GHL WJT Fertilizer Powder Series High Speed Shear Mixing Granulator Wet Mixing Fertilizer Powder Granulator RMG Machine

-

Supplier: Jiangyin Lingling Machinery Manufacturing Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Jackee Wang -

Price: $3000.00 /set -

Min. Order: 1 set

| Weight (kg): | 280 | Health status: | new |

| port: | Shanghai | Marketing Type: | stock available |

| Video external inspection: | if | payment terms: | L/C,Western Union,T/T |

| Type of machine: | granulator, granulator | Applicable industries: | Manufacturing plants, farms, construction projects, advertising agencies |

| Warranty: | 1 year | Output (kg/hour): | 3 |

| Supply capacity: | 2 sets per month | Dimensions (L*W*H): | depending on model |

| Material: | Stainless steel | Packaging Details: | GHL Series High Shear Mixing Granulator Wooden Box Wet Mix Fertilizer Powder Granulator |

| Main selling point: | competitive price | Core components: | Bearings, motors |

| After-sales service provided: | Engineers can repair machinery overseas | Showroom location: | not any |

| place of origin; place of origin: | Jiangsu, China | Core parts warranty: | 1 year |

| Product Category: | particles, etc. | Power (kW): | 1.5 |

| Mechanical test report: | if | Voltage: | 220V/380V |

| brand: | LL brand |

GHL Series High Shear Mixer Granulator Wet Mixed Fertilizer Powder Granulator

main application

High-speed mixing granulator is widely used in pharmaceutical, food, chemical, light industry and other industries. etc., mix the powdered material and granulate.

working principle

The mixing and granulation procedures are done in the same vessel of the granulator. The powdery material in the static conical container is kept in a semi-flow rolling state under the stirring of the stirring paddle, and is fully mixed. After pouring the binder, the powdery material gradually becomes thinner, the wet particles become wet, the shape begins to take on the shape of a paddle and the inner wall of the container, and the powdery material becomes loose and soft. Through the action of the granulation paddle, the soft material gradually becomes small, moist granules of the same size.

feature

1. Pneumatic automatic lift, easy to close and operate.

2. Conical cavity, the material rolls evenly.

3. Open the window, easy to operate.

4. Touch screen, dynamic working screen and vivid operation.

5. 45 degree discharge port, the particles are completely discharged.

6. The V-shaped granulation blade works in a mixed motion mode, so that the material will not enter the gap between the V-shaped granulation blade and the blade to form a corner, so it can be mixed evenly.

7. The interlayer jacket is cooled, and the temperature is automatically controlled to improve the quality of the particles.

8. The 36-degree zigzag paddle works in three-dimensional motion. The distance between the stirring paddle and the surface of the boiler button is 0.5-1.5mm, and the stirring is uniform. There is less residue on the furnace wall, which can reduce friction and save energy by 25%.

9. Labyrinth sealing structure. The rotating shaft cavity can be sprayed and cleaned automatically, with reliable sealing and convenient cleaning.

|

thing |

GHL-10 |

GHL-50 |

GHL-150 |

GHL-200 |

GHL-250 |

GHL-300 |

|

Volume (L) |

10 |

50 |

150 |

200 |

250 |

300 |

|

Production capacity (kg/batch) |

3 |

15 |

50 |

80 |

100 |

130 |

|

Stirring speed (rpm) |

300/600 |

300/210 |

270/180 |

270/180 |

188/130 |

160/110 |

|

Stirring power (kw) |

1.5/2.2 |

4/5.5 |

9/11 |

11/14 |

11/14 |

11/14 |

|

Cut off power (kw) |

0.85/1.1 |

1.5/2.2 |

2.4/3 |

3.3/4 |

3.3/4 |

4.5/5.5 |

|

Cutting speed (rpm) |

1500/3000 |

|||||

|

Working time (minutes) |

8-15 |

|||||

|

Granularity (mesh) |

20-80 |

|||||

Above is our technical data. for reference only. We can also design different varieties according to customers' requirements.

Please let us be more honest, any questions will be answered 100% sincerely and very efficiently by contacting me.

Contact information is on our website https://jylljx618.en.alibaba.comContact us page.

===>Contact me now for new and live videos/photos atvideo call!

Still looking for good and genuine manufacturers in China?

May I invite you to visit us? Please. You have found us.

Click to send an inquiry now! ! !

-

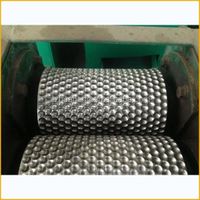

Chicken manure granulator fertilizer/twin roll extrusion granulator fertilizer for sale

-

Industrial large capacity ZL rotary dry granulator granulator mixing granulator food powder processing production line

-

Ganulator Machine Chemicals, Minerals, Inorganic Powder Granulator Fertilizer Double Roll Press Machine Customized 15kw, 30kw CN; JIA 1t

-

Cat litter bentonite granulator/dry powder granulator

-

Organic fertilizer granulator

-

Latest Design Urea Fertilizer Production Equipment

-

1000-1800 kg organic fertilizer bentonite pellet machine per hour

-

Fully automatic urea fertilizer plant/NPK fertilizer production line fertilizer machine

-

Disc Granulator Fertilizer Disc Granulator

-

High quality organic npk compound fertilizer making machine drum granulator for sale

Other Products

-

$5000.00 / set

$5000.00 / set