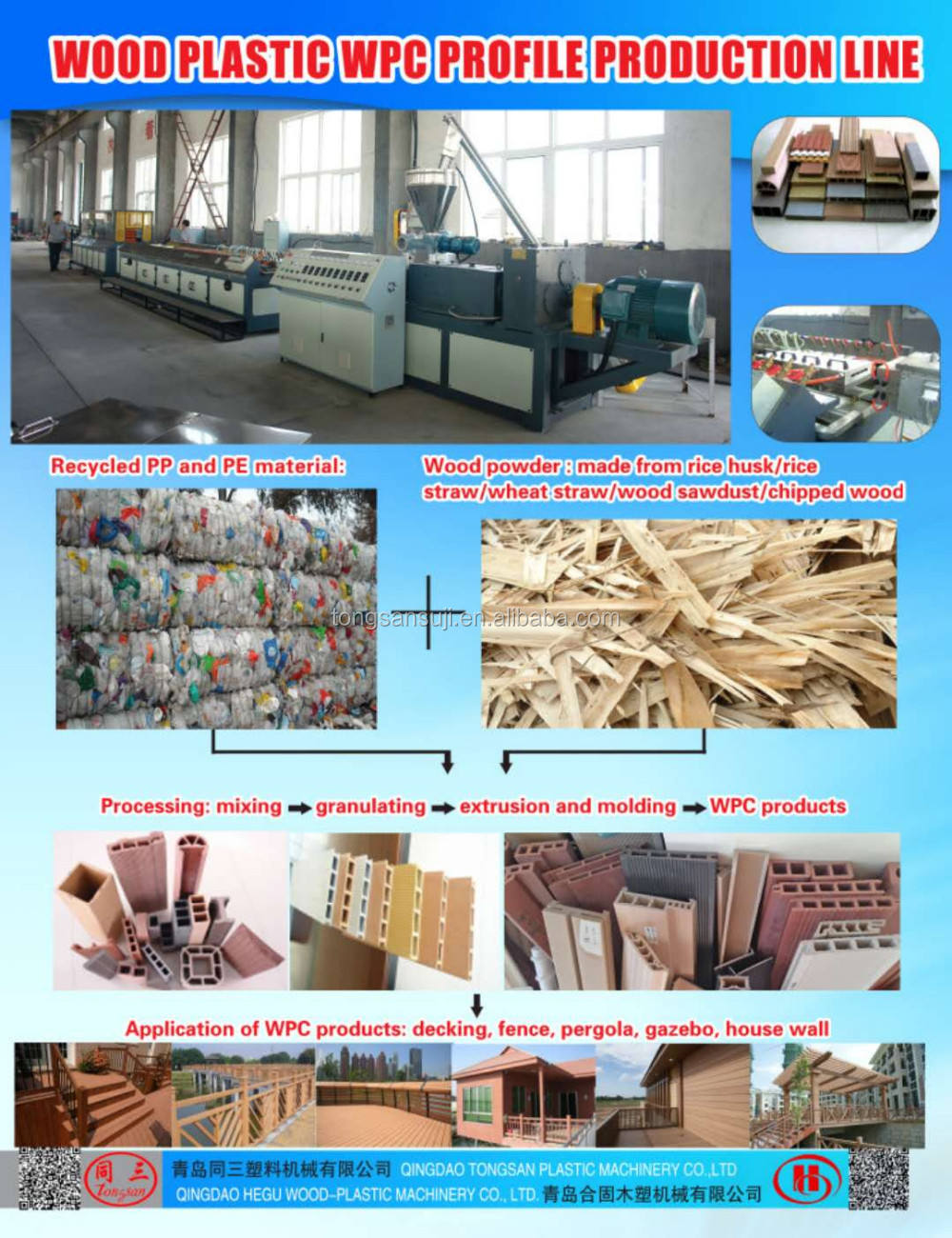

WPC profile extruder for the manufacture of WPC floor and wall panels from recycled PP/PE plastic and wood waste

-

Supplier: Qingdao Tongsan Plastic Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr Gang Li -

