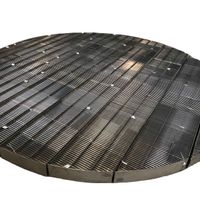

Anti-corrosion PP defogging pad for low temperature

-

Supplier: Anping County Hualai Metal Wire Mesh Co., Ltd. -

Region: Hebei, China -

Contact: Ms Hestia Jiang -

Price: $39.90 / 1 - 5 sets

$29.90 / >=6 sets -

Min. Order: 1 set

Product details

| Wire diameter: | 0.3-0.35mm | Certificate: | ISO9001:2008 |

| Material: | polypropylene | Packaging Preview: | |

| Supply capacity: | 1999 sets/month anti-corrosion PP low temperature defogging pad | figure: | Working temperature below 70℃ |

| Spare Parts Type: | Knitted wire mesh | Warranty: | 6 months |

| Showroom location: | not any | Mechanical test report: | Not available |

| After-sales service provided: | Online support | brand: | Walley |

| usage: | Wet scrubbers, etc. | place of origin; place of origin: | Hebei china |

| Marketing Type: | Hot Products of 2019 | port: | Tianjin harbor |

| Video external inspection: | if | type: | Plastic demister |

| Applicable industries: | Manufacturing, Energy & Mining, Wet Scrubbers | Packaging Details: | Wooden case, or by order. |

| Main selling point: | Good acid resistance, economical cost | payment terms: | letter of credit, wire transfer |

| After Warranty Service: | Online support, spare parts | Health status: | new |

| Local service location: | not any |

Product Description

PP mist eliminator

Polypropylene is a polymer formed by adding propylene. White wax material, transparent appearance and light weight. Density 0.89-0.91g/cm3, flammable. Below 80℃, it is resistant to corrosion by acid, alkali, salt solution and various organic solvents, and oxidative decomposition at high temperature. The PP mesh pad demister is made of PP knitted wire mesh tube. Its recommended operating temperature is below 70 ºC. Such mist eliminators are widely used in scrubbers.

manufacturing process

Material preparation

first,We prepare PP knitted wire mesh rolls and meshes as material. PP knitted mesh can be made in different widths for easy handling in our own workshop. It can be braided with single wire, double wire, co-woven with other materials, etc. We can directly supply PP woven mesh in large quantities.

PP mesh pad

second,According to the order requirements, such as the shape, size, segmentation scheme of the defogger, mesh pad thickness, mesh density, etc., our workers layer PP knitted mesh sheets to make mesh pads. Some customers buy this product instead of PP mist eliminator with grid.

PP mist eliminator with mesh

at last,Our workers add proper PP mesh to the prepared mesh mat to complete the production of the mist eliminator. Sometimes stainless steel mesh is used instead of PP mesh for added strength or to maintain the specific shape of a custom mist eliminator.

Innovative experience

This is a circular mist eliminator with two sections. To make way for the square tube in the center, we designed a slot in each section and implemented it in production. Once installed, they form a suitable square hole for the tube, leaving no gaps at the joint.

As you can see, this is also the design of a mist eliminator with a tube hole. The difference is the segmentation method. The tower has a narrow space with a large gas pipe in the middle. If we make the segments into strips as usual, it will be difficult to install and maintain. And this creative construction method perfectly solves this problem.

The innovation is not so obvious in this photo. Could you please find out? Yes, handle. In some air handling units, such as the intake duct of HAVC, the mesh pad demister is usually installed and pulled out from the side. With our innovative handles on the grid, maintenance will be quick and easy.

This is a PP mist eliminator with a stainless steel frame. It is usually used in ventilation systems. With the help of the ss frame, the mist eliminator can be made in any size and thickness. It also attaches easily to the main unit and retains its shape under higher airflow.

This is a wave type mist eliminator. We are familiar with its capacity is much higher than ordinary flat demister with the same mesh density and thickness. With PP mesh, the mist eliminator is difficult to shape. With the help of ss grid, we can achieve it more easily.

VIEW MORE

You may like

-

Marine Scrubber Vane Demister Droplet Separator Demister

-

1000mm stainless steel elliptical hemispherical conical quasi-spherical head pressure vessel cans

-

China new design sealed top loading arm and fmc loading arm supplier

-

Floor-mounted loading control electronic cabinet with railcar top loading arms for tank farms

-

Manufacturers supply the liquid distributor through the stainless steel liquid distributor

-

Ammonia distillation unit sieve plate stainless steel perforated sieve plate

-

Protect Mail Material Inflatable Airbag Bubble Column Packaging For Cosmetics

-

2022 High-efficiency column internals trough liquid distributor

-

Rail tank car, road tank car upper and lower loading arm

-

York Mesh 431, 421, 326 Supply, Wire Mesh 2205 Mist Eliminator Factory Supplier

Other Products

-

$1700.00 - $1955.00 / set

$1700.00 - $1955.00 / set -

$9.00 / set

$9.00 / set -

$28.00 - $29.80 / set

$28.00 - $29.80 / set

Related Search

brake pad for subaru impreza

brake pad for toyota vios suppliers

low temperatur hermet compressor suppliers

low temperature solder wire

low temperatur check valv suppliers

ceramic brake pad for toyota hilux

brake pad for toyota hilux

cooling pad for laptop

digital writing pad for laptop

cooling pad for computer