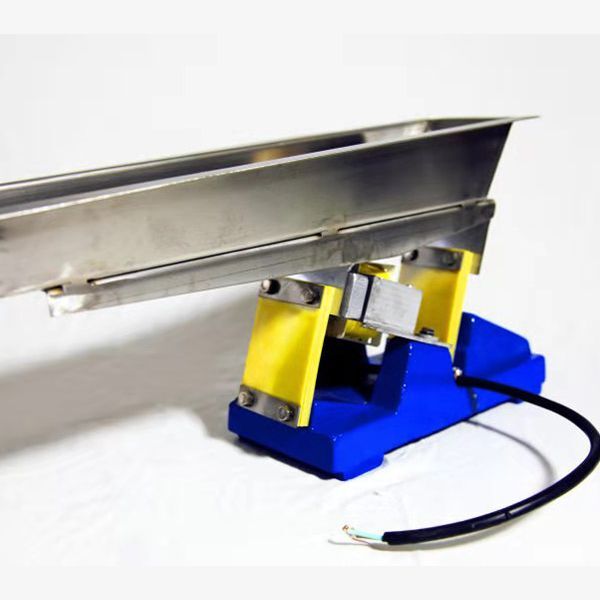

Automatic supplier of quantitative packaging with electromagnetic vibration Micro GzV

-

Supplier: Haian Flourishing Machinery Equipment Co., Ltd. -

Region: Jiangsu, China -

Price: $80.00 /set -

Min. Order: 1 set

| After Warranty Service: | Online support | Certification: | ISO9001 |

| application: | Food/Chemistry/Pharmaceutical | weight: | customer request |

| Marketing Type: | Hot Products of 2020 | Local service location: | not any |

| brand: | flourishing | place of origin; place of origin: | Jiangsu, China |

| Showroom location: | not any | Supply capacity: | 50 sets per week |

| Dimensions (L*W*H): | customer request | Core components: | Electromagnets and Coils |

| port: | Shanghai | Applicable industries: | Farm, Home Use, Energy & Mining, Pharmaceutical, Food, Light Industry, Chemical, Packaging |

| Packaging Preview: | type: | feed pellet machine | |

| Mechanical test report: | if | Video external inspection: | if |

| Warranty: | 1 year | Health status: | new |

| After-sales service provided: | Video technical support, online support | Core Components Warranty: | 1 year |

| commodity: | GZV3 Electromagnetic Vibration Feeder | product name: | vibrating feeder |

| payment terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram | Packaging Details: | carton packing or your wish |

| Capacity (tons/hour): | 1000 |

GZV vibrating feeder

A vibratory feeder is a machine that uses vibration to orient and feed small parts into an assembly line.

feature

The utility model is small in size, light in weight, simple in structure, convenient in installation and low in operating cost;

It adopts half-wave rectification control and can be used for stepless regulation.

The feeder throws the part up in the continuous feeding process, which wears down the small groove.

To reduce noise, increase life and feed efficiency, the inside of the bowl is usually coated with polyurethane.

The vibrator is controlled by the control box.

Technical parameters of GZV vibrating feeder | ||||||||||||||||

Model | GZV1 | GZV2 | GZV3 | GZV4 | GZV5 | GZV6 | GZV8 | |||||||||

Capacity (t/h) | 0.1 | 0.5 | 1 | 2 | 4 | 6 | 8 | |||||||||

Double amplitude (mm) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |||||||||

Frequency (tim/min) | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | |||||||||

Power (Watts) | 5 | 8 | 20 | 25 | 30 | 50 | 100 | |||||||||

control equipment | Model | XKZV-Ⅱ | ||||||||||||||

control method | Controlled Half-Wave Rectifier | |||||||||||||||

Voltage | 220 | 220 | 220 | 220 | 220 | 220 | 220 | |||||||||

Frequency (HZ) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |||||||||

Current (A) | 0.08 | 0.12 | 0.15 | 0.2 | 0.25 | 0.6 | 1.0 | |||||||||

weight | 4 | 7 | 12 | 18 | 27 | 45 | 60 | |||||||||

The overall size of the host is shown in the figure below

Model | Dimensions | ||||||||||||||||

Second | B1 | B2 | B3 | large | L1 | L2 | H | H1 | |||||||||

GZV1 | 40 | 60 | 50 | 80 | 200 | 273 | 92 | 20 | 155 | ||||||||

GZV2 | 60 | 80 | 50 | 80 | 300 | 374 | 95 | 30 | 168 | ||||||||

GZV3 | 80 | 110 | 60 | 100 | 400 | 480 | 224 | 40 | 222 | ||||||||

GZV4 | 100 | 130 | 70 | 120 | 500 | 568 | 310 | 50 | 256 | ||||||||

GZV5 | 120 | 150 | 70 | 120 | 550 | 630 | 310 | 60 | 295 | ||||||||

GZV6 | 200 | 240 | 120 | 180 | 300 | 760 | 440 | 70 | 330 | ||||||||

GZV8 | 300 | 340 | 180 | 230 | 1000 | 1050 | 560 | 80 | 340 | ||||||||

Design and installation of hopper feeder

In order to ensure the normal operation of the feeder, the installation of the hopper should pay attention to several points.

There should be a 5mm gap between the discharge port and the feed trough to ensure that the hopper is not affected by the feeding process.

The outlet of the chute should be designed to be inclined to avoid the vertical pressure directly pressing on the feeder, otherwise it will seriously affect the efficiency of the feeder.

2. Installation

The size of the opening of the hopper should ensure that enough material is obtained, and a gate should be set to adjust the amount of material.

GZV series seat structure vibrating feeder, flat mounted on the support plate

-

High efficiency vibrating feeder for marble stone in reliable quality

-

Underground Mining Shovel XDCY-1A Diesel Scraper Mining Equipment

-

GZ series mine vibrating screen machine electromagnetic vibrating feeder for sale

-

Swing Feeder Disc Screening Machine

-

490X110 ZSW vibrating bar feeder with screening function for stone crushing plant

-

Automatic Heavy Duty Apron Feeder Apron Feeder for Ore Feeding Equipment

-

Chinese Small Vibrating Power Supply GZ Price

-

China limestone clinker apron feeder

-

Made in China, factory price for mini small portable vibrating feeder

-

Custom Small Vibro Vibrating Vibrator Feeder Using PLC Controller

Other Products

-

$80.00 / set

$80.00 / set