Wooden round bar toothpick sharpener from China supplier UT Machinery

-

Supplier: Gongyi UT Machinery Trade Co., Ltd. -

Region: Henan, China -

Contact: Mr Orion Chai -

Price: $1980.00 / 1 - 4 sets

$1880.00 / >=5 sets -

Min. Order: 1 set

| Name: | chopsticks machine | place of origin; place of origin: | Henan, China |

| Finished product: | Toothpicks chopsticks skewers barbecue sticks | Toothpick shape: | Single or double pointed toothpicks |

| Packaging Details: | Chopsticks Machine WOODEN BOX | After Warranty Service: | Video technical support |

| Craft materials: | wet bamboo | Core components: | engine, gear |

| port: | Qingdao Port, Ningbo Port, Shanghai Port, Tianjin Port | application: | Bamboo and Wood Toothpick Craft |

| Supply capacity: | 10 sets per week | Warranty: | one year |

| weight: | 2.5 tons | Material: | ban bum |

| capacity: | 80000 pecs/8 hours | Video external inspection: | if |

| weight: | 2330 | Function: | Tooth processing |

| Core Components Warranty: | 2 years | Marketing Type: | Hot Products of 2021 |

| Showroom location: | Vietnam, Philippines, Indonesia, Pakistan, Thailand | Dimensions (L*W*H): | 1250×700×500MM |

| Mechanical test report: | if | Applicable industries: | Manufacturing, Home, Energy & Mining |

| Voltage: | 380V | brand: | Utah |

| strength: | 5.5KW | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Health status: | new |

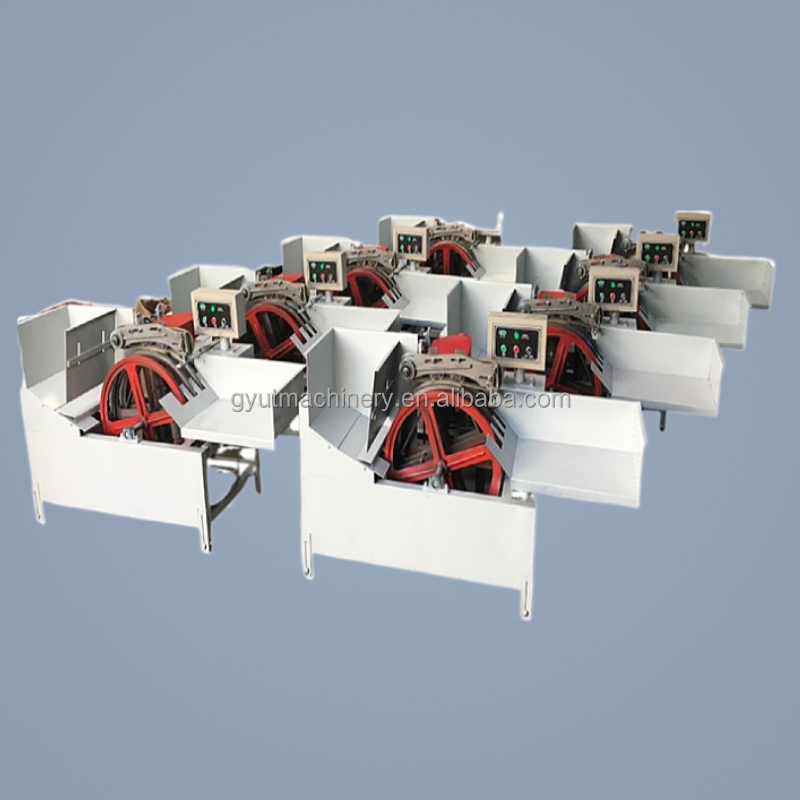

Commercial automatic bamboo stick machine/bamboo toothpick making machine

BBQ Stick End Sharpener:

