Picking Diecrtly Bamboo Wood Toothpick Stick Toothpick Making Machine in Nairobi, Kenya

-

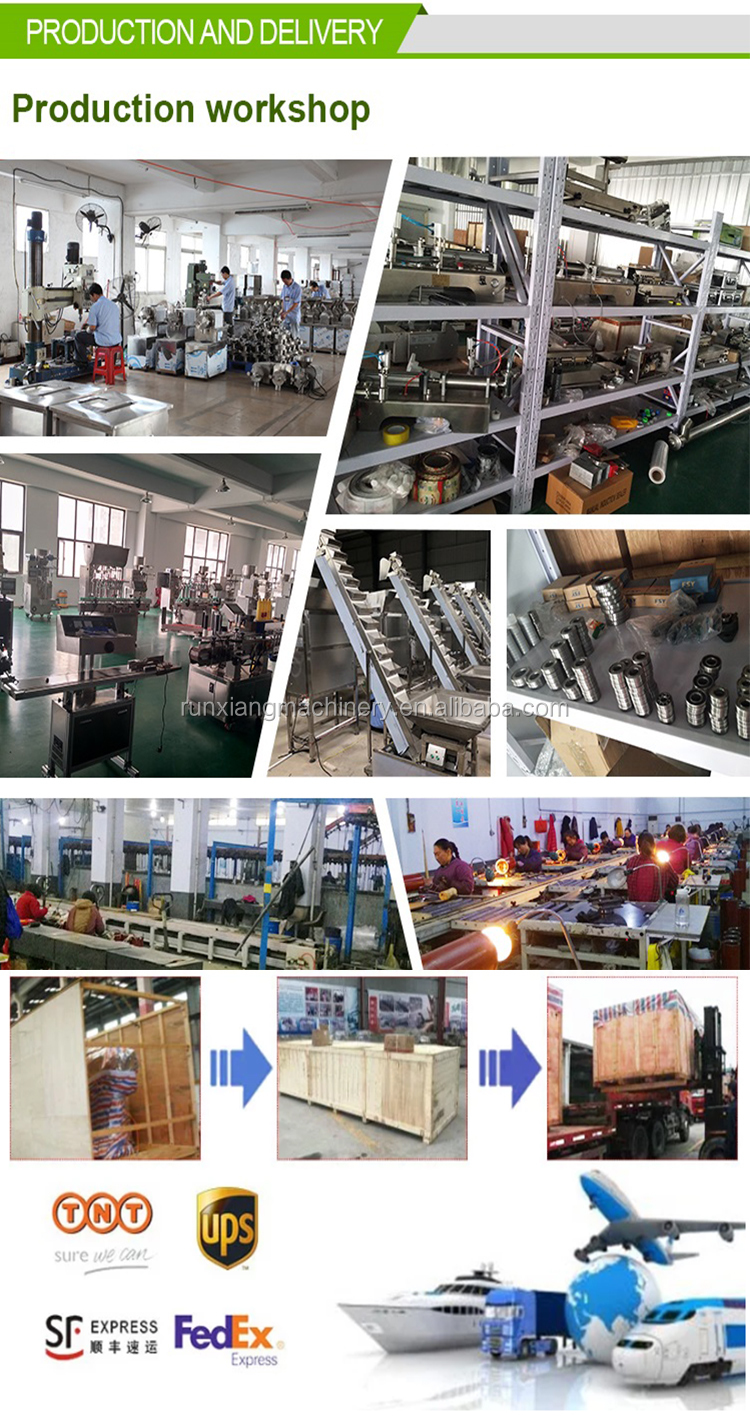

Supplier: Zhengzhou Runxiang Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Susan Miss -

Price: $1600.00 /set -

Min. Order: 1 set

| Video external inspection: | if | product name: | Toothpick production machine |

| place of origin; place of origin: | Other countries | Core components: | engine, motor |

| Showroom location: | Kenya | Packaging Details: | Export wooden boxes. |

| productivity: | 4800/8 hours | Marketing Type: | normal product |

| brand: | Runxiang | payment terms: | L/C,Western Union,T/T |

| weight: | 1850 | Name: | Bamboo Toothpick Machine |

| After-sales service provided: | Engineers can repair machinery overseas | Warranty: | 1.5 years |

| Core Components Warranty: | 2 years | Dimensions (L*W*H): | 5600*1350*1850mm |

| Applicable industries: | factory, farm | quality: | top floor |

| color: | adjustable | Health status: | new |

| Voltage: | 380v | strength: | 6.87kW |

| usage: | Making Bamboo Toothpick Sticks | pack: | wooden box |

| Packaging Preview: | Material: | carbon steel | |

| Mechanical test report: | if | Raw materials: | bamboo |

Bamboo and wood toothpick stick toothpick machine in Nairobi, Kenya

Traffic chat:

Raw bamboo--picking saw--cutting bamboo sticks--cutting the open pieces of fixed width into silk, bleaching, drying, cutting--fixing-length--polishing--tidying--removing defective sticks--nibs--removing Defective sign - packaging, storage (factory).

notes:Dimensions of the final bamboo toothpick, 2.2mm in diameter and 65mm in length, with sharp ends. capacity is800000 pieces/8 hours. We also match machines according to customer needs.

Toothpick processing machine description:

1. Bamboo saw machine: used to cut bamboo into a certain length.

2. Bamboo cutting machine: This machine is used to cut bamboo into strips.

3. Fixed-width slicer: used to set the width and thickness and remove knots, separate the green layer and the yellow layer, and ensure the surface quality of the processed material.

