5L supercritical co2 essential oil extractor/co2 extraction machine for sale

-

Supplier: Suzhou Pharma Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Alan Wang -

Price: $25600.00 /set -

Min. Order: 1 set

| Function: | Extract Oil; | Material: | Stainless Steel; |

| Usage: | Pharmacy/Food industry; | Process: | Co2 extraction; |

| Type: | Extractor; | Weight: | 1000kg; |

| Extraction Type: | Super Critical CO2 Fluid Extraction; | Single gross weight: | 800 KG; |

| Single volume: | 9 cm; | Brand Name: | PHARMA; |

| Place of Origin: | Jiangsu China (Mainland); | Size: | According to size; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Name: | 5L supercritical co2 essential oil extractor; |

| Application: | Powder; | Selling Units: | Single item; |

| Capacity: | 1~3000 Option; | Package Type: | WOODEN CASE; |

| Delivery Detail: | 0 days after payment; | Certification: | ISO CE; |

5L supercritical co2 essential oil extractor/co2 extraction machine for sale

Model | SH120-50-05 |

Max. extract pressure | 50MPa |

Single extract cylinder volume | 5L |

Extraction temperature | Room temp – 75℃ |

Max. flow | 0-50L/h(adjustable) |

Kettle material | 1Cr18Ni9Ti |

Separation kettle volume | 2000ml+1000ml |

Separation kettle pressure | 30MPa |

CO2 store tank volume | 4L |

CO2 store tank pressure | 16MPa |

Dimension | 3700×2500×2800mm |

Weight | 1350KG(Approximate) |

![]()

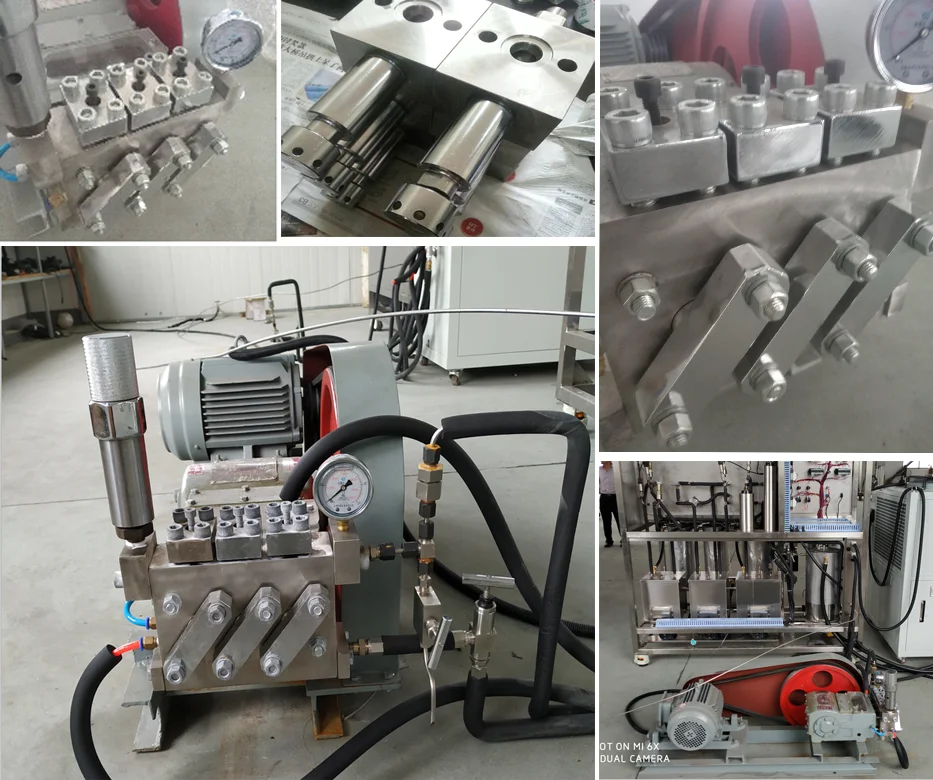

For the supercritical extraction machine-

1.CO2 Pumb 2. Cooling System 3.Machine Valve 4.50MPA Pressure

These are 3 most important parts that can directly tell by the machine quality and also influnce

the machine production capacity and service time a lot.

CO2 Pumb

Our CO2 Pumb adopted best quality in the market which used all Stainless steel inner cavity and 3 all ceramic stick to reduce the noise greatly and also will keep the machine work stably in the long time running.

The working pressure can achieve 50 Mpa instead of the normal pumb 40 Mpa.The using life is the normal pumb 5~10times.Max pressure can achieve 65 Mpa to protect the pumb safe.And the cost is at least 3-5 times of normal one.

