Single screw pump eccentric screw pump rubber stator

-

Supplier: Guangdong Standard Fluid Systems Co., Ltd. -

Region: Guangdong, China -

Contact: Ms June Zhang -

Price: $45.00 /piece -

Min. Order: 1 piece

| port: | Foshan, China | Standard or non-standard: | STD |

| Custom Support: | OEM | brand: | Seapac |

| place of origin; place of origin: | Guangdong, China | Supply capacity: | 1000 pieces per month |

| Packaging Preview: | payment terms: | Western Union, wire transfer | |

| Warranty: | 1 year | model: | NM2-12 |

| Packaging Details: | A single carton pack Multiple products are packed in wooden boxes, each box does not exceed 30kg |

Introduction of screw pump stator

1 The stator is a threaded sleeve, and the rotor has more than one threaded head.

2 The stator is one of the main wear parts of the single screw pump. The stator wears due to the solid content, pressure and viscosity of the conveyed medium and the rotation of the rotor.

The wear of the stator surface will cause the rotor and the stator to no longer have a seal, and the stator must be replaced in time.

3 The fit and shape of the stator and rotor are the main performance parameters of the pump.

4 There are many choices of stator materials, there are a variety of natural and synthetic elastic rubber materials, including natural rubber, nitrile rubber, EPDM rubber, FKM, etc., and special materials can also be provided for harsh working conditions

Introduction to the main materials of the stator:

For different media, there are different rubber formulations to choose from, such as wear resistance, corrosion resistance, heat resistance

Rubber material details:

1) One of the most important parts in the screw pump is the stator, and the high quality of the stator is determined by the vulcanization process of the rubber.

2) Strictly control the selection of raw materials, strictly control the mixing process and the final analysis in the laboratory, to ensure the high quality and long service life of the products.

3) In close cooperation with the customer, we define the properties of the material to meet the customer's needs. In addition, based on our long-term injection molding experience, focusing on production safety and cost reduction, we have better performance selection material solutions compared to ordinary products.

Tube:

1) Stator tube options include mild steel and stainless steel,

2) Special materials: 316L, 904L, CD4MCu duplex stainless steel, can work at temperatures up to 150 degrees

Stator materials commonly used by our company:

Rubber: Nitrile; EPDM; FPM; SI

Stator housing: Q235; SUS304; SUS316L

Progressive cavity pumps with different rotor/stator geometries, operating methods and delivery principles

/Geometry belongs to single head screw/rotor. With a circular cross-section, large pitch and large thread depth, the depth changes continuously as the rotor rotates in the stator. The section of the stator is the same as the section of the rotor, but the stator is a double-ended internal thread with a distance of 180°. When the stator and the rotor are meshed together, a 1/2 stator cavity is formed. As the rotor rotates, the continuous forward cavity between the rotor and the stator transports the medium enclosed therein smoothly and continuously from the suction end of the stator to the discharge end.

The flow is determined by the pitch, diameter and eccentricity of the rotor/stator and the speed of the pump.

Outlet pressure depends on series and differential pressure of max 6bar 85psi per stage,

The S-shaped geometry 2-stage progressive cavity pump can achieve 12bar 170psi differential pressure and 100% flow.

The L-shaped geometry single-stage screw pump has the same shape as the S-shaped 2-stage pump, with the same diameter and eccentricity. The L-shaped geometry has twice the rotor/stator pitch than the S-shaped geometry. As a result, the pump can deliver twice the flow compared to the S-shaped geometry with a maximum differential pressure of 6bar 85psi.

Double threaded geometry stator

The double-threaded rotor has an elliptical cross-section, a large pitch and a large thread depth. The rotor is in an eccentric circular rotation in a fixed stator. The stator also has the same geometry as the rotor, but the stator has a three-start thread 120° apart.

When the stator and the rotor are engaged, a 2/3 geometric cavity is formed between them. When the rotor rotates, the continuous forward cavity between the rotor and the stator is smoothly and continuously conveyed from the suction end of the stator to the discharge end. end.

Flow is determined by screw pitch, rotor/stator diameter and eccentricity, and pump speed. Outlet pressure depends on series and maximum differential pressure 6bar 85psi per stage.

The cavity size of the double-start thread geometry is about 75% of that of the S/L type, but the cavity is opened twice per revolution, and the 1/2-level geometry of the cavity is opened only once per revolution.

Therefore, the double-start thread geometry of the rotor/stator provides 50% more flow per revolution than the S/L type,

The double-start thread geometry of the 2-stage screw pump has 150% more flow than the S-geometry single-stage pump, and the maximum differential pressure is 12bar 170psi.