Price: $38000.00 / 1 - 4 sets

$37000.00 / 5 - 9 sets

$36000.00 / 10 - 19 sets

$35000.00 / >=20 sets -

Min. Order: 1 set

| Video external inspection: | if | Screw aspect ratio: | 28 |

| brand: | pass three | wood material: | Wood sawdust/rice husk/straw/cotton straw |

| Health status: | new | WPC decoration machine: | wood plastic extruder |

| WPC Profile Machinery: | WPC/WPC | weight: | 2KG |

| place of origin; place of origin: | Shandong China | Core components: | Bearings, Motors, Pumps, Gears, PLCs, Pressure Vessels, Engines, Gearboxes, Screws, Extruders and Dies |

| payment terms: | letter of credit, wire transfer | Main selling point: | Sustainable |

| Screw diameter (mm): | 65 mm | Wood plastic machine: | Wood Plastic Extrusion Line |

| WPC Extrusion Line: | Conical twin screw extruder | Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Stores, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies |

| application: | Plates, profiles, plates | Plastic material: | PE/PP/PVC recycled plastic material |

| Packaging Details: | The WPC wood plastic machine consists of many parts, each part is packed with plastic wrap. Wooden case packing of fragile special parts. The packing list is provided to the customer. Each package should be marked according to customer's requirements | Supply capacity: | 10 sets per month |

| WPC production line: | Decks, fences, siding, gazebos... | Screw Design: | twin screw |

| Mechanical test report: | if | port: | Qingdao Port |

| Screw material: | 38CrMoAIA and bimetals | Screw speed (rpm): | 100 rpm |

| Power (kW): | 37 | Showroom location: | not any |

| Core Components Warranty: | 1 year | Voltage: | 380V 50HZ three-phase (customized) |

| Marketing Type: | Hot Products of 2019 | Plastic Processing: | PE,PP,PVC,WPC,WPC |

| Finished goods: | WPC floors, wall panels, columns, profiles | Dimensions (L*W*H): | 20mx2.5mx2.2m |

| Warranty: | 1 year | Wood plastic machine: | WPC Wallboard Extrusion Line |

| Twin screw type: | Counter-rotating conical twin-screw | Processing: | Mixing, pelletizing, extrusion |

WPC compound machine/WPC floor extrusion line/WPC product manufacturing machine.

WPC is a new type of synthetic material made of PVC, PP, PE resin or recycled plastic and plant fibers (wood flour, chaff, straw, etc.) through mixing, extrusion, shaping, wire drawing and other processes. Close and cut. This wood-plastic material is not only very similar to natural wood in appearance and feel, but also has the same characteristics as wood that can be cut, planed, sawn, unparalleled in grip, low in water absorption, moisture-proof, moth-proof, and mildew-proof. . , acid and alkali resistance, corrosion resistance, with the characteristics of fire. The products are non-toxic, non-polluting, environmentally friendly and energy-saving, and do not contain harmful substances such as formaldehyde, benzene, ammonia, etc. Wood-plastic products are widely used in outdoor floors, hydrophilic buildings, balconies, gardens, chairs and benches, fences, indoor doors and windows, furniture, etc. .

Plastic material | Recycled PP/PE plastic |

wood material | Rice husk/straw, wheat husk/straw, wood sawdust, wood flour from waste wood |

Plastic percentage | 25-30% |

wood flour percentage | 50-70% |

Finished goods | WPC Flooring, WPC Wall Cladding, WPC Pergola Profiles, WPC Fence Profiles and Other WPC Building Profiles |

Production Process | Raw material--mixing--granulation--extrusion--surface treatment |

A mixture of natural wood and plastic fibers forms a wood-plastic composite. These help reduce the overall weight of the vehicle, which in turn improves fuel efficiency. Wood-plastic composites are an inexpensive and environmentally friendly alternative to plastic and steel components in construction applications. Therefore, their demand keeps growing in the market.

