Screw pump Spare Parts Rotor

-

Supplier: Guangdong Standard Fluid Systems Co., Ltd. -

Region: Guangdong, China -

Contact: Ms June Zhang -

Price: $58.00 /piece -

Min. Order: 1 piece

| Payment Terms: | T/T,Western Union; | Brand Name: | SEEPEX; |

| Supply Ability: | 5000 Piece/Pieces per Month; | Place of Origin: | Guangdong China; |

| Pump Parts & Accessries: | Pump shaft; | Standard or Nonstandard: | Standard; |

| Packaging Detail: | Carton packaging for a single product A number of products with wooden box packaging, each box does not exceed 30 kg; | Delivery Detail: | 5 days; |

| Model Number: | BN5-6L; | NAME: | SEEPEX screw pump rotor; |

| Port: | FoShan City of China; |

Introduction of screw pump rotor

1The center part of the screw pump is composed of rotor and stator. Screw rotors are usually made of metallic materials and are made into unique twist angles through special cutting machines. A special structure consisting of a steel rotor and an elastic stator makes it capable of conveying materials containing solid particles.

2 The rotor is placed in the stator, sealed together in a helical structure. When the rotor rotates, the internal continuity of the stator is running, the liquid in the closed space runs continuously, conveying out from the suction side of the "No pulsation" and "quantitative" transmission.The outer thread and the thread of the rotor are made according to the special processing;

Material of rotor

Carbon steel, stainless steel, SS304, SS316L,904L etc.

The material of rotor my company commonly used: 40Cr, Cr12mov,SS304, SS316L, 2205 and 904L

Screw pump with different rotor /stator geometries, operating method and conveying principle

The/geometric shape belongs to a single head screw/rotor. With a circular cross-section, a large pitch and a large thread depth, the depth is constantly changing as the rotor rotates in the stator. The cross-section of the stator is the same as that of the rotor, however, the stator is a two-headed internal thread 180 ° apart, and when the stator and the rotor are meshed together, they form 1/2 stator cavities. When the rotor rotates, the continuous forward cavity between the rotor and the stator moves the medium in which the packet is delivered smoothly and continuously from the suction end of the stator to the discharge end.

The flow rate is determined by the pitch, diameter and eccentricity of the rotor/stator, and the speed of the pump.

The outlet pressure depends on the series and the pressure difference of maximum 6bar 85psi per level,

The 2-stage screw pump with s-shape geometry can achieve a pressure difference of 12bar 170psi and hundred percent of flow.

The shape of a single-stage screw pump with L-shaped geometry is the same as that of the S-shaped 2-stage pump, with the same diameter and eccentricity. The rotor/stator screw pitch of L-shaped geometry is twice times than with the S-shape geometry. Therefore, compared with the S-shape geometry with the maximum pressure difference of 6bar 85psi, this pump can be twice times flow of it.

Double head thread geometry stator

The rotor of the double head thread has the Ellipse cross section big pitch and the big thread depth, the rotor is the eccentric circular rotation movement in the fixed stator, the stator also has the same geometrical shape as the rotor, but the stator has a three-head thread which is 120 ° apart.

When the stator and the rotor areocclusal, the 2/3 geometric cavities are formed between them, and when the rotor rotates, the continuous forward cavity between the rotor and the stator is transported smoothly and continuously from the suction end of the stator to the discharge end.

The flow rate is determined by the screw pitch, diameter and eccentricity of the rotor/stator, and the speed of the pump. The outlet pressure depends on the series and the maximum pressure difference 6bar 85psi per level.

The cavity size of the two-headed thread geometry is about 75% of the S/L type, but its cavity is opened two times per turn, and the 1/2-level geometry of the cavity is only opened once per turn,

So it is increases 50% flow rate each turn for the double head thread geometry of the rotor/stator than the S/L type,

Two-head thread geometry of the 2-stage screw pump, with 150% flow rate more than S geometry single stage pump, achieve maximum pressure difference 12bar 170psi.

Double head thread geometry shape dimension of 1-stage is same as screw pump and 2-stage screw pump, the ellipse and eccentricity are the same too. But the screw pitch is twice times the rotor/stator of the two-head 2-stage shape. So with the maximum pressure difference of 6bar 85psi, this pump produces 300% of the flow ratio than S-shape geometry

S T D factory availability

1)There are all kinds of accessories in the S T D’s factry, we offer a fast turnaround to help reduce the downtime of equipment, you don’t need to have a lot of inventory.

2)For the spare parts, can be quickly shipped, to ensure that the production won’t be interrupted or reduced to the minimum downtime. With good service and very competitive price, customer can earn time an profit from the cooperation with us.

Highly competitive pricing

During customers become more and more focused on running and maintaining costs,in evaluating the conservation and efficiency of factory, we need to consider priority the price and supply capacity of spare parts.

STD company is using their engineering knowledgeand production capacity, is capable of producing excellent quality and price competitiveness spare parts ( the spare parts of NETZSCH, SPEEDEX, MONO ,VISCOTEC, STD etc. )

Quality Assurance

S T D is a professional R & D and manufacturer of single screw pump and the spare parts, product quality was inspected and approved by customers in professional market, has won customer's recognition and highly praise.