The 1-stage double-start thread geometry and dimensions are the same as the PCP and 2-stage PCP pumps, as are the ellipses and eccentricities. But the pitch is twice the rotor/stator of the double-ended 2-stage shape. Therefore, at a maximum differential pressure of 6bar 85psi, the pump produces a 300% higher flow ratio than the S-shaped geometry

STD Factory Availability

1) ST D's factory has a variety of accessories, we provide quick turnaround to help reduce equipment downtime, you don't need a lot of inventory.

2) Spare parts, which can be shipped quickly, ensuring that production is not interrupted or reduced to a minimum downtime. With good service and very competitive prices, customers can earn time from working with us.

very competitive price

With customers increasingly concerned about operating and maintenance costs, we need to prioritize spare parts prices and availability when evaluating plant savings and efficiency.

Using their engineering knowledge and production capabilities, STD companies are capable of producing spare parts of good quality and competitive prices (spare parts for NETZSCH, SPEEDEX, MONO, VISCOTEC, STD, etc.)

quality assurance

STD is a professional R&D and manufacturer of single screw pumps and accessories. The product quality has been inspected and recognized by customers in the professional market, and won the recognition and praise of customers.

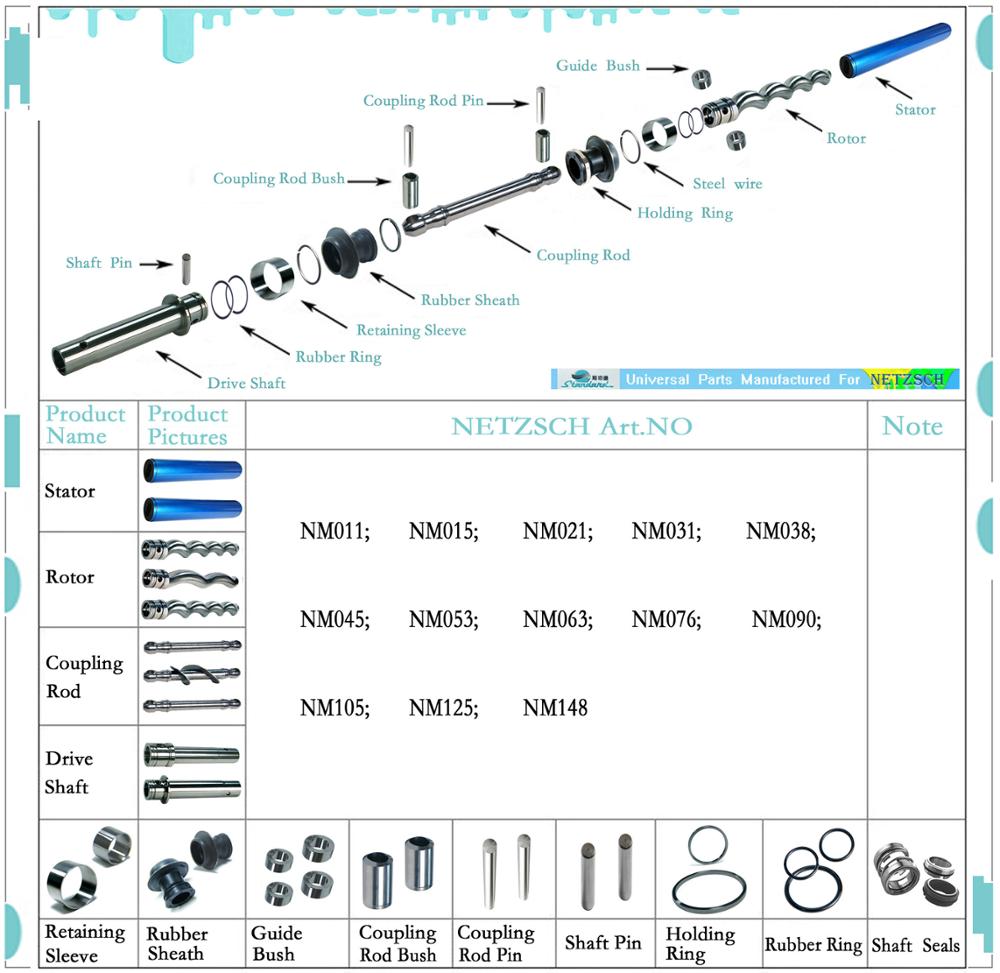

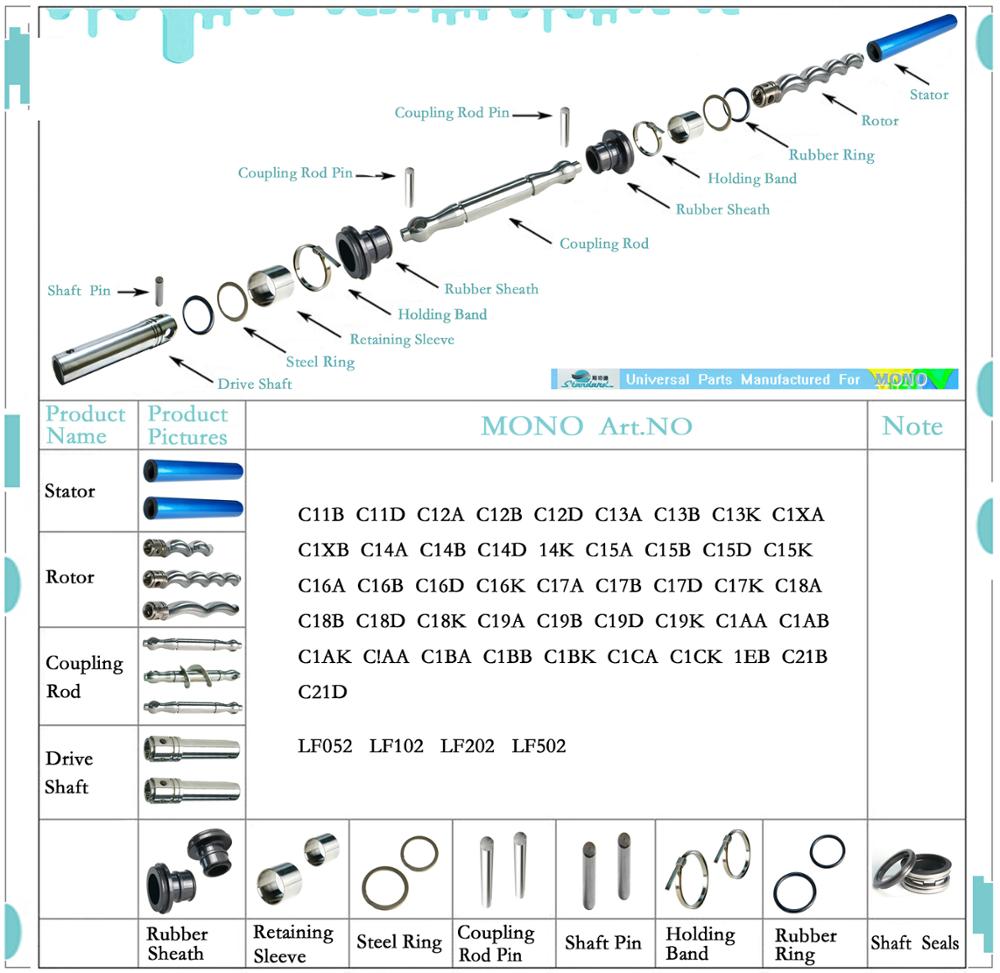

STD Generic Parts Overview

STD has an excellent reputation for the quality of its equipment and parts. In recent years, our mission has been to use our manufacturing and engineering expertise to expand our product offering to include a range of high quality STD general purpose parts for many other brands of progressive cavity (PC) pumps.

We offer STD general purpose parts for use with other brands of progressive cavity pump series below. For others not listed, please contact STD

