SEEPEX Shaft seal for screw pump or Progressing Cavity Pump of Mechanical seal

-

Supplier: Guangdong Standard Fluid Systems Co., Ltd. -

Region: Guangdong, China -

Contact: Ms June Zhang -

Price: $28.00 /piece -

Min. Order: 1 piece

| Standard or Nonstandard: | Standard; | Model Number: | BN1-12; |

| Delivery Detail: | 5 days; | Place of Origin: | Guangdong China; |

| Port: | FoShan City of China; | Packaging Detail: | Carton packaging for a single product A number of products with wooden box packaging, each box does not exceed 30 kg; |

| Pump Parts & Accessries: | Wheel axle cap; | NEMA: | shaft seals; |

| Supply Ability: | 10000 Piece/Pieces per Month; | Brand Name: | SEEPEX; |

| Payment Terms: | T/T,Western Union; |

Mechanical seal:Mg1/mg12/mg13

Brand: STD Seals

Application: screw pump, chemical pump, water pump, impurity pump

Applicable industries: smelting, papermaking, refining, fine chemicals, sewage treatment, etc.

Product Features:

Sealing surface: Graphite, cemented carbide, SIC, etc.

Auxiliary seals: nitrile, ethylene propylene, fluorine gum, etc.

Metal components: 304, 316L, etc.

Structural features: Single end face, unbalanced, arbitrary rotation, rubber corrugated pipe

Working ParametersVersion:

Spec.: 10-100mm

Pressure: ≤1mpa

Temperature: -20°C–150°C

Line speed: ≤10m/s

Suitable for medium: sewage, oil and weak corrosive medium

Note:

Mechanical seals precision parts, in the installation process, avoid smashing and bangingseal components!

Non-assembly mechanical seals

1. To assemble mechanical seal static component into the pump cavity gland.

2. When the mechanical seal using V-ring structure, in the installation of special attention to its V-shaped openings must face the medium (or sealing fluid) pressure direction.

3.The mechanical seal components set on the pump shaft (also must make the V-type openings facing the pressure direction) according to the model specification to determine the position of the spring seat and according to the requirements of the adjustment, so that the spring pressure to meet the design requirements. thus ensuring the normal working pressure of the sealing surface. Tighten the screws evenly.

4.The installation of one-way rotation (that is, the loop or hook spring transmission) mechanical seals, especially attention to the spring rotation, its rotation should be the same as the axis rotation direction, so that the spring more tightly. From the mechanical seal to the end of the static ring to see, to determine the rotation direction of the axis, clockwise direction for the right, counterclockwise direction for the left rotation

Second, operation and precautions

1. Mechanical seals was absolutely not allowed dry turn ,the pump must be fully vented before the device starts, so that the media is filled with sealed cavities before the device can be opened.

2. The operation of equipment should strictly follow the following procedures:

3. Before the equipment operation, should start flushing water, 5 minutes later, start the mainframe;

4. If you do not open flushing water, will lead to sealing surface dry friction, high temperature, seal ring burnout and seal ring coking, which will lead to complete failure of the seal. The phenomenon is more prominent in the two-terminal and multi-faceted structures.

5. In the operation of equipment, should always check whether the flushing water is unblocked, pressure to meet the requirements;During operation, flushing water cannot be interrupted or stopped.

6. Tthe best way to operate the pump is continuous work,If you must stop, you should rinse the backflow sediments from the pipes and pump cavities.If the equipment is to be stopped, it must be shut down for 5 minutes before the flushing water can be turned off

Installation drawing

S T D factory availability

1)There are all kinds of accessories in the S T D’s factry, we offer a fast turnaround to help reduce the downtime of equipment, you don’t need to have a lot of inventory.

2)For the spare parts, can be quickly shipped, to ensure that the production won’t be interrupted or reduced to the minimum downtime. With good service and very competitive price, customer can earn time an profit from the cooperation with us.

Highly competitive pricing

During customers become more and more focused on running and maintaining costs,in evaluating the conservation and efficiency of factory, we need to consider priority the price and supply capacity of spare parts.

STD company is using their engineering knowledgeand production capacity, is capable of producing excellent quality and price competitiveness spare parts ( the spare parts of NETZSCH, SPEEDEX, MONO ,VISCOTEC, STD etc. )

Quality Assurance

S T D is a professional R & D and manufacturer of single screw pump and the spare parts, product quality was inspected and approved by customers in professional market, has won customer's recognition and highly praise.