The normal low quality pumb of others pressure only 40Mpa.Machine adopted low quality Iron Steel.The pumb stick is ceramic layer stick or steel stick which is easy to wear and leak CO2.Not safe to use for long time due to the low safety pressure once the pressure is high easy to occur accident .The using life only 5-15 months.Beyond the tie the abrasion will more serious and start to leak CO2.

Once the pumb broke is very difficult to repair and the replace and workers installation fees are extremely high about at least USD 6,000

High efficiency Air-cooled type make CO2 tank low down in the suitable temperature and easy to running.Inner with high quality compressor

Cooling System

Machine with Environmental refrigerant meet the environmental standard and high heat exchange efficiency.

Low efficiency heat exchange.Low cooling power and the actual working is far below the machine marked.Low down the production speed.

The bad quality cooling refrigerant easy to leak cause pollution and worker injured.Inner compressor fan is low strength once damage can only replace the compressor or the cooling system.Cause great loss.

Machine Valve

The Pressure Valve are the important part of the machine.Directly influence the production process.

And this is the easy damage part.The using frequency is the highest in production.So this part we used the best brand in the market.This is the 'USA' brand TESCOM the valve brought the most reliable performance.

Valve of poor quality plastic handle when in the low temperature easy to break and not accurately to control the flow.

And some factories even use the valve no any production just directly contact with the metal.This will cause work accident very possibly.

50MPA Pressure(extraction tank and pipe design)

Our kettle all adpoted SUS 304 and we caiculate the machine size as the inner material capacity instead of the kettle volume there are 25~30% size difference.

All our kettle used the screw connection instead of the welding.thickness and weight of kettle also are much more than the others.Even though we incrase lots of cost but this can protect our customers production safe more.

All the pipes are covered with insulation cotton to avoid the temperature change form condensate water damage machine and low down the noise greatly.Our workers all have more than 10 years production experience.

And our machine is designed only need connect 6 quickly interface pipes.This is easy and save at least USD 6,000-10,000 engineer abroad installation fees.And all body use SUS 304 easy to clean and not easy to rust.All the parts adopted advanced design to low down the power loss and increase the production speed.

Packing

1.What does PHARMA need from me to quote a price?

a).Raw material

b).Production capacity per batch,we supply 0.5L~200L machine for you,big capacity of machine can be customized according to your request for your request.

2.What material can you process with this machine?

Our CO2 extract machine is widely used in extracting hemp oil, wheat embryo oil,fish oil,tobacco essential oil,Arteannuin,Sundrops oil,Gingerol,Pepper haematochrome,Hops oil etc.

3.What is the machine material you use?

Stainless steel 304.

4.What is the highest pressure does your machine can suffer?

50Mpa.Our standard design is 40Mpa..

5.Does the CO2 can be reused?

YES. CO2 can be used in circulation.

6.Does you machine can work under the conditions of supercritical and subcritical?

No,it can only work at supercritical state.

7.Can we do extraction test before purchasing?

Of course,we can do extraction test with your raw material and send you videos and pictures

for your reference.

8.Do you have machine in stock?

No,every machine is customized according to your order.

9.How long does it take to produce the machine once I place my order ?

The Supercritical CO2 extract machine’ process flow is complex.Generally it takes about 60 workdays to Produce.We are responsible for the quality of machine our customers.Every procedure and details has to be inspected strictly.

10.How will my order be packed, can you provide the installation service?

Plywood case. And we will assemble and test the machine before packing.

Installation:We will send English manual after your purchase. If customer need, we will send one engineer for assembling and training for workers. USD80 per person per day, food, accommodation and air-ticket will be on clients.

-

Pharmaland Automatic Empty Capsule Separator Drug Separation and Screening Machine

-

Herbs, Tea Bag Powder, Sugar Salt Spice Chili Grinder Grinder

-

Dingli BY-300 commercial industrial automatic sugar coating machine

-

Plaster of Paris bandage production line

-

Professional Wholesale Custom Portable Carbon Dioxide Extractor for Fresh Hemp Terpene Extraction

-

SZS 200 tablet dust collector is suitable for all kinds of tablet polishing machines

-

Simple and innovative product fresh herbal terpenoid extraction small supercritical carbon dioxide extractor

-

Desktop automatic tablet defoaming machine defoaming machine defoaming machine price

-

Pharmaceutical chemical machinery for stainless steel chemical crystallization reactor

-

High-quality energy-saving No. 0 filling machine spot

Other Products

-

$13500.00 / set

$13500.00 / set -

$200.00 / square meter

$200.00 / square meter