The Wood Plastic Composites Market is segmented by Type: Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC) and others. Polyethylene-based wood-plastic composites dominate the industry. The building and building products segment is considered to be the largest consumer of polyethylene and PVC wood-plastic composites. The auto parts sector is close behind, with wood-plastic composites used to make lightweight auto parts

Based on its application, the market has been segmented into building and construction products, trim, fencing, industrial and consumer products, auto parts, and others. Among them, the construction and construction sector has become the largest sector in the global wood-plastic composite material market.

Description of WPC machine/WPC machine/WPC floor machine

1. New product: WPC is a new type of synthetic material that has been mixed, extruded, shaped, demolded and cut.

2. Material: PVC, PP, PE resin or recycled plastic and plant fiber (wood flour, chaff, straw, etc.) are used as raw materials.

3. Advantages: This wood plastic is not only very similar to natural wood in appearance and feel, but also has the same characteristics as wood, can be cut, planed, sawn, unparalleled grip, low water absorption, good moisture resistance, Mosquito proof. , mildew, acid and alkali resistance, corrosion resistance, fire resistance. The product is non-toxic, non-polluting, environmentally friendly and energy-saving, and does not contain harmful substances such as formaldehyde, benzene, and ammonia.

4. Application: Wood-plastic products are widely used in outdoor floors, waterfront buildings, balconies, garden landscapes, chairs and stools, fences, indoor doors and windows, furniture, etc.

Production process of WPC machine/WPC machine/WPC floor machine

1. Prepare materials:

Wood powder material:80-100 mesh wood flour, can be made from wood sawdust, rice husk, straw, wheat husk and straw, cotton straw and agricultural waste. What the machine needs is a wood shredder and a shredder

Plastic material:The recycled PP/PE plastic is washed and shredded into flakes. What the machine needs is a plastic washing and crushing line.

2. Mixed granulation of wood-plastic materials by wood-plastic machine/wood-plastic compound machine/wood-plastic floor machine

mix:Put all materials such as PP/PE recycled chips, wood flour, chemical additives into the mixer

Granulation:It is important to use a high-quality granulator to make WPC granules, and a dehumidification system is required during the granulation process.

3. WPC product extrusion-molding-surface treatment

Extrusion:Our conical twin-screw extruder is specially designed for the extrusion of high-quality wood-plastic products, it can make wood-plastic materials fully mixed and melted evenly, equipped with well-designed molds and calibration, online cutting device, our wood-plastic The WPC profile machine can produce good WPC products, such as decorative profiles, garden profiles, chair profiles, pergola profiles, railing system profiles.

