Plastic Single Wall PVC PP PE Corrugated Pipe Manufacturing Extruder/Corrugated Plastic Pipe Machine

-

Supplier: Qingdao Tongsan Plastic Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr Gang Li -

Price: $20000.00 / 1 - 2 sets

$19000.00 / 3 - 4 sets

$18000.00 / >=5 sets -

Min. Order: 1 set

| Certification: | CE, ISO | Video external inspection: | if |

| port: | Qingdao Port | payment terms: | L/C,Western Union,T/T,MoneyGram,Cash |

| After-sales service provided: | Engineers can repair machinery overseas | After Warranty Service: | On-site maintenance and repair services |

| place of origin; place of origin: | Shandong China | type: | Pipe production line |

| application: | Automobile wire, electric wire pipe, circuit... | Phone/whatsapp/viber/WeChat: | 0086-13969891023 |

| Core Components Warranty: | 1 year | Marketing Type: | New Products 2020 |

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Stores, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies | Mechanical test report: | if |

| Pipe diameter: | 4.5-175mm | Production capacity: | 10-80kg/hour |

| strength: | 20-50kW | Supply capacity: | Annual output of 200 sets of PP plastic bellows extruder |

| Main selling point: | easy to operate | cooling method: | Air-cooled and water-cooled |

| Health status: | new, new | weight: | 5000 kg |

| Core components: | PLC, engine, bearing, gearbox, motor | Dimensions (L*W*H): | 10x1.25x1.5m |

| Packaging Details: | PP plastic bellows extruder export standard packaging (also according to customer demand) | Voltage: | 380V according to customer needs, customized |

| Warranty: | 1 year | Showroom location: | Egypt, Turkey, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, Chile, United Arab Emirates, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan |

| brand: | TS PP Plastic Corrugated Pipe Extruder | Pay: | TT, LC |

| Tube: | PP, PE, PVC, PA, PE |

1. Conditions of use: | 380V/3 phase/50HZ |

2. Applicable materials: | Polypropylene, polyethylene, polyvinyl chloride |

3. Pipeline range: | φ9-50mm |

4. Output capability: | 60-80kg/hour |

Production speed | 20-30m/min |

Extruder Model | SJ65 |

main motor power | 22kW |

Machine size | 12m*1m*3m(L*W*H) |

Machine list | quantity |

SJ65/30 single screw extruder with automatic feeding and drying hopper | 1 set |

die | 1 set |

Mould: 72 pieces of mould | According to customer's request |

Wire pay-off insertion device | 1 set |

Forming machine: with water cooling | 1 set |

Coiler, double station | 1 set |

power control system | 1 set |

spare parts | 1 set |

Detailed description of plastic single wall corrugated pipe machine

1. Material of single-wall corrugated pipe and corrugated pipe:

The production line can continuously produce PE, PP, PVC, EVA corrugated pipes, and PA corrugated pipes

2. Application of single-wall corrugated pipe and corrugated pipe:

Plastic single-wall corrugated pipe has the characteristics of high temperature resistance, corrosion resistance, wear resistance, high strength, good flexibility, etc. It is widely used in automobile wires, electric threading pipes, machine tool circuits, protective pipes and other fields. Lighting wires, air conditioning pipes, washing machine pipes, etc.

3. Advantages of single-wall corrugated pipe machine (corrugated pipe machine):

The SJDBGZ series plastic single-wall corrugated pipe production line developed by our company adopts gear transmission module and template to realize water circulation cooling and air cooling of the product, ensuring high-speed molding, uniform corrugation, and smooth inner and outer pipes. These bellows are especially used as wires for luxury cars.

This production line has excellent performance and reasonable price, and is your best choice for producing single-wall corrugated pipes.

1. Single screw extruder for plastic corrugated pipe machine:

2) With drying hopper

2. Corrugated tube forming machine high-speed forming machine

20-30 m/min speed.