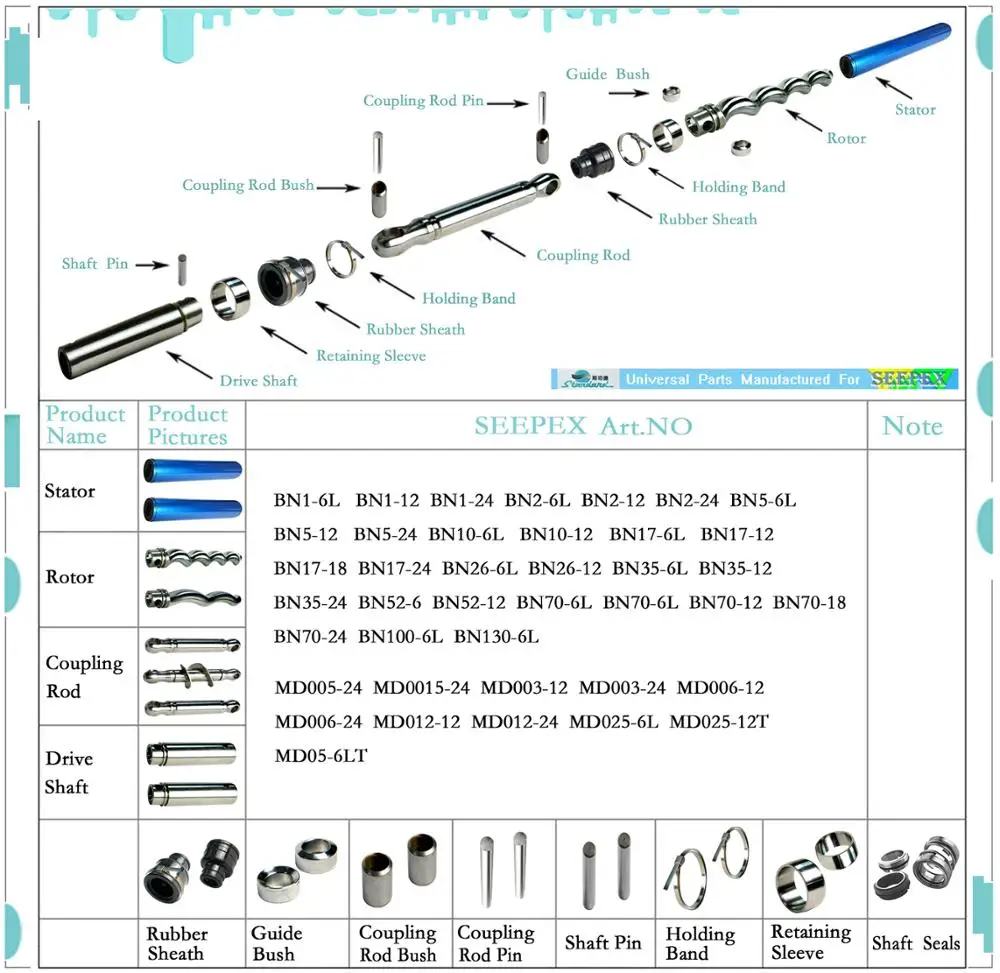

S T D Universal Parts overview

S T D has a reputation for quality in both equipment and parts. Over recent years it has been our mission to use our manufacturing and engineering expertise to expand our product offering to include a range of high quality S T D Universal Parts, suitable for many other brands of progressing cavity (PC) pumps.

We provide S T D Universal Parts to be used with the following ranges of other brands of progressing cavity pumps. For others not listed, please contact S T D

1) NETZSCH™ 2) SEEPEX™ 3) MONO™

International excellent brand screw pump parts supply

STD use their own expertise, manufacturing capabilities and channels to provide the world's major brands (Germany's Netzsch,Seepex, Mono,and so on) a full range of screw pump parts, these accessories performance is good, rugged, durable, including: stator, rotor, transmission shaft, joint shaft, PIN, PIN, or a complete set of rotating parts, etc.

WE CAN PROVIDE THE UNIVERSAL SPARE PARTS OF NETZSCH BRAND

WE CAN PROVIDE THE UNIVERSAL SPARE PARTS OF SEEPEX BRAND

WE CAN PROVIDE THE UNIVERSAL SPARE PARTS OF MONO BRAND

CERTIFICATION

1)What products does S T D offer ?

STD offers screw pump, Screw pump accessories, and the global solution of the fluid system product.

The product range summary of STD

Progressive cavity pumps for conveying and metering low to highly viscous media with or without solids

Macerators for macerating solid and fibrous components in the medium

Control systems for monitoring, regulating and controlling processes

Services: consulting, commissioning, maintenance, NETZSCH , SEEPEX, and MONO Universal Spare parts, repairs and various service contracts

2)Does S T D supply custom-made pumps ?

