drive or both?

Q5: Move the screw (the screw that moves up and down when working) or move the nut? (The nut moves up and down when working), upright or? upside down?

Q6: Do screw jacks need to be linked with two or more sets of screw jacks?

good review

VIEW MORE

You may like

-

Helical gear reducer transmission gearbox for 3D printer SRC helical gearbox reduction motor

-

1400rpm cast iron worm gear reducer, 3kw Nmrv110 worm gear reducer with 100B5 input flange

-

1/2/3/4/5 HP CH/CV Gearbox Motor with Brake Three Phase Reduction AC Gear Motor Price

-

Servo motor precision double lead worm gear reducer

-

High torque low speed horizontal geared motor, 1/2hp 1hp 2hp 3hp single phase motor, AC geared motor

-

RV025 reducer, worm gear reducer

-

MS90L-4 1.5KW high-efficiency mechanical three-phase asynchronous motor

-

Motors with geared motors for conveyors

-

Worm reducer housing drive WP gear worm gear reducer

-

Gearbox 19.05mm bore GX160/ GX200 wet clutch

Other Products

-

$10.00 / piece

$10.00 / piece -

$10.00 / piece

$10.00 / piece

Related Search

worm gear screw jack

electric motor worm gear screw jack

electric worm gear screw jack

lightweight worm gear screw jack

high quality stainless set screws cone point

high quality self_drilling screws

high quality din7982 tapping screws

forging alloy steel worm gear screw shaft

high quality bronze worm gear brass

high quality stainless steel torx security screw