Ganulator Machine Chemicals, Minerals, Inorganic Powder Granulator Fertilizer Double Roll Press Machine Customized 15kw, 30kw CN; JIA 1t

-

Supplier: Jiangsu Fuyi Machinery Technology Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Steven Shi -

Price: $100000.00 / 1 - 887 sets

$7000.00 / >=888 sets -

Min. Order: 1 set

| Health status: | new | Type of machine: | Granulator |

| hardness: | greater than 28N | Process flow: | Compact Dry Cold Shield Package |

| brand: | Fuyi | strength: | 15kw, 30kw |

| After-sales service provided: | On-site installation, commissioning and training | work method: | Double Roll Press |

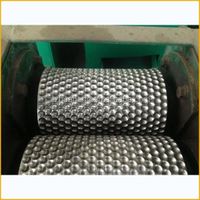

| Roller material: | Chrome molybdenum | Granular: | oblate/round/square |

| Origin: | Jiangsu, China | Recyclable: | Yes |

| payment terms: | L/C, T/T | Dimensions (L*W*H): | 1330*930*1400 |

| Certification: | East Asia Conference | Voltage: | custom made |

| Supply capacity: | 10 sets per month | Warranty: | 1 year |

| port: | Shanghai, Ningbo, Qingdao | Machine material: | carbon steel or stainless steel |

| Product Category: | fertilizer | granularity: | custom made |

| Production capacity: | 0.7-2 tons/hour/set | test sample: | Yes |

| Packaging Details: | 1. Big machine naked. 2. Spare parts are packed in wooden case. 3. If our customers have any special requirements, we will pack as required. | weight: | 1 ton |

DG series

Our company offers a wide range of high pressure granulator sizes, covering almost all requirements of customers. If your output is low, you can choose a small machine, if your output is high, you can choose one or more machines according to your requirements. Of course the granulation process is wet --The water content is between 2-5%.

main feature

1) The linear structure is simple, easy to install and maintain.

2) Pneumatic components, electrical components and operating components all adopt advanced world famous brand components.

3) High-pressure double cranks control mold opening and closing.

4) High degree of automation and intelligence, no pollution

5) Connect the pneumatic conveyor with a connector, which can be directly linked with the filling machine.

Forged from alloy steel.

The surface of the pressure roller can be plated with hard chrome for anti-rust and wear-resistant treatment.

special process heat treatment,

| DG200 | DG300 | |

| 15KW | 30KW | |

| Oblate 900-1300 kg/h, irregular shape 300-700 kg/h | Oblate 1600-2100 kg/h, irregular shape 900-1600 kg/h | |

| Special reducer with hard tooth surface | ||

| It is forged with alloy steel, heat-treated by a special process, and the surface of the pressure roller is plated with hard chromium for anti-rust and wear-resistant treatment. | ||

| Oblate 60-90%, irregular shape 30-60% | ||

| 3.8,4.2,4.8,5.5,6.0,6.5,8,10mm | ||

| Oblate, Irregular, Bar, Sliced | ||

| Inorganic material 2-5%, organic material 6-12% moisture | ||

| room temperature | ||

Fuyi granulation process layout

We can design different diagrams for different customers, we need to provide some basic information about their factory scale and how they want to place equipment to design the layout according to customers. Our goal is to make the process simpler, easier, more economical and more efficient.

Peripheral equipment of granulation line

In addition to the granulator, we can also provide a complete set of supporting equipment for the granulation process to help you better complete the granulation.

Such as mixers, bucket elevators, packaging machines, screening machines, drying/cooling machines, conveyors, control cabinets, etc.

60,000 tons/day ammonium sulfate granular fertilizer granulation line.

Our company has designed 32 sets of DG200 granulation process schemes for the St. Petersburg granulation project, realizing the plan of producing 60,000 tons of ammonium sulfate granules per year, and becoming one of the largest fertilizer suppliers in St. Petersburg.

Chemical powder granulation line

Our company designed 10 sets of DG200 granulation process solutions for the chemical plant project, which solved the problem of waste disposal.

European annual output of 150,000 tons of granular ammonium sulfate granulation line

our commitment

Since 2006, Fuyi designs and manufactures roller compactors and equipment for briquetting and compacting NPK fertilizers, powders, chemicals, minerals, etc. We are responsible for greenfield projects and existing factories. Our services include material testing of complete sets of granulation equipment or key equipment, process layout, engineering design and supply, installation and commissioning guidance, training.

In addition, the company manufactures and supplies drying equipment and dust collector equipment.

Extensive experience and top quality production facilities guarantee a smooth workflow from start to finish.

-

Chicken manure granulator fertilizer/twin roll extrusion granulator fertilizer for sale

-

Industrial large capacity ZL rotary dry granulator granulator mixing granulator food powder processing production line

-

Cat litter bentonite granulator/dry powder granulator

-

Organic fertilizer granulator

-

Latest Design Urea Fertilizer Production Equipment

-

1000-1800 kg organic fertilizer bentonite pellet machine per hour

-

Fully automatic urea fertilizer plant/NPK fertilizer production line fertilizer machine

-

Disc Granulator Fertilizer Disc Granulator

-

High quality organic npk compound fertilizer making machine drum granulator for sale

-

npk fertilizer manufacturing machinery factory