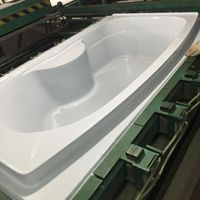

acrylic bathtub forming making thermoforming machine bathtub vacuum forming machine

-

Supplier: Weifang Yunneng CNC Equipments Co., Ltd. -

Region: Shandong, China -

Contact: Ms stephanie Zhao -

Price: $3900.00 /set -

Min. Order: 1 set

| Brand Name: | yunneng; | Payment Terms: | L/C,T/T,Western Union; |

| Product name: | bathtub vacuum forming machine; | type: | bathtub vacuum forming machine; |

| Certification: | CE Certificate; | Automatic Grade: | fully automatic bathtub vacuum forming machine; |

| Condition: | New; | Automatic: | Yes; |

| Place of Origin: | China; | Packaging Detail: | bathtub vacuum forming machine: Plywood case to protect bathtub vacuum forming machine well; |

| Key Selling Points: | Easy to Operate; | Dimension(L*W*H): | 2300*3500*2300mm; |

| Heating area: | 1 or 2; | After-sales Service Provided: | Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Engineers available to service machinery overseas; |

| Weight: | 600KG; | For Suitable Materials: | Acrylic; ABS, PC, PS, PVC,PP and others .; |

| Port: | Qingdao port; | Application: | Plastic by bathtub vacuum forming machine; |

| Product Type: | Sheet; | Color: | Blue; |

| Warranty: | 1 YEAR; | keyword: | bathtub vacuum forming machine; |

| Voltage: | 380V 50HZ; | Power(W): | 26KW; |

| Package Preview: | ; | Applicable Industries: | Printing Shops,Advertising Company; |

| Type: | Vacuum Forming Machine; | Plastic Type: | ABS; |

| Quality: | Great; | Supply Ability: | 10 Set/Sets per Day bathtub vacuum forming machine; |

billboard vacuum forming machine acrylic bathtub forming making thermoforming machinebathtub vacuum forming machine

Acrylic Vacuum Forming Machine Technical Parameter | ||||

Model | YN-1400X | YN-2700XY | YN-3020XY | YN-3700XYC |

Working area (mm) | 1320x1320 | 2620x1320 | 3100x2100 | 3620x2100 |

Total power (kw) | 8 | 16 | 24 | 32 |

Suction holes | 1 | 3 | 3 | 3 |

Heating area | 1 | 2 | 2 | 2 |

Case coating | Electrostatic spray | Electrostatic spray | Electrostatic spray | Spray painting |

Open Method | Manual open/ Pneumatic open | Manual open/ Pneumatic open | Manual open/ Pneumatic open | Sliding open |

Voltage(V) | AC380/50-60HZ or 220v/1p | AC380/50-60HZ | AC380/50-60HZ | AC380/50-60HZ |

Overall size (mm) | 1500*1500*1250 | 2750*1500*1250 | 3190*2200*1250 | 3820*2200*1250 |

Weight (kgs) | 350 | 550 | 1200 | 1800 |

| Working Process |

1) Making molds

2) Seal Acrylic sheet

3) Heat and soft Acrylic

4) Suction, molding, cooling

5) Trimming

| FEATURES |

1.This machine has a high power pick-up vacuum pump and large bed size. Custom made heating elements have a life rated at 8-10 thousand hours and can comfortably run 24 hours a day.

2.Working platform is made of steel and has been heat processed preventing distortion and extending the life of the machine.

3.The temperature control is regulated and thermostatically controlled. The entire lid is covered in heat reflective material assisting in heating thus making the unit energy efficient and saving on power.

4.This machine is fully automatic. Simply place your mold inside the cabinet, close the lid and press the button.

5.The machine automatically heats and softens the acrylic to your specified temperature, then engages the pump at the correct temperature and creates the mold all in 1 process.

| APPLICATIONS |

1) Application

Concave and convex Acrylic letters, pictures, light box and scutcheon.

2)Suitable Materials

Acrylic; ABS, PC, PS, PVC,PP and others .

3)Operating Principle

Acrylic sheet is heated to be soften, and by the suction effect, it rely on mold closely.

| CUSTOMER PRAISE |

| WHY CHOOSE US |

1.18months equipment warranty and maintenance for lifetime.

2.Free installation and test before sending and free training for operators

3.Advice for the solutions best for customers requirements.

4.Free training and sample provided

Click below,you will have a surprise!!!

| FAQ |

1-Which kind of materials i can form by this machine?

ABS,ACRYLIC,HIPS,PS,PC

2- How is your delivery time

Usually it takes 10 days after your deposit,for stardard model we have in stock.if you need urgent,can arrange delivery quickly.

3- What about after-sale service?

We have detail English manual can guide you to run machine,if any doubt,our enginner will use Teamview to

control your software on your computer,meanwhile chat with you on skype.

4- I want to see your machine,where is your factory?

Our factory is located in Weifang City,Shandong Province. you can take flight to Weifang Airport.we can pick you up there.

5.How to know your machine with high precision?

The precision is major in bending part,please check the sample picture as follow

-

Disposable Foam Plate Production Line/Vacuum Forming Lunch Box Making Machine/Fast Food Foam Plate Production Machine

-

Low Price New Plastic Vacuum Forming Machine to Make Disposable Plates/Foam Tableware/Food Containers

-

Used cup machine for vacuum plastic forming

-

Acrylic Forming/Making/Vacuum Tub Forming Machine

-

Durable desktop acrylic pvc plastic vacuum forming machine

-

PS Expanded Styrofoam Pan Container Pan Tray Food Box Small Production Machine, Ellie Whats 008613780912769

-

FUSHI brand PS EPS thermocol foam board container tray mould machine

-

small mini desktop acrylic pvc plastic vacuum forming machine/thermal vacuum forming machine

-

best price vacuum forming machine

-

BSX2030 Super Discount High Modular Acrylic ABS PP Thermoforming Deep Vacuum Forming Machine

Other Products

-

$3700.00 - $3800.00 / set

$3700.00 - $3800.00 / set -

$2900.00 / set

$2900.00 / set -

$3900.00 / set

$3900.00 / set