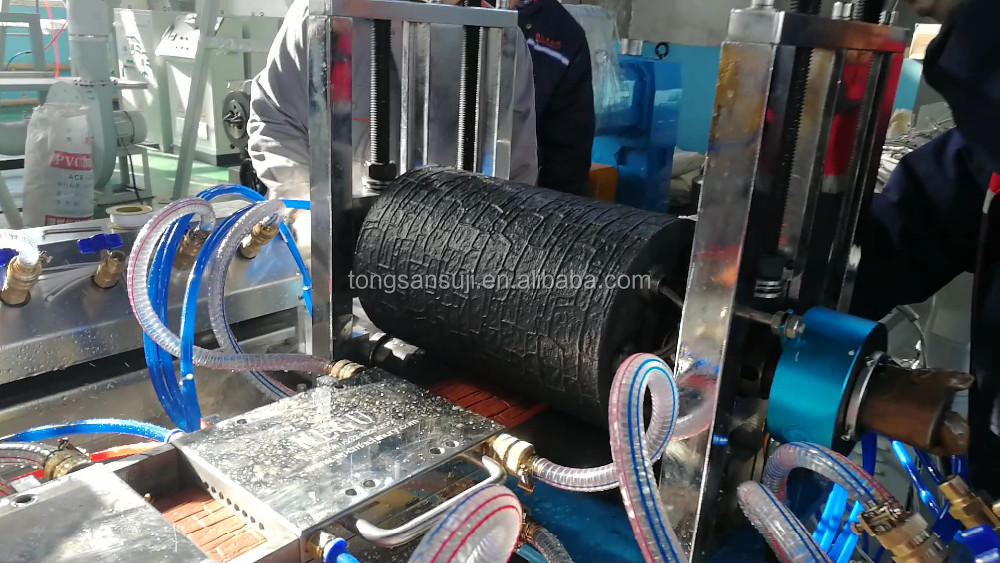

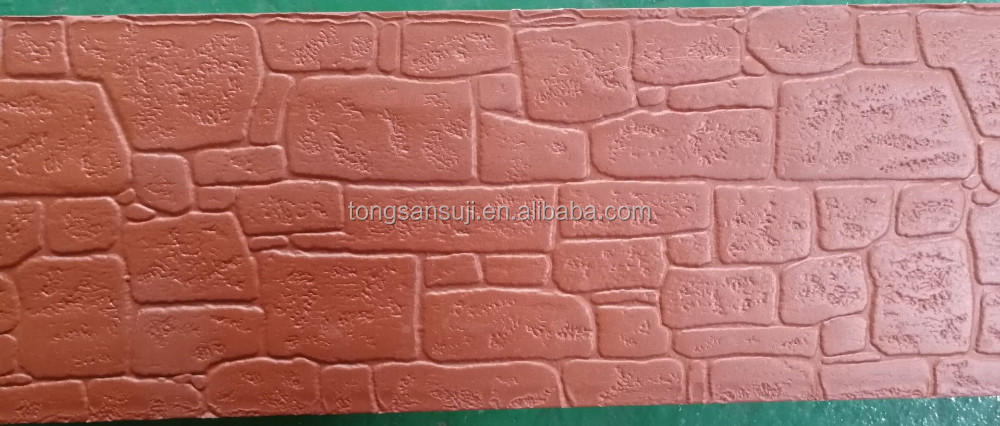

Surface treatment:Sanding, wire drawing and embossing process make wood plastic products have natural wood grain, which is very popular among customers.

Wood Pelletizer

It can do amazing 3D embossed designs

High-quality molds for WPC production, you can change molds to make different WPC products through the same WPC production line.

We provide complete WPC production turnkey projects, and can provide auxiliary equipment such as sanding machines, embossing machines, brushing machines, laminating machines, engraving machines, etc.

The wood powder pulverizer is suitable for sawdust, rice husk, straw, etc., and can make wood fiber into 80-120 mesh wood powder.

If the wood flour has high moisture content, we can also equip you with this wood flour dryer.

If you want to use recycled plastic to make wood plastic products, we can also equip you with plastic washing and crushing recycling machines

If your recycled plastic has high moisture content and low density, we recommend that you have the plastic drying agglomeration unit pictured above

Mixer is necessary for wood plastic production, it can mix wood and plastic and chemicals evenly

If customers like large capacity and automatic mixing system, we can equip with the above automatic batching and mixing system, which can automatically mix 1.6 tons per hour.

-

mini plastic extruder laboratory micro single screw extruder extrusora

-

20~110mm PE pipe production line plastic pipe making machine

-

Custom Elastic Band Making Machine

-

High precision 0.02mm finishing winding 3D filament making machine hot sale in 2020

-

Certified line extruder SJ30/25

-

EPE foam sheet machine/PE foam network pipe extrusion line,Ellie Whats 008613780912769

-

HDPE plastic pipe making machine/plastic water pipe production line/plastic energy pipe making machine

-

PET Plastic Belt Production LinePET Packing Belt Equipment Belt Making Machine

-

Wood Plastic WPC Door Frame Forming Machine Production Line

-

150mm screw pp pe waste plastic recycling extrusion granulation pelletizing machine production line

Other Products

-

Plastic Single Wall PVC PP PE Corrugated Pipe Manufacturing Extruder/Corrugated Plastic Pipe Machine$18000.00 - $20000.00 / set

Plastic Single Wall PVC PP PE Corrugated Pipe Manufacturing Extruder/Corrugated Plastic Pipe Machine$18000.00 - $20000.00 / set