Latest Design Urea Fertilizer Production Equipment

-

Supplier: Henan Tongda Heavy Industry Science And Technology Co., Ltd. -

Region: Henan, China -

Contact: Ms TD- Billie -

Price: $6300.00 / 1 - 9 sets

$3100.00 / >=10 sets -

Min. Order: 1 set

| Disk diameter: | 3600mm | Origin: | Henan, China |

| Warranty: | 1 year | Disc height: | 450mm |

| Weight (kg): | 2000 | Supply capacity: | 10 sets per month |

| Output (kg/h): | 100000 | Tray diameter: | 3-50mm round tray |

| Health status: | new | output: | 4-6 tons/hour |

| Material one: | Agricultural waste: straw, bean dregs, cotton dregs, etc. | size: | 4100*2900*3800mm |

| Granulation rate: | >95% | Product Category: | fertilizer |

| port: | Qingdao port (nearest); Shanghai port; Tianjin port; Guangzhou port | payment terms: | L/C, T/T, Western Union |

| Power (kW): | 18.5 | Certification: | SGSISO9001-2015 |

| spinning speed: | 13 rpm | Applicable industries: | Building material stores, manufacturing plants, farms, energy and mining |

| Voltage: | 220V/380V or customized | usage: | Production of organic fertilizer granules |

| Packaging Details: | Professional standard export packaging (wooden box/container/customized according to customer's specific requirements) | brand: | Mastery |

| After-sales service provided: | Free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support, online support | Material 2: | animal manure; industrial waste; domestic waste |

| Type of machine: | Granulator |

The latest design organic urea fertilizer production equipment

1. What is organic fertilizer?

- In the current situation, the practice of using organic fertilizers in agricultural fields has significant environmental benefits over the use of chemical fertilizers, and this practice has become very important.

- Organic fertilizers differ from chemical fertilizers in that they build healthy soil while nourishing plants. They are considered a more environmentally friendly option. Soils that contain a lot of organic matter remain loose and light, retain more water and nutrients, and promote the growth of soil microbes, which promote healthier plants and root development.

2. What are the advantages of organic fertilizer?

Enhance the ability of soil to resist cold and drought

- With continuous fertilization, the soil will become more and more fertile, the land is resistant to cold and drought, and the fruit trees can get a good rest.

Improve soil and reduce salt damage

- Adjust pH, balance soil PH value, increase soil permeability, and promote the formation of particle structure.

Greatly improve the quality of agricultural products

- Fruits are sweetened and colored, and the original flavor of vegetables is restored;

- Increase the chlorophyll content of tea leaves and reduce pesticide and fertilizer residues;

- Contains EM bacteria, which can fix nitrogen, remove phosphorus, release potassium, increase chlorophyll content in plants, and significantly increase crop yield.

Increase the microbial content of the soil

- Inhibit the growth and reproduction of pathogenic fungi in the soil, improve the disease resistance and continuous cropping ability of crops.

- Promote seed growth and increase crop photosynthesis

- Promotes early germination and rooting of seeds and rhizomes, and a well-developed root system.

- Improve photosynthesis of crops, adjust the rational distribution of nutrients, promote rapid fruit expansion and early coloring, and make fruits ripen 7-10 days in advance.

3. Where can I get organic fertilizer?

Commercial organic fertilizers:

- Industrial waste: such as distiller's grains, vinegar grains, cassava residues, sugar residues, furfural residues, etc.

- Municipal sludge: such as river sludge, sewage sludge and other organic fertilizer raw material production and supply base classification: silkworm excrement, mushroom slag, kelp slag, phosphoric acid citric acid slag, cassava slag, protein sludge, glucuronic acid slag, amino acid humic acid, Oil residue, grass ash, shell powder, concurrent operation, peanut shell powder, etc.

Bio organic fertilizer:

- Agricultural waste: such as straw, soybean meal, cotton meal, etc.