1) NETZSCH™ 2) SEEPEX™ 3) MONO™

International excellent brand screw pump accessories supply

STD uses its own expertise, manufacturing capabilities and channels to provide a full range of screw pump accessories for major brands in the world (Netzsch, Seepex, Mono, etc.) Shaft joints, pins, pins or complete sets of rotating parts, etc.

We can provide general spare parts under the NETZSCH brand

We can provide general spare parts under SEEPEX brand

We can provide generic spare parts from a single brand

Certification

1) What products does STD offer?

STD provides global solutions for progressive cavity pumps, progressive cavity pump accessories and fluid system products.

Summary of STD's product range

Screw pumps for conveying and metering low to high viscosity media with or without solids

Impregnators for solid and fibrous components in impregnation media

Control systems for monitoring, regulating and controlling processes

Services: Consulting, Commissioning, Maintenance, NETZSCH,Seapac, andmononucleosisGeneral spare parts, repairs and various service contracts

2) Does STD offer custom pumps?

Yes, this is our specialty, we customize different designs and material combinations for each application's modular system. This means that we develop the best technical and most economical solutions for your needs.

3) Can STD spare parts be ordered online?

Yes, STD progressive cavity pumps and spare parts as well as generic accessories from other brands (NETZSCH, SEEPEX. MONO) can be ordered online. To order, please contact us.

4) How fast can my STD pump be delivered?

Typically, standard pumps are delivered within 4 to 6 weeks. In urgent cases, the delivery time may be between 2 and 5 days. Please contact us. Tel: 0086-189 4242 4342

5) Packaging; Shipping

1) Standard export packing: We pack the pump and accessories in a wooden case and put it in a container. Sea and Air Freight. .