4. Bamboo strip shaping machine: This machine is used to make thick bamboo strips into thinner ones.

5. Bamboo stick sizing machine: special equipment for bamboo stick or wooden stick sizing and cutting, especially suitable for round stick sizing.

6. Bamboo toothpick cutting machine: bamboo toothpick length setting

7. Toothpick polishing machine: make the toothpick surface smoother.

8. Toothpick finishing machine: special equipment for finishing toothpicks. Through vibration, the irregular toothpicks are arranged to achieve the effect of packaging.

9. Toothpick sharpener: used to sharpen bamboo toothpicks.

10. Sharpening machine: used for sharpening.

Technical parameters of bamboo toothpick processing machine:

|

Do not. |

Name |

strength |

Weight (kg) |

Dimensions (mm) |

|

1 |

Bamboo Saw |

1.5 |

65 |

900*510*930 |

|

2 |

Bamboo dissection machine |

3.0 |

630 |

3000*850*1200 |

|

3 |

bomb flaker |

3.7 |

450 |

1460*660*1000 |

|

4 |

Bamboo wire setting machine |

9.1 |

450 |

1050*650*990 |

|

5 |

Bamboo wire sizing machine |

0.75 |

85 |

1500*650*990 |

|

6 |

polisher |

1.5 |

120 |

1050*1050*1200 |

|

7 |

Toothpick setting machine |

2.75 |

240 |

900*700*950 |

|

8 |

Toothpick finishing machine |

0.55 |

70 |

1050*900*850 |

|

9 |

Toothpick sharpening machine |

1.65 |

260 |

950*650*1050 |

|

10 |

knife sharpener |

0.55 |

50 |

370*330*720 |

|

notes:Dimensions of the final bamboo toothpick, 2.2mm in diameter and 65mm in length, with sharp ends. capacity is800000 pieces/8 hours. We also match machines according to customer needs.

|

||||

In addition to the semi-automatic toothpick stick production line, our company also hasThe production line of automatic bamboo cutting machine and toothpick machine is as follows:

|

phosphorusparameter name |

Specification Quantity |

Comment |

|

Number of knives |

8 sets |

|

|

Knifeouter diameter |

300mm |

|

|

Feed rate |

8-10 per minute |

|

|

Processing length |

1200-2100mm |

|

|

Machining diameter |

50-150mm |

|

|

host size |

5600*1350*1850mm |

Other specifications can be customized as required |

|

Feeder size |

2000*1250*1150mm |

|

|

total motor power |

6.87kW |

Main motor 5.5Kw, feeding 0.37Kw, tool box motor 1Kw |

|

weight |

1850 kg |

This machine adopts imported PLC system control and touch screen man-machine interface and photoelectric switch and proximity switch system control. Bamboo pipes of different sizes, equal thickness and equal length are manually placed on the automatic feeding rack of the equipment, and automatic feeding is adopted. The rack feeding device sends the bamboo tube to the top of the automatic feeding rack. After measuring the outer diameter of the bamboo tube with an electronic ruler, it will be automatically replaced with a bamboo piece of the required width, and then the automatic cutting machine will change the required cutter through the internal system instructions. The bamboo tube is automatically cut into the material of the automatic bamboo cutting machine, the bamboo tube is clamped by the clamping arm device that automatically centers the material, and then the collision bowl is automatically pushed to the cutting knife to cut the bamboo tube and cut the bamboo tube into bamboo slices. After that, the bamboo chips are sent to the bamboo chip receiving rack through the automatic discharging device.

We also offer a complete line for making bamboo toothpicks and bamboo sticks.

FAQ

Q: Can you send me the video to see how the machine works?

A: Of course, we have made videos for each machine and uploaded to Youtube.

Q: How do I know your machine is working well?

A: Before shipment, we will test the working state of the machine for you.

Q: How do I know your machine is designed for my product?

A: You can send us a sample of your product and we will test it on the machine.

Q: Do you have CE certificate?

A: Each machine has CE certificate.

Your satisfaction is our honor!

-

Toothpick Bamboo Automatic Toothpick BBQ Stick Machine Bamboo Kebab Making Machine for Sale

-

Hot selling toothpick making machine and making machine bamboo toothpick wooden toothpick making machine

-

Bamboo toothpick making machine fully automatic bamboo toothpick making machine toothpick production line

-

Latest Design Different Capacity Factory Price Bamboo Splitting Machine

-

incense stick machine price incense stick machine toothpick machine

-

wooden toothpick making machine for sale cinnamon toothpick making machine made in china low cost

-

Wooden round bar toothpick sharpener from China supplier UT Machinery

-

Automatic High Speed Bamboo Combination Drawing Machine

-

Complete Bamboo Toothpick Production Line Machine BBQ Stick Making Machine Wooden Toothpick Making Machine

-

China toothpick factory produces BBQ sticks bamboo skewer machine for sale

Other Products

-

$1180.00 - $1290.00 / set

$1180.00 - $1290.00 / set -

$560.00 / set

$560.00 / set -

$1090.00 - $1120.00 / set

$1090.00 - $1120.00 / set -

$8000.00 - $9160.00 / set

$8000.00 - $9160.00 / set -

$5500.00 - $10000.00 / set

$5500.00 - $10000.00 / set -

$4890.00 / set

$4890.00 / set -

$550.00 / set

$550.00 / set -

$2000.00 / set

$2000.00 / set -

$980.00 / set

$980.00 / set -

$2000.00 / set

$2000.00 / set