- Livestock and poultry manure: such as chicken manure, cattle, sheep and horse manure, rabbit manure;

- Household waste: such as kitchen waste;

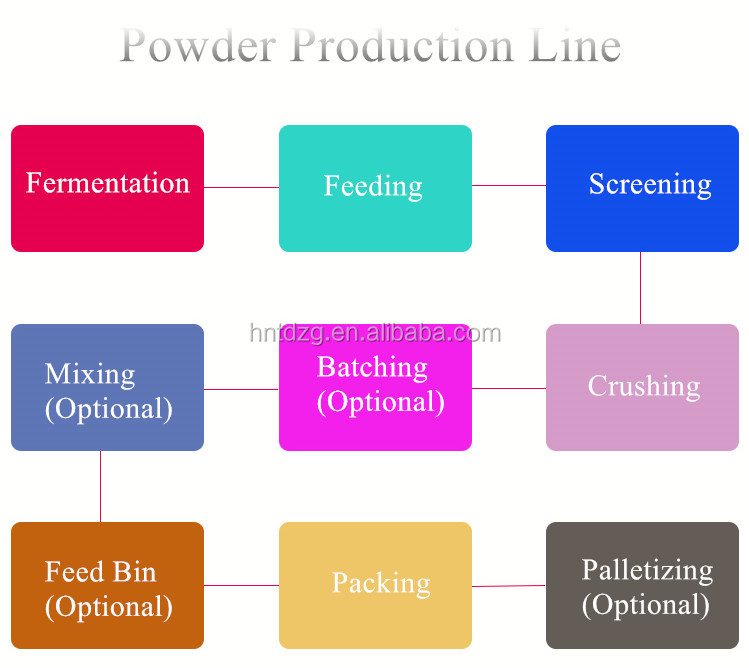

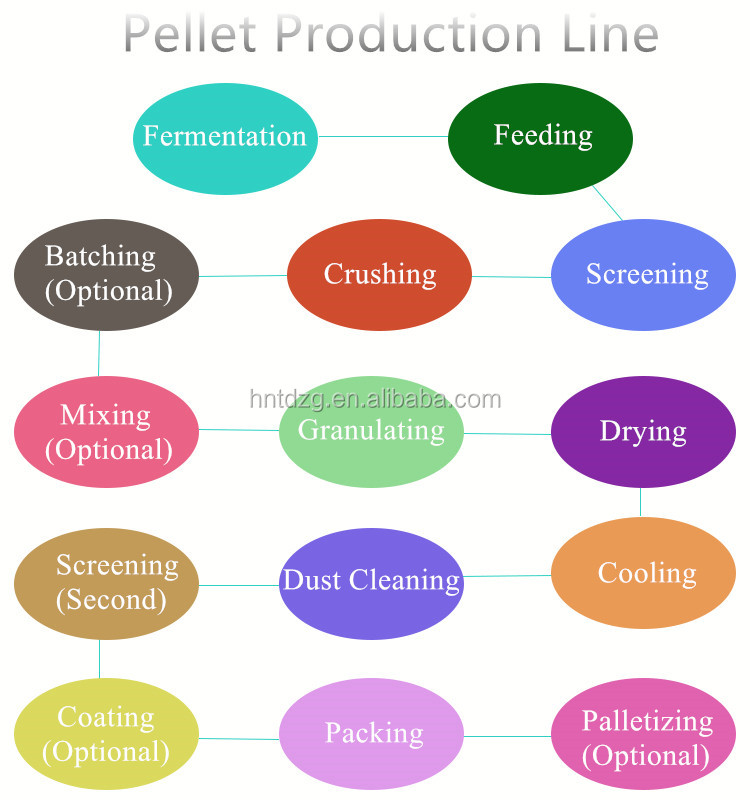

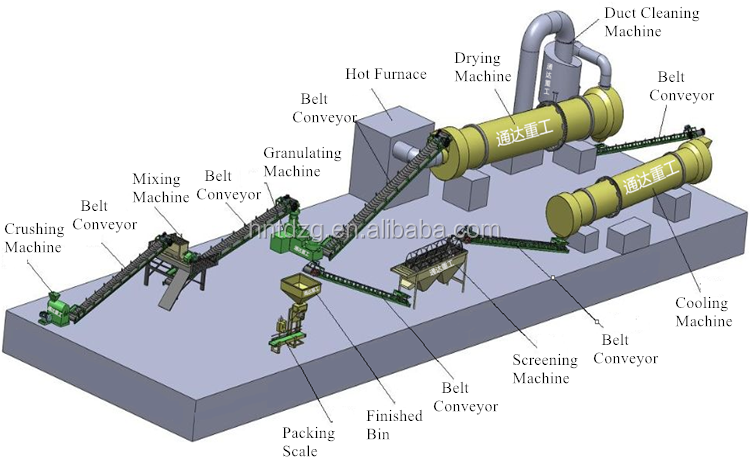

4. Organic fertilizer production line

In order to meet the needs of large-scale production of organic fertilizers,We are Henan Tongda Heavy Industry Technology Co., Ltd.Professional design and manufacture suitable for organic fertilizer production line and related machinerydifferent organic materials, has been a leader in this field in China.

| Annual output of small organic fertilizer plant (300 working days) | |||||

| 10,000 tons/year | 20,000 tons/year | 30,000 tons/year | |||

| 1.4 tons/hour | 2.8 tons/hour | 4.2 tons/hour | |||

| Annual output of medium-sized organic fertilizer plant | |||||

| 50,000 tons/year | 60,000 tons/year | 70,000 tons/year | 80,000 tons/year | 90,000 tons/year | 100,000 tons/year |

| 6.9 tons/hour | 8.3 tons/hour | 9.7 tons/hour | 11 tons/hour | 12.5 tons/hour | 13.8 tons/hour |

| Annual output of large organic fertilizer plant | |||||

| 150,000 tons/year | 200,000 tons/year | 250,000 tons/year | 300,000 tons/year | ||

| 20.8 tons/hour | 27.7 tons/hour | 34.7 tons/hour | 41.6 tons/hour | ||

5. Work process of organic fertilizer production line

- Fermentation process:

- Fermentation is the basic process of production. Moisture, temperature and time need to be strictly controlled. The compost turner is an organic fertilizer machine used to accelerate microbial fermentation and improve the quality of compost.

- Crushing process:

- Blocky materials should be pulverized after fermentation. Granulating substances by hand is difficult. In this way, you need to use a fertilizer shredder. We recommend customers to choose a high-moisture material grinder, which can grind semi-wet materials with high crushing efficiency.

- Granulation process:

- It is an important production process in the whole production line. According to different requirements, nutrients can be added. Dealing with spherical particles saves a lot of energy. Therefore, it is particularly important to choose a suitable organic fertilizer machine. The new organic fertilizer granulator is the most suitable machine.

- Drying process:

- After granulation, the granules need to be dried. Organic fertilizer moisture is reduced to 10%-40%. The rotary drum dryer is a kind of equipment for reducing the moisture content of the particles, which is suitable for the production of organic fertilizers.

- Cooling process:

- In order to ensure the quality, the granules should be cooled by means of a drum cooler after drying.

- Screening process:

- The organic fertilizer is unqualified during the production process. Drum type fertilizer screening machines are required to separate rejects from standards.

- Packaging process:

- The fertilizer packaging machine is used for packaging processed fertilizers. We can pack and bag the pellets using packaging machines. It can realize automatic and efficient packaging of products.

Ralavent Organic Fertilizer Production Line Products

-

Chicken manure granulator fertilizer/twin roll extrusion granulator fertilizer for sale

-

Industrial large capacity ZL rotary dry granulator granulator mixing granulator food powder processing production line

-

Ganulator Machine Chemicals, Minerals, Inorganic Powder Granulator Fertilizer Double Roll Press Machine Customized 15kw, 30kw CN; JIA 1t

-

Cat litter bentonite granulator/dry powder granulator

-

Organic fertilizer granulator

-

1000-1800 kg organic fertilizer bentonite pellet machine per hour

-

Fully automatic urea fertilizer plant/NPK fertilizer production line fertilizer machine

-

Disc Granulator Fertilizer Disc Granulator

-

High quality organic npk compound fertilizer making machine drum granulator for sale

-

npk fertilizer manufacturing machinery factory

Other Products

-

$480.00 - $500.00 / set

$480.00 - $500.00 / set -

$6300.00 / set

$6300.00 / set