Rotary wood dryer Small dryer, equipment for rotary drying of wood sawdust boiler, rotary dryer factory price

-

Supplier: Henan Baichy Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Eva Zhao -

Price: $7714.00 /piece -

Min. Order: 1 piece

| Health status: | new | Packaging Preview: | |

| Key words: | Tumble Dryer | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram, through negotiation |

| Video external inspection: | if | Core components: | bearing |

| Packaging Details: | 1. Standard container. 2. Naked packaging. 3. Wooden boxes, etc. | application: | chemical processing |

| Processing material: | Ore, slag, coal, metal powder, clay, diatomaceous earth, kaolin, etc. | product name: | Wood sawdust tumble drying equipment factory price tumble dryer |

| Marketing Type: | Hot Products of 2019 | Motor Power: | 7.5-75kw |

| Voltage: | 380V | Weight (kg): | 30000 |

| port: | Shanghai, Qingdao, Tianjin | application: | Mineral dressing, building materials, other drying industries |

| place of origin; place of origin: | Henan, China | After-sales service provided: | Engineers can repair machinery overseas |

| brand: | Pocky | Mechanical test report: | if |

| Core Components Warranty: | 1 year | strength: | 6KW |

| color: | customer request | Supply capacity: | 100 Inexpensive Washer and Dryer Packages per Month |

| Maximum input gas: | 850℃ | Main selling point: | easy to operate |

| Showroom location: | Saudi Arabia, Pakistan, South Korea, Bangladesh, Kazakhstan, Kyrgyzstan, Uzbekistan, Tajikistan, Australia | capacity: | 2.5t/h -36t/h |

| type: | Spin drying equipment | Install: | Engineer's Guide |

| Dimensions (L*W*H): | 800X1000X1200 | Applicable industries: | Building Materials Store, Construction Engineering, Energy & Mining |

| Warranty: | 1 year |

Small Dryer Wood Rotary Dryer, Wood Sawdust Rotary Drum Drying Equipment, Factory Price Rotary Dryer

Baichy Triple Cylinder Dryer Triple Cylinder Dryer Hot Sale--Introduction

The three-cylinder rotary dryer is mainly suitable for drying slag, sand, coal, fly ash, iron powder, ore, quartz sand and other granular materials. It has the following characteristics:

1. The barrel is self-protected, and the thermal efficiency can reach 95%. The total length of the dryer is reduced by about 50% compared with the single cylinder, and the land investment is reduced by about 50%

2. The cylinder is welded with heat-resistant and wear-resistant steel plate, which has long service life and convenient maintenance. High thermal efficiency, the outer cylinder temperature is below 60°C (the outer cylinder temperature of a single cylinder is as high as 150°C)

3. The air outlet temperature is low, and the dust collector has a long service life. It can also be directly connected to the air box pulse bag filter.

4. No gear and pinion transmission, using wheels to rotate, the whole machine is operated horizontally, which makes the system simple and reasonable.

5. The air heater can be equipped with a boiling furnace or an oil furnace, which can dry materials below 20mm.

6. The final moisture index can be adjusted according to customer requirements.

Rotary dryers are widely used in building materials, metallurgy, chemical industry, cement and other fields. It can dry slag, coal powder, mineral powder, clay, sand, limestone, etc. It consists of a rotating body, a lifting blade, a driving device, a supporting device, etc. The dryer has the advantages of reasonable structure, high efficiency, low energy consumption and convenient transportation.