Yes, this is our specialty, we customize different design and material combinations for each application's modular system. This means that we develop the best technology and the most economical solution for your needs.

3)Can S T D spare parts be ordered online ?

Yes, S T D screw pumps and spare parts as well as other brands (NETZSCH, SEEPEX. MONO) Universal accessories can be ordered online. For order please contact us.

4)How fast can my S T D pump be delivered ?

Normally, standard pumps are delivered in 4 to 6 weeks. In urgent cases, delivery times between 2 to 5 days may be possible. Please contact us .Telephone: 0086 -189 4242 4342

5)Packing;Transport

1) Standard export packing: We will pack pump and accessories in wooden boxes, put into container. shipmentby sea and air. .

2) The marks on the packing box are executed according to the international standard

3) Please check the packaging and integrity of goods when receiving them, Ifany damaged, please immediately report to the carrier.

4) Please kindly notice us if you have special packing requirements.

6)Product quality guarantee

According to the international standard, whole pump 1 year warranty,

Spare parts 6 months warranty

Buyers Attention:

1)Can screw pump dry running ?

No, the conveying elements are permanently in contact with one another, which means that dry running must be avoided in progressive cavity pumps. The S T D dry-running protection device offers reliable protection.

2)What temperatures is suitable for using S T D pump ?

S T D progressive cavity pumps can be used at temperatures from -20 °C to 150° C (-4 to 302° F).

Company Introduction

Guangdong Standard Fluid Systems Co., Ltd. the largest professional manufacturer in South China about : screw pump, screw valve, emptying system screw products

The screw pump, screw valve, emptying system screw products are advanced technology, perfect structure, various forms, complete specifications, durability, is widely used in sewage treatment, chemical industry, paper, food processing, pharmaceutical, energy, environmental protection, 3D printing and other industries.

The company has an experienced, mature technology, high-quality, reliable screw pump design, manufacturing, testing, after-sales service engineer team. To provide customers with high quality products, excellent solutions and efficient services in the field of fluid systems.

In the production, research and development of screw pump products at the same time, also provides global screw products general accessories (including Germany's Netzsch,Seepex,Viscotec, the British mono, and other branded accessories) and maintenance and custom services, and provide free technical advisory services and improved optimization design. Our excellent processing capacity, rich practical experience and mature technical advantages for our products provide a stable guarantee.

Our services

1 Our screw pump series products, reasonable price, quality service, provide quality inspection. Welcome to sample Custom-made.

2 we have a special quality Supervision Department to ensure the quality of mass production.

3 If the product has quality problems, we will deal with the first time, find out the cause, take responsibility.

4 If you are interested in our products and companies, please leave a message or email us, we will give you an answer within 24 hours

Why choose us ?

1 Factory Direct Sales, no intermediate links, competitive price

2 Our machines are imported from Europe, the original machine factory, the production of stable product quality, do not use low quality equipment.

3 Ensure on-time delivery, procurement, we can provide the best quality of service control, transportation, documentation and so on.

4 We provide samples and OEM services.

5 We will reply to your enquiry within 24 hours.

6 More than 20 years of experience in this industry business, and professional team, so that our customers feel relaxed and comfortable working with us in

7 Please contact us by email and we will send you more pictures for more choices of our products.

How to make an order for S T D screw pump ?

1) Sample approval

2) Client arrange 30% deposit after receiving our PI(proforma invoice),

3) We start bulk production and finish production within agreed lead time

4) We send shipping documents to client

5) Client arrange balance payment

6) We arrange shipment , and send original documents or telex release the goods

More styles in our showroom!>>>>>www.screwpump.en.alibaba.com

-

High quality Tatsuno type pump

-

370W self-priming screw pump head accessories screw pump head produced by the manufacturer

-

PCM type single screw pump accessories 25I10/40ID5/45I5/120I5/1I10/180I5/130I5/13I5 stator and rotor

-

Customized precision water pump bearing shaft CNC lathe turned rotating drive shaft stainless steel pump shaft

-

370 watt self-priming screw pump screw pump rubber sleeve screw pump shaft

-

JIANHE M20* 1.5 Piston Pump Parts Pump Elements Spring Plunger Lubrication System Pump Parts

-

Custom Precision Water Pump Bearing Shaft Stainless steel pump shafts

-

Wilo pump spare wheel

-

wilden pump parts assembly pilot sleeve CF 04-3882-99 installed in the diaphragm wilden pump diaphragm

-

100% similar screw pump allweiler stator AE1E0050 AE1E100 AE1E150 AE2E100 AE2E150 AE1E380 AE2E380 4H100 12.4 100.4

Other Products

-

$5.00 / piece

$5.00 / piece -

$20.00 / piece

$20.00 / piece -

$38.00 / piece

$38.00 / piece -

$2.00 / piece

$2.00 / piece -

$2.00 / piece

$2.00 / piece -

$45.00 / piece

$45.00 / piece -

$28.00 / piece

$28.00 / piece -

$3.00 / piece

$3.00 / piece -

$48.00 / piece

$48.00 / piece