2) The marking on the packing box is carried out according to international standards

3) Please check the packaging and integrity of the goods upon receipt, and report any damage to the carrier immediately.

4) If you have special packing requirements, please inform us.

6) Product quality assurance

According to international standards, the whole pump is guaranteed for 1 year,

Spare parts 6 months warranty

Buyer's Note:

1) Can the screw pump run idly?

No, the conveying elements are in permanent contact with each other, which means that dry running of the progressive cavity pump must be avoided. STD dry running protection device provides reliable protection.

2) What temperature is suitable for using STD pump?

STD progressive cavity pumps can be used in temperatures from -20°C to 150°C (-4 to 302°F).

Company Profile

Guangdong Standard Fluid System Co., Ltd. The largest professional manufacturer in South China About: Screw Pumps, Screw Valves, Evacuation System Screw Products

Screw pumps, screw valves, and emptying system screw products have advanced technology, perfect structure, various forms, complete specifications and durability, and are widely used in sewage treatment, chemical industry, papermaking, food processing, pharmaceuticals, energy, environmental protection, 3D printing and other industries .

The company has a team of engineers with rich experience, mature technology, reliable quality and reliable quality of screw pump design, manufacturing, testing and after-sales service. Provide customers with high-quality products, excellent solutions and efficient services in the field of fluid systems.

While producing and developing screw pump products, it also provides general accessories for global screw products (including German Netzsch, Seepex, Viscotec, British mono and other brand accessories) and maintenance customization services, and provides free technical consulting services and improved optimized designs. Our excellent processing capabilities, rich practical experience and mature technical advantages provide a stable guarantee for our products.

our service

1 Our screw pump series products, reasonable price, high-quality service, provide quality inspection. Welcome to OEM.

2 We have a special quality supervision department to ensure the quality of mass production.

3. If there is a quality problem with the product, deal with it as soon as possible, find out the reason, and take responsibility.

4 If you are interested in our products and company, please leave a message or send an email to us, we will reply you within 24 hours

Why choose us?

1 Factory direct sales, no intermediate links, competitive price

2 Our machines are all imported from European machine factories, the quality of the products produced is stable, and inferior equipment is not used.

3 To ensure on-time delivery, purchasing, we can provide the best quality service control, shipping, documentation, etc.

4 We provide samples and OEM service.

5 We will respond to your inquiry within 24 hours.

6 More than 20 years of industry business experience, professional team, make our customers feel at ease when working with us

7 Please contact us by email, we will send you more pictures for more choices of our products.

How to order STD progressive cavity pumps?

1) Sample approval

2) Customers arrange 30% deposit after receiving our PI (Proforma Invoice),

3) We start mass production and complete the production within the agreed delivery time

4) We send shipping documents to customers

5) Client arranges balance payment

6) We arrange shipment and send original documents or telex shipment

|

Address: No. 2, Hengfeng Road, Science and Technology Industrial Park, Nanhai District, Foshan City, Guangdong Province, China |  |

|

| Tel: 0086-18942424342 | |||

| WhatsApp:0086-18942424342 | |||

| WeChat: 0086-18942424342 | |||

| Recipient: Ms. Zhang Jun | |||

| Showroom: https://screwpump.en.alibaba.com | |||

| www.screwpump.top | |||

More styles in our showroom!>>>>>www.screwpump.en.alibaba.com

-

Spot unpowered roof fan exhaust ventilation axial flow fan wind ball workshop cooling cover rotating roof stainless steel AC 220V

-

MONO rubber boots Rubber boots and universal joint sleeves and protective boots for progressive cavity pumps or progressive cavity pumps

-

Single screw pump universal joint Screw pump universal joint Eccentric pump universal joint

-

Metal casting stainless steel dewaxing investment casting pump valve sealing cover processing CNC lathe

-

China Manufacturer Produces High Quality Pump Plate Pump Parts

-

MONO screw pump retaining ring or screw pump single screw pump retaining ring

-

Tire pressure monitoring cover warning cover car tire detection anti-theft tubeless tire cover pressure gauge

-

NETZSCH Spare Parts Guide

-

Copper Centrifugal Pump Stuffing Box

-

SEEPEX Shaft seal for screw pump or Progressing Cavity Pump of Mechanical seal

Other Products

-

$5.00 / piece

$5.00 / piece -

$20.00 / piece

$20.00 / piece -

$38.00 / piece

$38.00 / piece -

$2.00 / piece

$2.00 / piece -

$2.00 / piece

$2.00 / piece -

$58.00 / piece

$58.00 / piece -

$28.00 / piece

$28.00 / piece -

$3.00 / piece

$3.00 / piece -

$48.00 / piece

$48.00 / piece