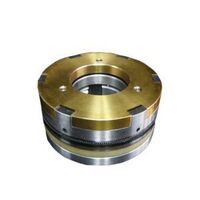

RSCI20 One-way Overdrive Clutch with Freewheel Bearings

-

Supplier: Changzhou Tianniu Transmission Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Doreen Ma -

Price: $85.00 /piece -

Min. Order: 1 piece

| Sales unit: | single product | Thickness (mm): | 35 |

| model: | RSCI20, RSCI20 | Inner ring maximum overrunning speed (r/min): | 315 |

| Torque Capacity (Nm): | 212 | place of origin; place of origin: | Jiangsu, China (Mainland) |

| Seal Type: | seal | Packaging Preview: | |

| application: | mechanical | Packaging Details: | carton or wooden case |

| Applicable industries: | Manufacturing plants, machinery repair shops | delivery time: | 10-15 days |

| Material: | GCr15 | brand: | TN |

| Gross weight per piece: | 1.800 kg | Accuracy class: | P0 P1 |

| type: | Cam clutch | pack: | carton or wooden case |

| Weight (kg): | 1.5 | Single package size: | 19X18X10 cm |

| Bore Tolerance: | H7 |

Product Description

feature

RSCI type is a centrifugal separation one-way flywheel with inner ring rotating. only inside

Games are designed to do whatever you want. It is a non self-supporting type.

Bearings must be provided to ensure concentricity of the inner and outer rings to support axial and

Radial loads, shown on the back.

Concentricity and beat limits must be observed. RSCI type accepts all types of lubricants

Currently used for power transmission equipment. These flywheels can be installed directly

in gearboxes without separate lubrication. Oil mist is generally sufficient. Grease lubrication possible

It is acceptable if the unit is primarily operating at overspeed, such as on an electric motor.

When used as a backstop, it must be checked that the overrunning speed does not fall below

The minimum speed given in the characteristics table.

