Industrial machine for production of disposable bamboo sticks / set of bamboo sticks

-

Supplier: Zhengzhou Runxiang Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Susan Miss -

Price: $10000.00 / 1 - 9 sets

$9000.00 / 10 - 49 sets

$5500.00 / >=50 sets -

Min. Order: 1 set

Product details

| Core Components Warranty: | 2 years | Marketing Type: | New Products 2020 |

| feature: | high efficiency | port: | Qingdao |

| Packaging Preview: | Key words: | chopsticks machine | |

| place of origin; place of origin: | China | Supply capacity: | 500 sets per month |

| After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Minimum order quantity: | 1 |

| After-sales service provided: | Provide video, video technical support, online support, on-site installation and commissioning training, on-site maintenance and repair services | Warranty: | 1 year |

| capacity: | 100000,8 pairs | Voltage: | 380v |

| product: | chopsticks machine | pack: | Wooden packing |

| payment terms: | L/C,Western Union,D/P,D/A,T/T | Shipping method: | Express/Sea/Air |

| Health status: | new | usage: | Hotel homepage use |

| strength: | 1.5 | weight: | 210 kg |

| Local service location: | not any | Mechanical test report: | if |

| delivery time: | 15-25 working days | Showroom location: | not any |

| Applicable industries: | Hotels, Apparel Stores, Building Materials Stores, Food and Beverage Plants, Farms, Restaurants, Home, Retail, Food Stores, Printing Stores, Energy and Mining, Food and Beverage Stores | Auto grade: | semi-automatic |

| brand: | Runxiang | Dimensions (L*W*H): | 1680*880*1090mm |

| Core components: | motor | Video external inspection: | if |

| Packaging Details: | export wooden box |

Product Description

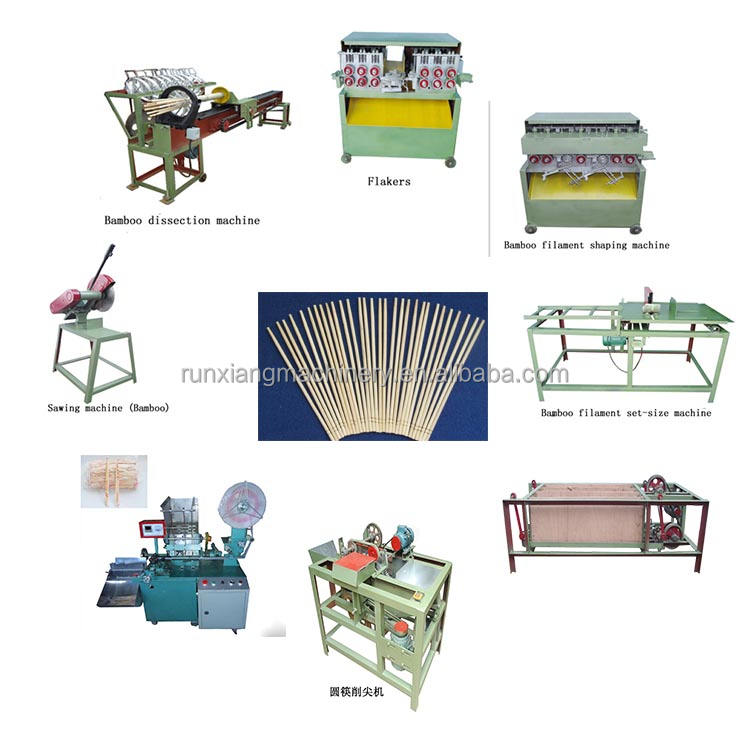

Size: Φ4.5~Φ5.0, L190mm

Capacity: 3800~4500 pairs.