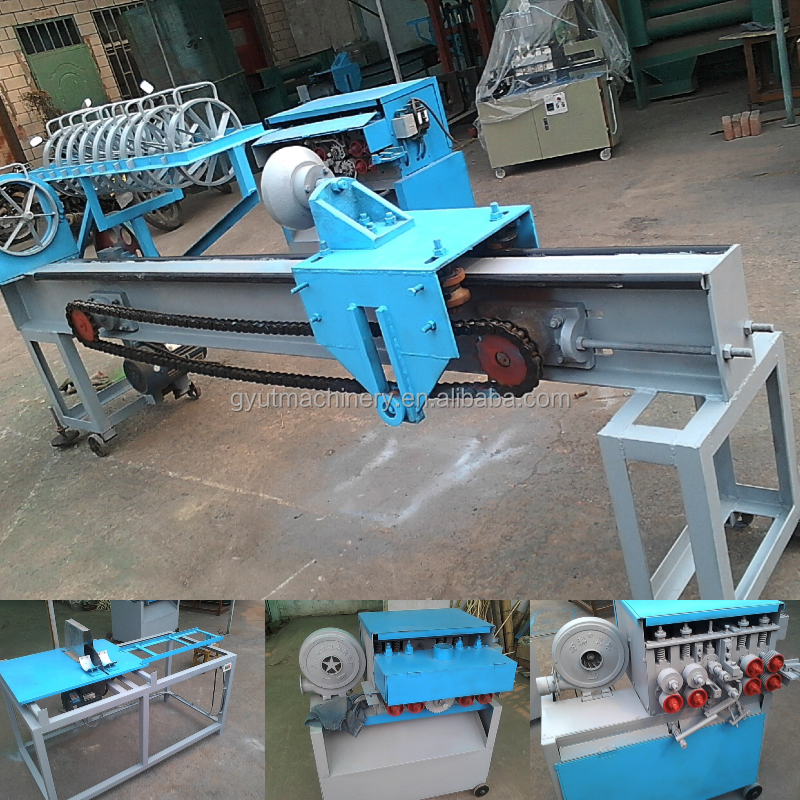

The working process of the bamboo toothpick machine:

1. Sawing machine: As the first step of making toothpicks, you can use a knife with a diameter of 400mm and a power of 1.5kw to cut the long bamboo into several short sections.

2. Bamboo dissection machine: The bamboo is placed in the center of the cutter head, and the bamboo is opened by the impact of the cutter head when working. The width of the split bamboo pieces is controlled by adjusting the blade density. In addition, the machine comes with 10 knives.

3. Wood Slitting Machine: Bamboo is fed into the machine by rotating wheels. The cutter in the middle of the machine slices the bamboo into thin slices. We can also provide machines to split the wood, depending on the customer's requirements.

4. Bamboo silk setting machine: The wood or bamboo is fed into the machine by rotating wheels, which divide them into finer pieces for easy subsequent processing.

5. Bamboo wire sizing machine: Used to cut bamboo or wood silk into shorter pieces. There are baffles inside the equipment, and the baffles can be adjusted to control the length of the cut.

6. Toothpick filament sizing machine: It is used to cut bamboo wire or wood wire into toothpick length, with low noise and low energy consumption, only one person is required to operate.

7. Polishing machine: The machine shakes to increase the friction between these sticks, thus polishing the surface.

8. Toothpick Sorter: There are grids that fit the toothpick size. The toothpick swings with the body to facilitate the next processing.

9. Knife Sharpener: Put the wooden stick into the machine, the wooden stick enters the tray and rotates, and the belt on the upper end of the tray drives the wooden stick to perform autobiography. Sharpen the knife after grinding.

10. Tool sharpener: The sharpener is protected by a protective cover, which is safe and reliable. The blade is made of stainless steel, which is sharp and durable, and easy to operate.

|

thing |

Motor(kw) |

Weight (kg) |

|

Bamboo Saw |

2.2 |

65 |

|

Bamboo dissection machine |

3.0 |

530 |

|

Bamboo Slicer |

11.1 |

780 |

|

Bamboo Silicone |

1.1 |

160 |

|

Bamboo sizing machine |

1.5 |

120 |

|

Bamboo chopsticks forming machine |

4*0.75+1.1 |

600 |

|

chopsticks sharpener |

0.75 |

600 |

|

polisher |

2.2 |

230 |

|

knife sharpener |

0.55 |

50 |

1. For the above products, use the original bamboo - picking saw - open bamboo - interrupt the full opening, wire drawing, bleaching,drying, tailoring,Grinding, sorting, sharpening, packaging.

2. More than 10 sets form a production line, producing two sharp toothpicks, 800,000 toothpicks in 8 hours, about100Kilogram. requires manipulationThere are 4 or 6 employees, and the industrial electricity is 380 volts.9 machines added, production doubled to 1.6 million units

3. Generally, per 100 kg of fresh bamboo (wet), 100,000-130,000 toothpicks with a diameter of 2.0 mm and a length of 65 mm can be produced, and 13-16 kg of dry finished teeth can be produced.

-

Toothpick Bamboo Automatic Toothpick BBQ Stick Machine Bamboo Kebab Making Machine for Sale

-

Hot selling toothpick making machine and making machine bamboo toothpick wooden toothpick making machine

-

Bamboo toothpick making machine fully automatic bamboo toothpick making machine toothpick production line

-

Latest Design Different Capacity Factory Price Bamboo Splitting Machine

-

incense stick machine price incense stick machine toothpick machine

-

wooden toothpick making machine for sale cinnamon toothpick making machine made in china low cost

-

Automatic High Speed Bamboo Combination Drawing Machine

-

Complete Bamboo Toothpick Production Line Machine BBQ Stick Making Machine Wooden Toothpick Making Machine

-

China toothpick factory produces BBQ sticks bamboo skewer machine for sale

-

Picking Diecrtly Bamboo Wood Toothpick Stick Toothpick Making Machine in Nairobi, Kenya

Other Products

-

$396.30 / set

$396.30 / set