size and capacity

|

type |

size |

|

speed |

|

number |

|

weight |

||||||||||||

|

RSCI |

dH7 |

TKN1) |

nmax2) |

Nimin 3) |

nimax4) |

D5) |

D1h6 |

D2H7 |

D3 |

D4 |

z |

large |

I |

I1 |

Meter |

I2 |

I3 |

RSCI |

F8 |

|

[mm] |

[Nm] |

[min-1] |

[min-1] |

[min-1] |

[mm] |

[mm] |

[mm] |

[mm] |

|

|

mm |

mm |

mm |

mm |

mm |

mm |

[Kilogram] |

[Kilogram] |

|

|

20 |

212 |

315 |

750 |

15000 |

90 |

36 |

66 |

78 |

M6 |

6 |

35 |

35 |

25 |

5 |

8 |

16 |

1.5 |

0.3 |

|

|

25 |

319 |

300 |

725 |

14000 |

95 |

40 |

70 |

82 |

M6 |

6 |

35 |

35 |

25 |

5 |

8 |

16 |

1.6 |

0.4 |

|

|

30 |

375 |

290 |

700 |

11000 |

100 |

45 |

75 |

87 |

M6 |

6 |

35 |

35 |

25 |

5 |

8 |

16 |

1.8 |

0.4 |

|

|

35 |

550 |

280 |

670 |

11000 |

110 |

50 |

80 |

96 |

M6 |

8 |

35 |

35 |

25 |

5 |

8 |

16 |

2.1 |

0.5 |

|

|

40 |

800 |

260 |

630 |

8000 |

125 |

60 |

90 |

108 |

M8 |

8 |

35 |

35 |

25 |

5 |

10 |

twenty one |

2.7 |

0.7 |

|

|

45 |

912 |

255 |

610 |

7000 |

130 |

65 |

95 |

112 |

M8 |

8 |

35 |

35 |

25 |

5 |

10 |

twenty one |

2.9 |

0.9 |

|

|

50 |

1400 |

235 |

560 |

6000 |

150 |

80 |

110 |

132 |

M8 |

8 |

40 |

40 |

25 |

7.5 |

10 |

twenty one |

4.3 |

1 |

|

|

60 |

2350 |

210 |

510 |

6000 |

175 |

85 |

125 |

155 |

M10 |

8 |

60 |

50 |

36 |

12 |

12 |

35 |

6.5 |

1.8 |

|

|

70 |

3050 |

195 |

470 |

4000 |

190 |

100 |

140 |

165 |

M10 |

12 |

60 |

50 |

36 |

12 |

12 |

35 |

8.6 |

1.9 |

|

|

80 |

4500 |

180 |

440 |

4000 |

210 |

120 |

160 |

185 |

M10 |

12 |

70 |

60 |

36 |

17 |

12 |

35 |

12.5 |

2.6 |

|

|

80M |

5800 |

155 |

375 |

4000 |

210 |

120 |

160 |

185 |

M10 |

12 |

70 |

60 |

46 |

12 |

12 |

35 |

13.1 |

2.6 |

|

|

90 |

5600 |

170 |

410 |

3000 |

230 |

140 |

180 |

206 |

M12 |

12 |

80 |

70 |

36 |

twenty two |

12 |

35 |

17.4 |

3 |

|

|

90M |

8700 |

145 |

350 |

3000 |

245 |

140 |

180 |

206 |

M12 |

12 |

80 |

70 |

46 |

17 |

12 |

35 |

18.3 |

3 |

|

|

100 |

10500 |

145 |

355 |

3000 |

290 |

140 |

210 |

258 |

M16 |

12 |

90 |

80 |

52.6 |

18.6 |

15 |

37 |

28 |

5 |

|

|

100M |

16000 |

140 |

340 |

2400 |

290 |

170 |

210 |

258 |

M16 |

12 |

90 |

80 |

63 |

13.5 |

12 |

35 |

30 |

5 |

|

|

130 |

15750 |

135 |

330 |

2400 |

322 |

170 |

240 |

278 |

M16 |

12 |

90 |

80 |

52.6 |

18.6 |

15 |

37 |

35 |

6 |

|

notes:

1) Tmax = 2 × T KN

2) The maximum permissible torque transmission speed nmax must not be exceeded when transmitting torque.

3) The minimum permissible overrunning speed ni imin shall not decrease during continuous operation.

This minimum speed can be reduced upon request

4) The inner ring extends beyond the keyway according to DIN 6885.1

5) Tolerance +1

Cover F8 must be ordered separately

Product display

Installation example

Packaging and Shipping

Production Process

company information

Customer visit

Certificate

FAQ

-

NUKR 62 for Tracker

-

Japanese IKO cam follower bearing CFS6 CFS6V roller bearing 6x12x9.5mm

-

Sprag type one way bearing DC5476B DC5476B(4C) overrunning clutch bearing 54.765x71.425x16mm

-

China Factory Water Pump Bearing WB1630073 885152 WB Series Water Pump Shaft Bearing

-

High Precision Micro Synthetic Double Cup Sapphire Ring Gasket Ball Ruby Nozzle Ball Watch Compass Gemstone Bearing

-

Factory direct bearing BT2-0026 heavy duty truck hub bearing BT2-0026 93.8x148x135.5mm

-

Automobile water pump bearing WB1730080

-

water pump bearing 885141 885144 885147 885151B 885154

-

AL35 ALP35 High Quality Roller One Way Bearing Clutch

-

FGBGE35ET-2RS GE35UK-2RS GE35C GE35EC-2RS bearing

Other Products

-

$19.00 / piece

$19.00 / piece -

$15.00 - $30.00 / piece

$15.00 - $30.00 / piece -

$30.00 - $50.00 / piece

$30.00 - $50.00 / piece -

$19.00 / piece

$19.00 / piece -

$60.00 - $200.00 / piece

$60.00 - $200.00 / piece -

Hot Sale RLK200 Self-centering Locking Device Locking Assembly Locking Hub Shaft Power Lock Z2 model$3.00 / piece

Hot Sale RLK200 Self-centering Locking Device Locking Assembly Locking Hub Shaft Power Lock Z2 model$3.00 / piece -

$25.00 / piece

$25.00 / piece -

$30.00 / piece

$30.00 / piece