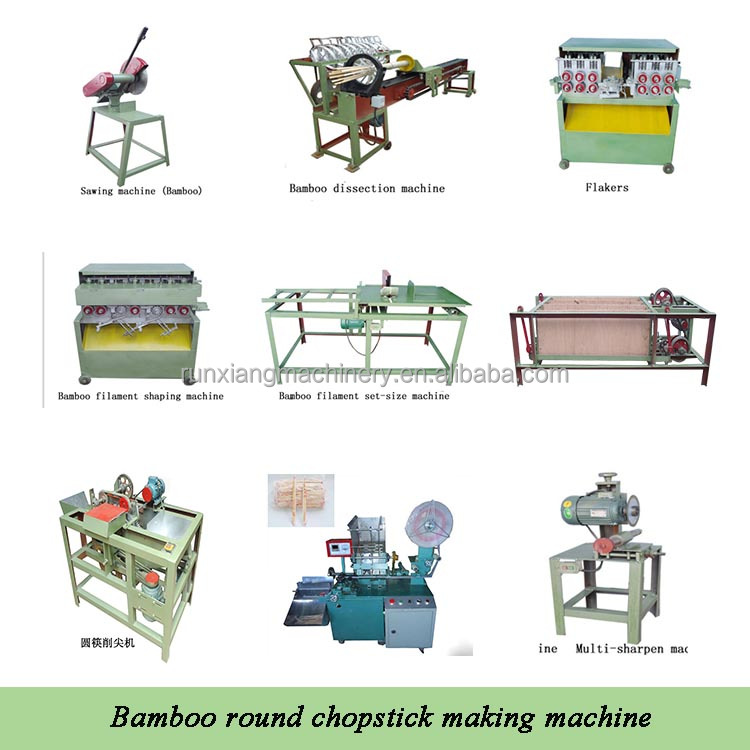

Number of machines: 7

Capacity: 3800~4500 pairs.

Number of machines: 7

1. The above 7 sets can produce 100,000 pairs in 8 hours. Five to seven mechanics are required, regardless of gender. The power supply is 380V industrial power supply, and the actual power consumption in normal production is about 12 kWh/hour.

2. Under normal circumstances, each 100 kg of fresh (wet) bamboo can produce 3800 to 4500 pairs of Φ4.5~Φ5.0 long 190mm round chopsticks

3. Mechanical instructions, bamboo bleaching, mildew-proof, moth-proof methods and random accessories (including wearing parts, special accessories and special tools) are listed separately and are not priced.

working principle

The technological process of the above products:

Raw bamboo--retrieving and sawing--splitting bamboo strips--making agglomerates of fixed width into filaments--

Bleaching--drying--cutting--polishing--pick up debris--sharpen a knife--pick up debris--

Packaging - Storage (factory).

Raw bamboo--retrieving and sawing--splitting bamboo strips--making agglomerates of fixed width into filaments--

Bleaching--drying--cutting--polishing--pick up debris--sharpen a knife--pick up debris--

Packaging - Storage (factory).

Specification

Do not. | Name | Model | motor | size | weight | ||

1 | sawing machine | ZJ-791 | 1.5 | 125×50×105 | 58 | The specifications of the bamboo chopsticks ring are: 4.5mm~ΦΦ6mm, and the length is: 190mm~240mm. | |

2 | dissection machine | ZJ-388 | 4 | 310×70×125 | 650 | ||

3 | peeling machine | ZJ-275 | 2.2 1.1 | 130×65×105 | 310 | ||

4 | Filament forming machine | ZJ-144 | 4.0×2 1.1 | 110×65×110 | 415 | ||

5 | setting machine | ZJ-741 | 0.75 | 110×66×88 | 80 | ||

6 | polisher | TJ-543 | 2.2 | 215×100×85 | 300 | ||

7 | Bamboo round chopsticks cutting machine | TJ-818 | 1.1 0.37×2 | 140×80×100 | 280 | ||

