best price vacuum forming machine

-

Supplier: Weifang Yunneng CNC Equipments Co., Ltd. -

Region: Shandong, China -

Contact: Ms stephanie Zhao -

Price: $3800.00 / 1 - 1 sets

$3700.00 / >=2 sets -

Min. Order: 1 set

| Main selling point: | multifunctional | type: | Vacuum forming machine |

| payment terms: | Western Union, wire transfer | Mechanical test report: | if |

| color: | red with white | Packaging Details: | The plywood enclosure protects the two vacuum laminators well |

| Certification: | CE certificate | Forming width (mm): | 2000 mm |

| For suitable materials: | Acrylic fiber; ABS, PC, PS, PVC, PP, etc. | place of origin; place of origin: | China |

| Showroom location: | India, Sri Lanka | Plastic Type: | ABS |

| weight: | 300KG | Supply capacity: | 10 sets per month |

| Suction hole: | 1 or 3 | Voltage: | 380V 50HZ |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | Marketing Type: | normal product |

| Warranty: | 2 years | port: | Qingdao |

| Applicable industries: | Advertising company | Heating power (kW): | 25 kW |

| Maximum forming height (mm): | 600 mm | Core Components Warranty: | 1 year |

| automatic: | Yes | Weight (tons): | 1.3 tons |

| type: | Thermoforming machine plastic cup automatic | brand: | cloud energy |

| Video external inspection: | if | Heating zone: | 1 |

| strength: | 18KW | Auto grade: | semi-automatic |

| Product Category: | sheet | Dimensions (L*W*H): | 3200*1900*1800mm |

| quality: | great | Forming length (mm): | 4000 mm |

| Health status: | new |

Signage 3D Letters Acrylic Signage Vacuum Thermoforming Machine

application:

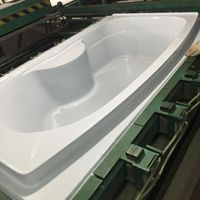

Bathtubs, embossed acrylic letters, pictures, light boxes, signs.

details:

| Model | YN-1212X |

| working size | 1200*1200mm |

| Forming height | 80mm, |

| Larger welded steel tube body |

Thicker steel tube frame with 4 legs (also 4 adjustable screws), The machine is stronger and more stable |

| Quartz heating tube | 24 hours continuous operation 10000 hours service life. Heating the material evenly |

| Smart temperature controller | The heating area adopts a concentrating reflector, Save electricity. |

| cylinder |

There are 6 cylinders, 4 cylinders control the heating furnace, Two-control clamp, easy to operate |

| Focusing reflector |

The temperature is regulated and thermostatically controlled. Assists with heating, thus making the unit energy efficient and saving electricity. |

| warm rock wool | Maintain the temperature, protect workers from being scalded, and prolong the life of electronic components. |

| vacuum pump | 3KW, 100L pump, low noise and high suction |

| oil storage tank | 2000mm long water tank, saving air and better suction |

ABS plastic vacuum thermoforming machine sample

Features of vacuum forming machine

1. This machine adopts a high-power pickup vacuum pump, and the size of the bed is large. custom

Manufactured heating elements have a lifespan of 8-10,000 hours and can be used comfortably

Operates 24 hours a day.

2. The working platform is made of steel and is heat treated to prevent deformation

And prolong the service life of the machine.

3. Adjustable temperature control, constant temperature control. The entire cover is

Covered with heat-reflecting material that aids in heating, resulting in unit energy

Efficient and power saving.

4. The machine is fully automatic. Just place the mold inside the cabinet, close

Cover and press the button.

5. The machine automatically heats and softens the acrylic to the temperature you specify, then starts the pump at the correct temperature and creates the mold in one process.

| Customer praise |

Why choose us

1.18 months equipment warranty and lifetime maintenance.

2. Free installation test before delivery, free training for operators

3. Suggest the solution that best suits the customer's requirements.

4. Provide free training and samples

FAQ

1- What materials can this machine form?

ABS, Acrylic, HIPS, PS, PC

2- How about your delivery time

Usually it takes 10 days after your deposit, we have stock for standard models. If you need it urgently, delivery can be arranged quickly.

3- How about after-sales service?

We have a detailed English manual to guide you in running the machine, and if you have any questions, our engineers will use Teamview to control your software on your computer while chatting with you on Skype.

4- I want to see your machine, where is your factory?

Our factory is located in Weifang City, Shandong Province. You can fly to Weifang Airport. We can pick you up there.

5. How to know your machine with high precision?

The accuracy is mainly in the bending part, please check the sample picture below

Related Products

|

|

|

|

|

|

-

Disposable Foam Plate Production Line/Vacuum Forming Lunch Box Making Machine/Fast Food Foam Plate Production Machine

-

Low Price New Plastic Vacuum Forming Machine to Make Disposable Plates/Foam Tableware/Food Containers

-

Used cup machine for vacuum plastic forming

-

Acrylic Forming/Making/Vacuum Tub Forming Machine

-

Durable desktop acrylic pvc plastic vacuum forming machine

-

PS Expanded Styrofoam Pan Container Pan Tray Food Box Small Production Machine, Ellie Whats 008613780912769

-

FUSHI brand PS EPS thermocol foam board container tray mould machine

-

small mini desktop acrylic pvc plastic vacuum forming machine/thermal vacuum forming machine

-

BSX2030 Super Discount High Modular Acrylic ABS PP Thermoforming Deep Vacuum Forming Machine

-

Acrylic thermoforming machine Signage sign vacuum forming machine plastic sheet vacuum former with CE

Other Products

-

$2900.00 / set

$2900.00 / set -

$3900.00 / set

$3900.00 / set -

$3900.00 / set

$3900.00 / set