with water cooling

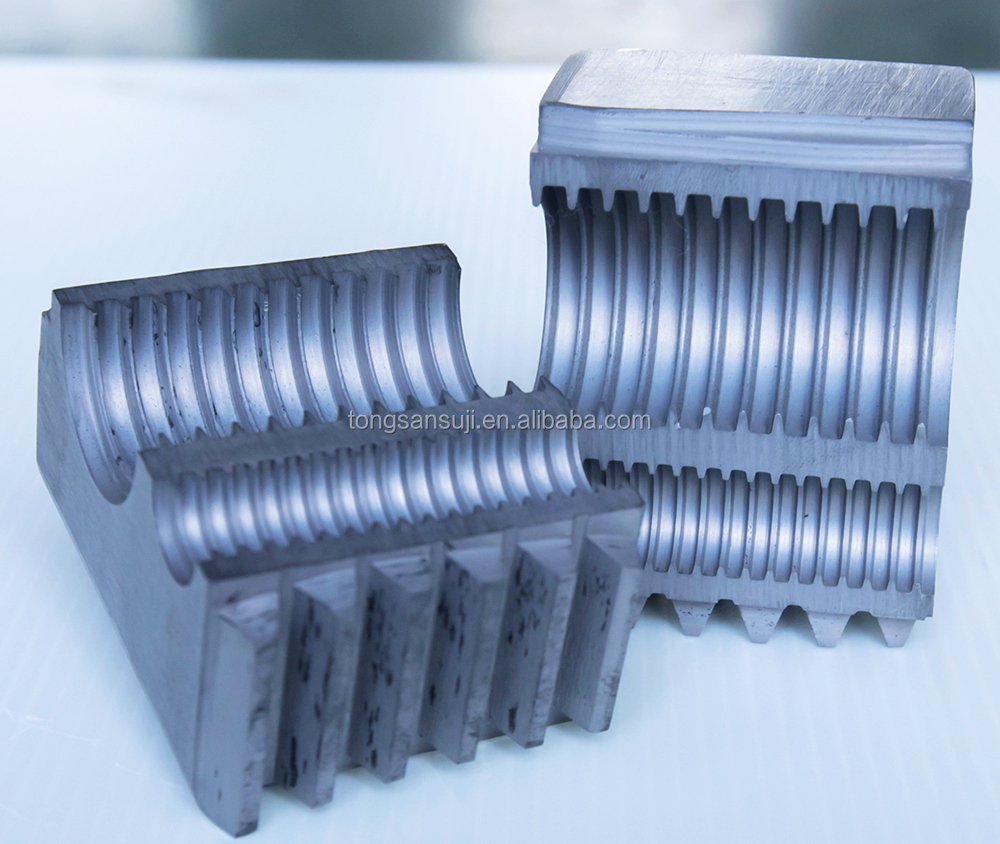

Bellows Machine High Speed Mould

Material: 40 cr with nitrification

Number of molds: 72 pairs

Cavity: double size on the same mold

Speed: 20-30 m/min

Automatic winding machine

1. Winding station: double station

2. Winding method: automatic winding

3. Meter counting: automatic counting

4. Winding rice: customized

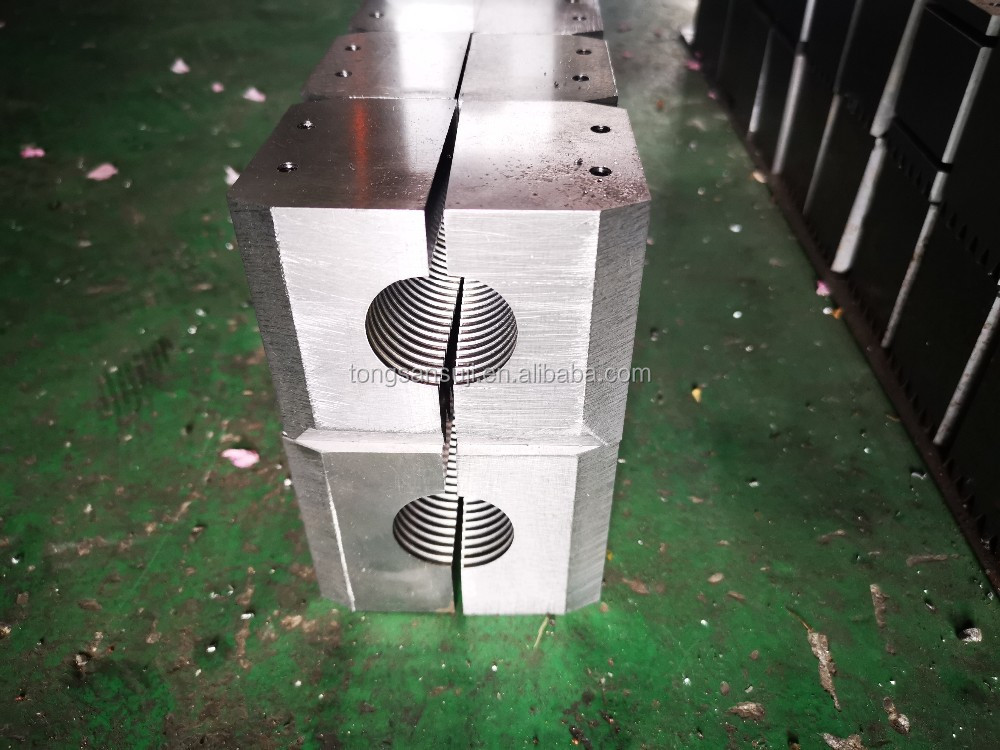

Bellows mold production:

We have our own workshop and CNC machine to make bellows molds by ourselves, and we also have a design team to design bellows molds according to customers' requirements.

Such as magic pipe mold, hookah pipe mold, double size mold...

installment and debugging

We will send technicians to the buyer's factory to install and test the entire production line, and our engineers will train the buyer's workers until they can run our machines for stable production

After-sales service: one year warranty, permanent service!

During the one-year warranty period, we will provide efficient and timely maintenance, and if any spare parts are damaged due to quality problems during the warranty period, we will provide new spare parts for replacement free of charge.

-

Pipe making machine making square pipe machine for sale

-

2023 new shower hose making machine for flexible braiding stainless steel 201 304 brass nuts with pvc mixer insert

-

Pakistan Market 304/201 SS Coil Decoration Square Tube Making Machine Tube Machine

-

Tube Mill Rolls & Materials High Quality Steel Tube Welding Machine Korea Spare Parts Indonesia Supply Saudi Arabia

-

Lower Price Attached Vibratory Cement Batch Concrete Pipe Making Machine Manufacturer

-

Large Metal Conduit Making Machine/Galvanized Steel Conduit Forming Machine/Double Lock Flexible Pipe Making Machine

-

Pipe making machine carbon steel pipe making machine

-

Flexible metal pipe making machine/Flexible metal pipe making machine

-

Pittsburgh lock forming machines, lock forming machines

-

Foshan CS/carbon/stainless steel/iron welded round pipe production line pipe making machinery

Other Products

-

$35000.00 - $38000.00 / set

$35000.00 - $38000.00 / set