8 | multi-mill | TJ-803 | 0.37 | 75×50×95 | 65 | ||

9 | chopsticks packaging machine | TJ-821 | 0.45 | 150×60×130 | 100 | ||

total | 23.51 | 10.66CBM | 2258 | ||||

Features

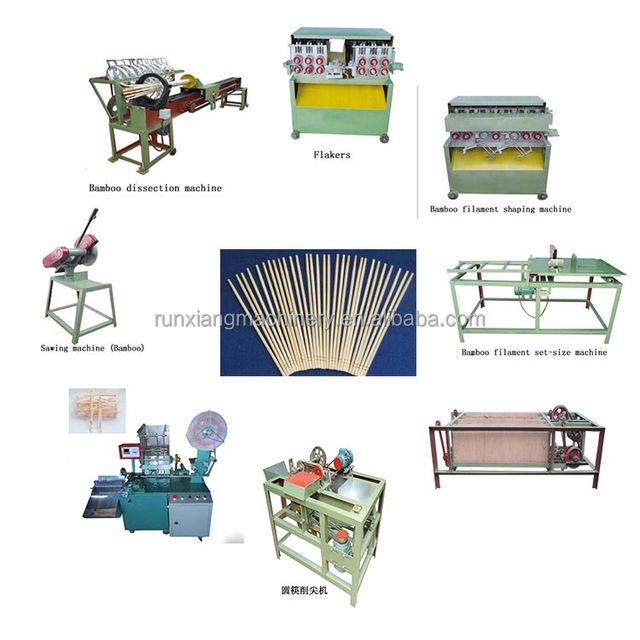

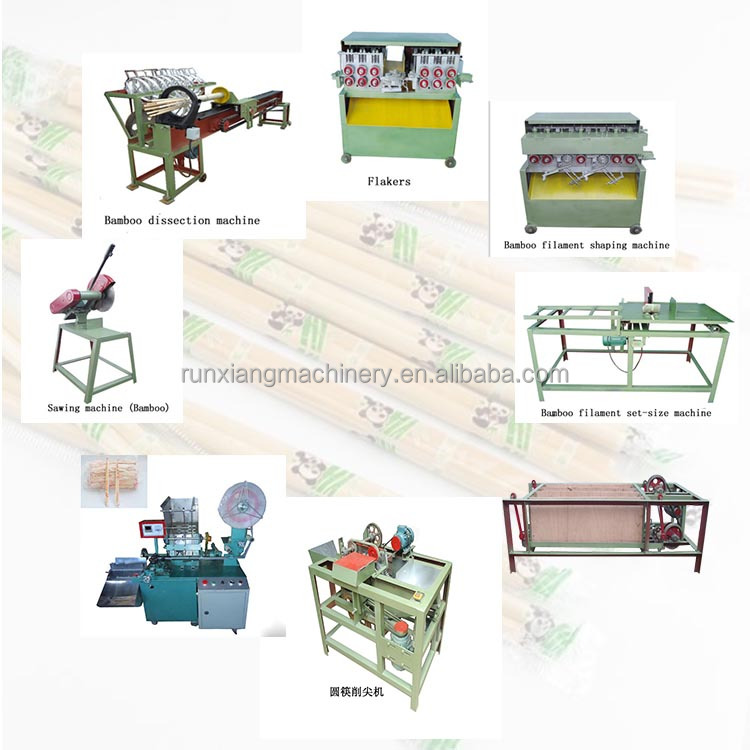

Bamboo chopsticks machine is used to produce bamboo chopsticks and consists of 7 machines. The machine list is as follows:

1. Fresh bamboo saw machine: Cut fresh bamboo into a certain size.

2. Bamboo splitting machine/dissecting machine: split bamboo into pieces.

3. Bamboo slicer: fix the width of the bamboo slices and flatten the bamboo slices.

4. Bamboo silk machine

5. Bamboo wire sizing machine: Cut the bamboo wire into certain strips.

6. Bamboo polishing machine: Polish the chopsticks to make the surface smooth.

7. Bamboo chopsticks sharpening knife

8. Bamboo multifunctional knife sharpener: sharpening or sharpening.

1. Fresh bamboo saw machine: Cut fresh bamboo into a certain size.

2. Bamboo splitting machine/dissecting machine: split bamboo into pieces.

3. Bamboo slicer: fix the width of the bamboo slices and flatten the bamboo slices.

4. Bamboo silk machine

5. Bamboo wire sizing machine: Cut the bamboo wire into certain strips.

6. Bamboo polishing machine: Polish the chopsticks to make the surface smooth.

7. Bamboo chopsticks sharpening knife

8. Bamboo multifunctional knife sharpener: sharpening or sharpening.

application

1. Prepare raw bamboo: it needs to be fresh or grown for more than 3 years. Because if the raw material is dry, it is not good for the machine.

2. Use the machine to make the wood step by step.

3. Flakes are used.

4. Filament is completed. It needs to die! You can choose to use the dryer or dry in a sunny location.

5. The last chopstick is ready. It can be packed.

VIEW MORE

You may like

-

Wooden bamboo chopsticks production line/full set of wooden chopsticks making machine

-

Bamboo Round Toothpick Chopsticks Production Line BBQ Incense Stick Making Machine

-

wooden sticks deburring machine/polishing machine/forming machine

-

Wooden or Bamboo Chopstick Maker/Chopstick Maker

-

Bamboo Round Stick Production Line Disposable Wooden Chopsticks Processing Machine Making Chopsticks

-

Bamboo Sticks Packing Machine, Round Sticks Packing Machine, Sticks Packing Machine

-

Wooden chopsticks machine bamboo chopsticks machine tableware factory

-

In 2023, Alibaba's hot-selling product Shanghai Gliwu chopsticks machine

-

Disposable Bamboo Twin Chopsticks Making Machine Production Line

-

UDDN-Bamboo Chopsticks Making Machine Automatic Bamboo Chopsticks Maker Line

Other Products

-

$1180.00 - $1290.00 / set

$1180.00 - $1290.00 / set -

$560.00 / set

$560.00 / set -

$1090.00 - $1120.00 / set

$1090.00 - $1120.00 / set -

$8000.00 - $9160.00 / set

$8000.00 - $9160.00 / set -

$1600.00 / set

$1600.00 / set -

$4890.00 / set

$4890.00 / set -

$550.00 / set

$550.00 / set -

$2000.00 / set

$2000.00 / set -

$980.00 / set

$980.00 / set -

$2000.00 / set

$2000.00 / set

Related Search

machines for production of sugar

machine for production of wires

machines for production of nails

machin for product of screw suppliers

counting machine for products

equipment for production of balancing weights suppliers

hdpe for production of plastic bags

machines for casting of gold

machines for bags of carton

industrial machines for dryers