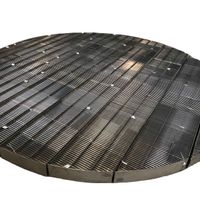

2022 High-efficiency column internals trough liquid distributor

-

Supplier: Anping County Hualai Metal Wire Mesh Co., Ltd. -

Region: Hebei, China -

Contact: Ms Hestia Jiang -

Price: $1955.00 / 1 - 49 sets

$1800.00 / 50 - 99 sets

$1700.00 / >=100 sets -

Min. Order: 1 set

Product details

| Showroom location: | not any | Spare Parts Type: | drawings as customers |

| brand: | courage | Weight (kg): | 100 |

| Main selling point: | custom made | product name: | Tower Internals |

| Packaging Preview: | Certificate: | ISO9001:2008 | |

| port: | Tianjin harbor | size: | custom size |

| Warranty: | 6 months | Video external inspection: | if |

| Supply capacity: | 1,000,000 kg/month woven wire mesh metal structural filler | After Warranty Service: | Online support |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Health status: | new |

| After-sale service: | Online support | pack: | wooden box |

| Mechanical test report: | Not available | type: | custom size |

| place of origin; place of origin: | Hebei china | Applicable industries: | Construction Engineering, Energy and Mining |

| Marketing Type: | 2021 Hot Deals | usage: | liquid dispenser |

| Packaging Details: | Wooden box, carton or as customer's request |

Product Description

liquid dispenser

From a process point of view, the liquid distributor is the most important device inside the column. A distributor is required to distribute the liquid evenly at the top of the packed column.

Liquid distributors must provide sufficient gas passage area to avoid high pressure drop or liquid entrainment.

Choice of Liquid Dispenser

Column diameter mm | specific liquid load cubic meter/square meter*hour | System fouling trend | Turndown ratio | Suitable Liquid Dispenser Type |

250 - 900 | 0.75 - 5 | low-medium | <10:1 | Trough liquid distributor with oil pan Deck liquid dispenser with holes in the dropper |

5 - 30 | low-medium | 2:1 | Disc Liquid Dispenser Trough liquid distributor with oil pan | |

>30 | low-medium | 2:1 | Disc Liquid Dispenser Trough liquid distributor with oil pan Deck Liquid Dispenser | |

>900 | 0.75 - 5 | low-medium | <10:1 | Tank Dispenser Dispenser Deck liquid dispenser with holes in the dropper |

5 - 30 | low-medium | 2:1 | Trough liquid distributor with oil pan Tank Dispenser Dispenser Deck Liquid Dispenser | |

>30 | low-medium | 2:1 | Deck Liquid Dispenser Trough liquid distributor with oil pan |

For standard regulated cleaning systems, we use perforations at the bottom of the distribution tank; for low liquid loads and wide operating ranges, we often use orifice plates, weirs, or additional distribution pipes on the sides of each tank; for systems with a risk of scaling, arrange overflow distribution (eg via weirs on the tank side). Overflow dripper with risk of scaling. Nozzles are especially suitable for tubular distributors in solids-free systems

Features of the Ideal Liquid Dispenser

Wallace manufactures liquid dispensers.

Anti-fouling

gas pressure drop

proper adjustment ability

Even liquid distribution

Higher cross-mixing capability

Liquid Dispenser Comparison

thing | trapezoid | Nozzle Type | pot with bottom hole | Bottom hole slot | pan with overflow | with overflow tank | ||

strength | pressure | gravity | pressure | gravity | gravity | gravity | gravity | |

Distribution quality | middle | High | low to medium | High | High | low to medium | low to medium | |

capacity m3/(m2·h) | 0.25-2.5 | 0.25-10 | A wide range of | A wide range of | A wide range of | A wide range of | A wide range of | |

Tower diameter/m | >0.45 | any | any | Any, often <1.2 | Any, often >0.6 | Any, often <1.2 | Any, often >0.6 | |

plugging degree | High | High | medium to high | middle | middle | low | low | |

air resistance | low | low | low | High | low | High | low to high | |

level requirement | not any | low | not any | high at low load | high at low load | High | High | |

Corrosion Effects | High | middle | High | High | High | low | low | |

The effect of liquid level fluctuations | not any | small | not any | middle | middle | big | big | |

entrainment | High | low | High | low | low | low | low | |

weight | low | low | low | High | middle | High | middle | |

VIEW MORE

You may like

-

Marine Scrubber Vane Demister Droplet Separator Demister

-

1000mm stainless steel elliptical hemispherical conical quasi-spherical head pressure vessel cans

-

China new design sealed top loading arm and fmc loading arm supplier

-

Floor-mounted loading control electronic cabinet with railcar top loading arms for tank farms

-

Manufacturers supply the liquid distributor through the stainless steel liquid distributor

-

Ammonia distillation unit sieve plate stainless steel perforated sieve plate

-

Protect Mail Material Inflatable Airbag Bubble Column Packaging For Cosmetics

-

Rail tank car, road tank car upper and lower loading arm

-

York Mesh 431, 421, 326 Supply, Wire Mesh 2205 Mist Eliminator Factory Supplier

-

Anti-corrosion PP defogging pad for low temperature

Other Products

-

$9.00 / set

$9.00 / set -

$29.90 - $39.90 / set

$29.90 - $39.90 / set -

$28.00 - $29.80 / set

$28.00 - $29.80 / set