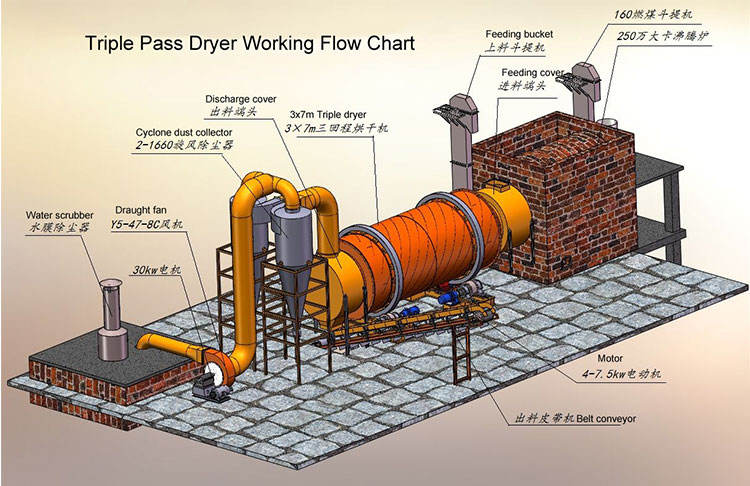

working principle

1. The material first enters the inner cylinder. Since the cylinder is fixed with a spiral plate, when the dryer rotates, the spiral plate will stir the material to make the material move.

2. When the material reaches the right side of the drum, it will enter the second drum for further drying.

3. The same working principle, the material enters the outer cylinder again. During the drying process, the material will be dried three times, and the material can be completely dried during this process.

| Model | Outer cylinder diameter (m) | Length of outer cylinder (m) | Drum volume (m³) | Speed (r/min) | maximum. Airflow temperature (℃) | Production capacity (t/h) | Power (kW) |

| 2.0*4m | 2 | 4 | 12.56 | 4-10 | 700-750 | 8-15 | 5.5x2 |

| 2.2*5m | 2.2 | 5 | 18.99 | 4-10 | 700-750 | 12-20 | 5.5x2 |

| 2.5*6m | 2.5 | 6 | 29.43 | 4-10 | 700-750 | 18-28 | 7.5x2 |

| 2.8*6m | 2.8 | 6 | 36.92 | 4-10 | 700-750 | 25-35 | 11x2 |

| 3.0*6m | 3 | 6 | 42.39 | 4-10 | 700-750 | 30-40 | 7.5x4 |

| 3.0*7m | 3 | 7 | 49.45 | 4-10 | 700-750 | 30-45 | 7.5x4 |

| 3.2*7m | 3.2 | 7 | 56.27 | 4-10 | 700-750 | 35-55 | 11x4 |

| 3.6*8m | 3.6 | 8 | 81.39 | 4-10 | 700-750 | 55-75 | 18.5x4 |

| 4.0*10m | 4 | 10 | 125.60 | 4-10 | 700-750 | 70-100 | 22x4 |

1. Are you a manufacturing company or a trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for stock, 15-30 days for mass production.

3. What is your payment method?

30% T/T prepayment, 70% balance before shipment.

4. How long is the warranty period? Does your company provide spare parts?

one year. Spare parts for you at the lowest cost.

5. If I need complete crushing equipment, can you build it for us?

Yes, we can help you build a complete production line and provide you with relevant professional advice. We have built many mining projects in China and overseas.

-

Best quality 10kg 15kg freeze dryer food drying freeze dryer price household oil-free vacuum pump usa ready stock

-

Vacuum freeze dryer price

-

Household 6kg 8kg fruit food mini vacuum drying household freeze dryer freeze dryer with vacuum pump machine US spot

-

Mini Vacuum Freeze Dryer For Sale

-

Digital Display Multifunctional Combination 8 in 1 Heat Press Machine Sublimation Printing T-shirt Cup Tray Hat Printing

-

Vacuum drying machine, milk powder for vacuum drying

-

Factory price mini industrial vacuum food freeze dryer price

-

220V / 110V Household Professional Food Dehydrator Fruit Dryer

-

Stainless Steel Vacuum Chamber Vacuum Degassing Chamber Glass Cover Silicone for Evacuating and Protecting Food

-

2019 China Laboratory Industrial Small Freeze Dryer Price For Sale

Other Products

-

$99999.00 / set

$99999.00 / set -

$5000.00 / set

$5000.00 / set -

$5600.00 / set

$5600.00 / set -

$24580.00 / set

$24580.00 / set -

$23200.00 / set

$23200.00 / set -

$7714.00 / set

$7714.00 / set -

$2470.00 / set

$2470.00 / set