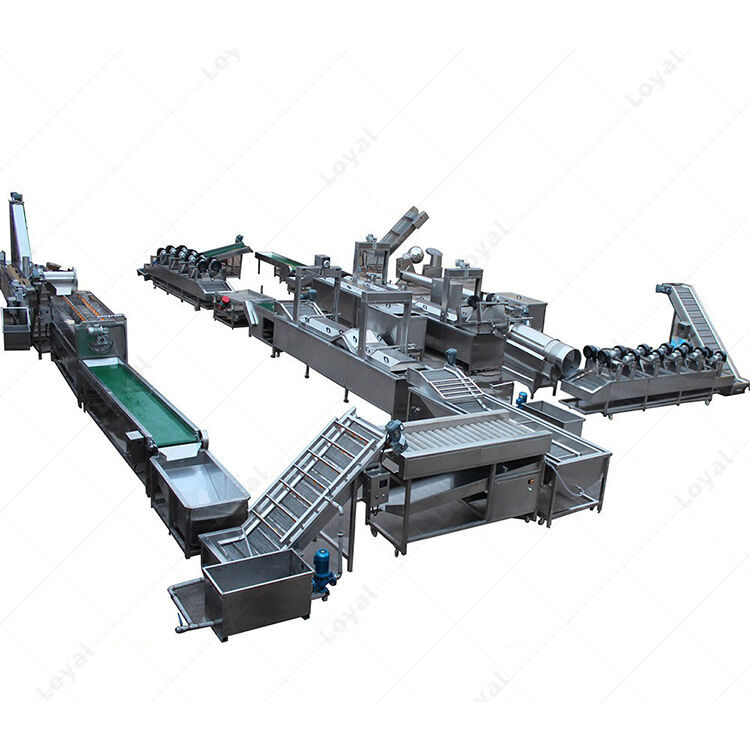

Good Quality Frozen French Fries French Fries Making Machine French Fry Vending Machine Price

-

Supplier: Shandong Loyal Industrial Co.,Ltd. -

Region: China -

Contact: Mr Amy Guo -

Price: $5500.00 /piece -

Min. Order: 1 piece

Fried salad/horn snack processing lineIntroduction:

The production line realizes the mechanized processing of traditional handmade wheat food. It not only continues the crisp and non-greasy taste, but also realizes the infinite innovation of raw materials. Only twin-screw extruders can complete the processes of mixing, cooking, puffing, and molding. If equipped with Sala cutting machine and fryer, we can produce two-dimensional fried snack food such as Salad chips and crusts.friedspeaker machineequippedpatternprocessingmachine,Composite molding machine and fryer, which can produce 3D fried snacks such as horns, pillows, and goldfish.

French fries production lineflow chart:

Mixer--Screw Conveyor--pairscrew extrusionmachine--pulling machine--continuous frying machine--offOil

machine--seasoningmachineThe material is extruded, punched into triangles,Fish shape, then deep fried to taste.This crunchy, nutritious snack with an easily digestible structure is loved by many people around the world.The most important thing is that the waste punching chips can be reused after being ground into powder, which can greatly reduce the production cost.

Features of fried salad/horn snack processing line:

1. Raw materials: rice flour, corn flour, flour or their mixtures are the main raw materials.

2. Products: This production line can produce rice crackers, salad bars, salad slices, puff pastry corners, puff pastry corners, etc. by adjusting the die of the extruder.

3. Output: 120-150kg/h, 180kg/h, 200-250kg/h, 200-250kg/h, 500kg/h, 800-1000kg/h

4. Process: powder mixer → twin-screw extruder → traction cutter → elevator → continuous fryer → seasoning machine

5. Voltage: Three-phase: 380V/50Hz, single-phase: 220V/50Hz, can also be customized according to the local voltage of the country where the customer is located

6. Machine material: All machines are made of stainless steel, and the screws are made of alloy steel. The production line is reasonably designed and has a high degree of automation.

The raw material can be rice flour, corn flour, wheat flour alone or a mixture thereof. Just change the mold, shaping or cutting machine, it can be made into various shapes, such as rod, square rib, diamond, wave, pillow, horn, etc., delicious and not greasy.

French fries snack machine equipment materials:

1. AllFrench fries production lineMade of food grade stainless steel

2. Screw:Alloy steel (38CrMoAl)3. HRC

The hardness is around 60---62, and it has good self-cleaning ability, no need to unload or clean the barrel and screw during baking or refueling.

4. The extrusion cylinder is made of carbon steel, 45 steel and stainless steel coating.

5. The gearbox has automatic lubrication function, which can prolong the life of the gear.

6. The tool is fixed on the die head seat and is driven by a V-belt to rotate.

-

Fully automatic potato chip production line frozen potato chips making machine

-

Factory Price Potato Chips Production Line Fresh French Fries Making Machine Potato Chips Processing Factory

-

HORUS High Quality Automatic Potato Chips Making Machine Potato Shredded Machine

-

Fully Automatic Frozen French Fries French Fries Making Machine Production Line For Sale

-

Tornado manual potato machine made of stainless steel

-

Industrial 300-1000kg/hour Fully Automatic Potato Chips Production Line/Potato Chips Making Machine

-

French fries production line 1/4 Frozen machine

-

400kg/h Automatic Frozen French Fries Production Line Price

-

Potato Chips Production Line Vacuum Frying Potato Chips Maker Batch Fryer

-

High Quality Pringles French Fries French Fries Processing Equipment Potato Chips Production Line Manufacturing Machine Price

Other Products

-

$10900.00 / piece

$10900.00 / piece -

$10900.00 / piece

$10900.00 / piece -

$10900.00 / piece

$10900.00 / piece -

$5500.00 / piece

$5500.00 / piece -

$5500.00 / piece

$5500.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$15000.00 / piece

$15000.00 / piece