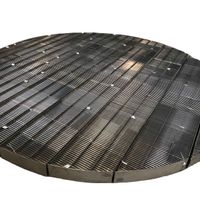

Tower Internals Metal Liquid Distributor

-

Supplier: Jiangxi Eloong Environmental Technology Co., Ltd. -

Region: Jiangxi, China -

Contact: Mr nina Xu -

Price: $150.00 /set -

Min. Order: 1 set

| Brand Name: | Eloong; | Filter rate: | 99%; |

| Port: | Shanghai,Shenzhen; | Applicable Industries: | Manufacturing Plant; |

| Certification: | ISO9001:2008; | Mesh Type: | SP/DP/HP; |

| Application: | Mass Transfer; | Brand Name: | Eloong; |

| Material: | Metal; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,PAYPAL; |

| Place of Origin: | Jiangxi; | Package: | Wooden box; |

| Diameter: | Customized; | Install Type: | Up/Down; |

| Supply Ability: | 300 Cubic Meter/Cubic Meters per Month 500; | Packaging Detail: | Liquid Distributor For Tower Internals Packing method include: wooden box or according to customers' requirements.; |

| Height: | Customized; |

Liquid Distributor For Tower Internals

Welcome to JiangXi Eloong Environmental Technology Co.,Ltd

What we capable with:

- 18 years involved the petrochemical packing

- Automatic equipment for whole production line

- Created 'plastic corrugated gauze structured packing' for the industry with 100% RD property

- Stablely supporting leading company like JFE Japan / MTE British ...

- With own independent QC system

- Serviced over 200 projects

Liquid distributor

In order to reduce the amplification effect caused by the poor distribution of the liquid and to fully utilize the efficiency of the filler, it is necessary to install a liquid distributor in the packed tower to evenly distribute the liquid on top of the packing layer.

The quality of the initial distribution of the liquid not only affects the mass transfer efficiency of the packing, but also affects the operational flexibility of the packing.

Therefore, the liquid distributor is a key internal part in the packed tower, and there are many types of distributors. The selection basis mainly includes distribution quality, operation flexibility, treatment volume, gas resistance, and levelness.

Types including:

According to the distributor fluid power: Gravity type liquid distributor (hole type, weir type, pressure type, spray type, porous tubular type.

According to the shape of the distributor: tube type, double-layer tube, trough type, disc type, impact type, nozzle type, pagoda type, lotus type, combined type, etc.

According to the form of the liquid leaving the distributor: pore flow type, overflow type.

According to the number of times the liquid is distributed: single-stage, multi-level.

According to the combination of distributors: tube trough, hole trough, trough pan.

The trough distributor is mostly used for packed towers with larger diameters. Such a distributor is less prone to blockage and has less resistance to gas, but requires a higher level of installation, especially when the liquid load is small.

The porous tubular distributor can adapt to the large flow fluctuation of the remains, and the installation level is not high, and the resistance to the gas is also small. However, since the small holes in the pipe wall are easily clogged, the dispersed liquid must be clean.

The orifice type distributor is similar to that of the trough distributor, but it has a large resistance to gas and is only suitable for occasions where the gas load is not too large.

There are also a variety of spray distributors that are commonly used (such as showerheads), especially in small packed towers. The disadvantage of this type of distributor is that it generates more entrainment of the liquid when the amount of gas is large.

Effect

The function of the liquid distributor is to uniformly distribute or redistribute the liquid on the top or a certain height of the packing to improve the effective surface of mass transfer and heat transfer, improve the phase contact, and thereby improve the efficiency of the tower.

Below is liquid distributor project we support in world wide

Company info

Eloong import & export Co.,Ltd mainly handling the petrochemical packing products with main series like : Plastic / Metal / Ceramic random packing , Tower structured packing , Water treatment packing , Tower internals , Porcelain Molecular Sieve / Ceramic Honeycomb / Catalyst Media items , Mold tooling & etc.

Running with 100% automatic production machine.

Equipping with R&D center , Mold tooling house, Tunnel kiln , bio proving ground .

Customer Visiting

We professionally providing full size of PLASTIC CORRUGATED PLATE PACKING, Visiting customers worldwide accredited the quality and specially the fast delivery which occurred by the automatic production .

Since the 3th year of the export , We constantly attending the fairs like ACHEMA Germany , ICIF , APCChE , Canton Fair & etc. Building up the stable cooperation relationship with the industry’s leading company like JFE Japan, MTE British . Hoping you will be our partner in next .

Equipment

Eloong company own the first & the only 100% automatic production line in petrochemical packing industry of the whole China mainland . Not only the pall ring , But full series of the products can be automatic production . Related equipment like Auto material conveyance system , refrigeration circulation system , CNC , EDM , manipulator & etc all located well .

Research and Development

Our R&D center proudly contribute the item ‘ Plastic Corrugated Gauze Structured Packing ’ to the market which now widely used in worldwide with 100% industrial property . Meanwhile , To get a better application performance . We also expanded it with ceramic & water treatment related Tunnel kiln, bio proving ground . The systematic mold tooling dept. allowed us to service our customer in design / drawing / molding and every R&D related processes .

Packing and Delivery

| Packing | Delivery |

| 1. Woven bag packing | 1. Less than 5cbm / 1-2 days with stock |

| 2. In ton bag packing | 2. Less than 20GP / 3-5 days |

| 3. On pallet packing | 3. A 20GP / 5-7 days |

| 4. In wooden case packing | 4. A 40GP / 7-9 days |

| 5. In carton packing | 5. A 40HQ / 9-10 days |

| 6. In steel drum packing or under your require |

1.Is your company a factory?

Yes, We are the professional manufacturer over 18 years, and have 13 years export experience.

2.Can you provide free sample?

Yes, sample can be free within 0.5kg.

3.What’s your MOQ?

1 cubic meter

4.Can you delivery on time according to the above short delivery time?

Of course we can, we have fully automatic mechanized products for our each product, daily production reach 100 cubic meters, we do promise delivery to you at the rocket speed.

We are ready and expecting to help you fulfill all the requirement !

We sincerely hope to establish the long-term relationship. Welcome for your inquiry

-

Marine Scrubber Vane Demister Droplet Separator Demister

-

1000mm stainless steel elliptical hemispherical conical quasi-spherical head pressure vessel cans

-

China new design sealed top loading arm and fmc loading arm supplier

-

Floor-mounted loading control electronic cabinet with railcar top loading arms for tank farms

-

Manufacturers supply the liquid distributor through the stainless steel liquid distributor

-

Ammonia distillation unit sieve plate stainless steel perforated sieve plate

-

Protect Mail Material Inflatable Airbag Bubble Column Packaging For Cosmetics

-

2022 High-efficiency column internals trough liquid distributor

-

Rail tank car, road tank car upper and lower loading arm

-

York Mesh 431, 421, 326 Supply, Wire Mesh 2205 Mist Eliminator Factory Supplier

Other Products

-

$200.00 / set

$200.00 / set