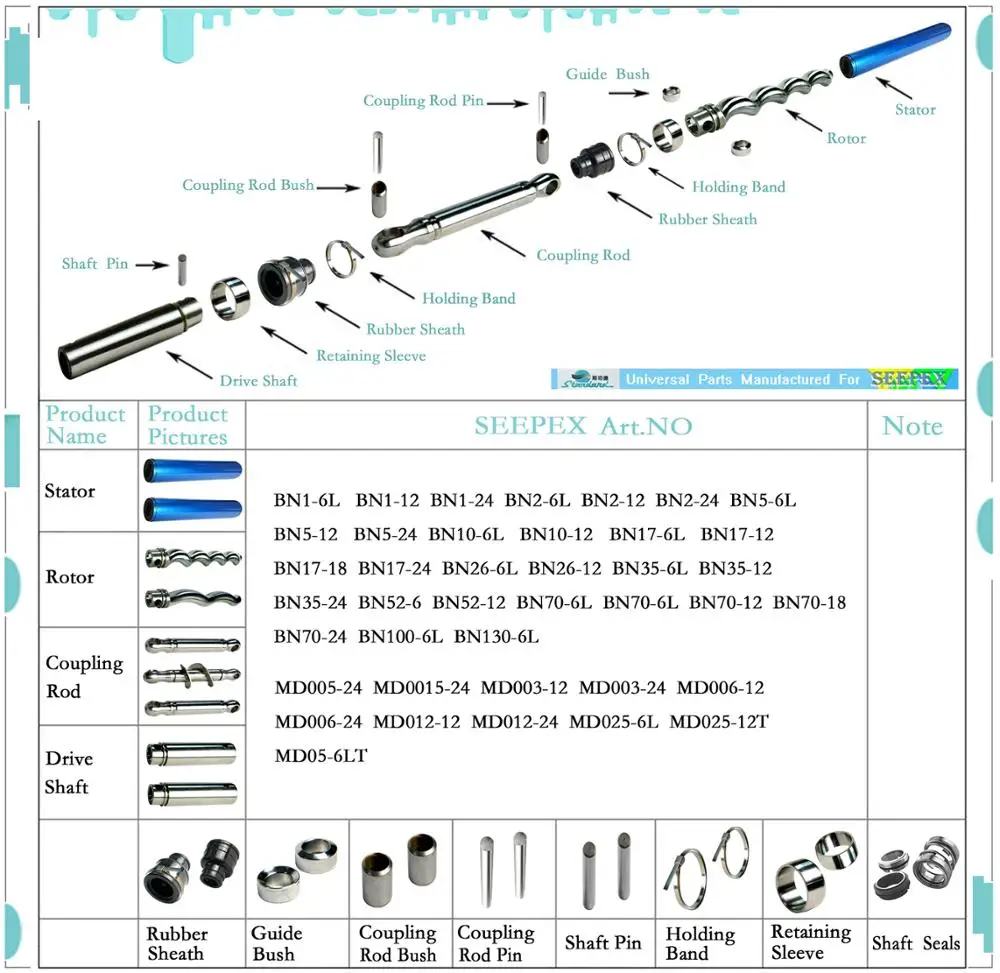

S T D Universal Parts overview

S T D has a reputation for quality in both equipment and parts. Over recent years it has been our mission to use our manufacturing and engineering expertise to expand our product offering to include a range of high quality S T D Universal Parts, suitable for many other brands of progressing cavity (PC) pumps.

We provide S T D Universal Parts to be used with the following ranges of other brands of progressing cavity pumps. For others not listed, please contact S T D

1) NETZSCH™ 2) SEEPEX™ 3) MONO™

International excellent brand screw pump parts supply

STD use their own expertise, manufacturing capabilities and channels to provide the world's major brands (Germany's Netzsch,Seepex, Mono,and so on) a full range of screw pump parts, these accessories performance is good, rugged, durable, including: stator, rotor, transmission shaft, joint shaft, PIN, PIN, or a complete set of rotating parts, etc.

WE CAN PROVIDE THE UNIVERSAL SPARE PARTS OF NETZSCH BRAND

WE CAN PROVIDE THE UNIVERSAL SPARE PARTS OF SEEPEX BRAND

WE CAN PROVIDE THE UNIVERSAL SPARE PARTS OF MONO BRAND

CERTIFICATION

1)What products does S T D offer ?

STD offers screw pump, Screw pump accessories, and the global solution of the fluid system product.

The product range summary of STD

Progressive cavity pumps for conveying and metering low to highly viscous media with or without solids

Macerators for macerating solid and fibrous components in the medium

Control systems for monitoring, regulating and controlling processes

Services: consulting, commissioning, maintenance, NETZSCH ,SEEPEX, and MONO Universal Spare parts, repairs and various service contracts

2)Does S T D supply custom-made pumps ?

Yes, this is our specialty, we customize different design and material combinations for each application's modular system. This means that we develop the best technology and the most economical solution for your needs.

3)Can S T D spare parts be ordered online ?

Yes, S T D screw pumps and spare parts as well as other brands (NETZSCH,SEEPEX.MONO) Universal accessories can be ordered online. For order please contact us.

4)How fast can my S T D pump be delivered ?

Normally, standard pumps are delivered in 4 to 6 weeks. In urgent cases, delivery times between 2 to 5 days may be possible. Please contact us .Telephone: 0086 -189 4242 4342

5)Packing;Transport

1) Standard export packing: We will pack pump and accessories in wooden boxes, put into container. shipmentby sea and air. .

2) The marks on the packing box are executed according to the international standard

3) Please check the packaging and integrity of goods when receiving them, Ifany damaged, please immediately report to the carrier.

4) Please kindly notice us if you have special packing requirements.

6)Product quality guarantee

According to the international standard, whole pump 1 year warranty,

Spare parts 6 months warranty

Buyers Attention:

1)Can screw pump dry running ?

No, the conveying elements are permanently in contact with one another, which means that dry running must be avoided in progressive cavity pumps. The S T D dry-running protection device offers reliable protection.

2)What temperatures is suitable for using S T D pump ?

S T D progressive cavity pumps can be used at temperatures from -20 °C to 150° C (-4 to 302° F).

Company Introduction

Guangdong Standard Fluid Systems Co., Ltd. the largest professional manufacturer in South China about : screw pump, screw valve, emptying system screw products

The screw pump, screw valve, emptying system screw products are advanced technology, perfect structure, various forms, complete specifications, durability, is widely used in sewage treatment, chemical industry, paper, food processing, pharmaceutical, energy, environmental protection, 3D printing and other industries.

The company has an experienced, mature technology, high-quality, reliable screw pump design, manufacturing, testing, after-sales service engineer team. To provide customers with high quality products, excellent solutions and efficient services in the field of fluid systems.

In the production, research and development of screw pump products at the same time, also provides global screw products general accessories (including Germany's Netzsch,Seepex,Viscotec, the British mono, and other branded accessories) and maintenance and custom services, and provide free technical advisory services and improved optimization design. Our excellent processing capacity, rich practical experience and mature technical advantages for our products provide a stable guarantee.

Our services

1 Our screw pump series products, reasonable price, quality service, provide quality inspection. Welcome to sample Custom-made.

2 we have a special quality Supervision Department to ensure the quality of mass production.

3 If the product has quality problems, we will deal with the first time, find out the cause, take responsibility.

4 If you are interested in our products and companies, please leave a message or email us, we will give you an answer within 24 hours

Why choose us ?

1 Factory Direct Sales, no intermediate links, competitive price

2 Our machines are imported from Europe, the original machine factory, the production of stable product quality, do not use low quality equipment.

3 Ensure on-time delivery, procurement, we can provide the best quality of service control, transportation, documentation and so on.

4 We provide samples and OEM services.

5 We will reply to your enquiry within 24 hours.

6 More than 20 years of experience in this industry business, and professional team, so that our customers feel relaxed and comfortable working with us in

7 Please contact us by email and we will send you more pictures for more choices of our products.

How to make an order for S T D screw pump ?

1) Sample approval

2) Client arrange 30% deposit after receiving our PI(proforma invoice),

3) We start bulk production and finish production within agreed lead time

4) We send shipping documents to client

5) Client arrange balance payment

6)We arrange shipment , and send original documents or telex release the goods

More styles in our showroom!>>>>>www.screwpump.en.alibaba.com

-

Spot unpowered roof fan exhaust ventilation axial flow fan wind ball workshop cooling cover rotating roof stainless steel AC 220V

-

MONO rubber boots Rubber boots and universal joint sleeves and protective boots for progressive cavity pumps or progressive cavity pumps

-

Single screw pump universal joint Screw pump universal joint Eccentric pump universal joint

-

Metal casting stainless steel dewaxing investment casting pump valve sealing cover processing CNC lathe

-

China Manufacturer Produces High Quality Pump Plate Pump Parts

-

MONO screw pump retaining ring or screw pump single screw pump retaining ring

-

Tire pressure monitoring cover warning cover car tire detection anti-theft tubeless tire cover pressure gauge

-

NETZSCH Spare Parts Guide

-

Single screw pump eccentric screw pump rubber stator

-

Copper Centrifugal Pump Stuffing Box

Other Products

-

$5.00 / piece

$5.00 / piece -

$20.00 / piece

$20.00 / piece -

$38.00 / piece

$38.00 / piece -

$2.00 / piece

$2.00 / piece -

$2.00 / piece

$2.00 / piece -

$45.00 / piece

$45.00 / piece -

$58.00 / piece

$58.00 / piece -

$3.00 / piece

$3.00 / piece -

$48.00 / piece

$48.00 / piece