best price customized Explosion-Proof scattered quantitative loading control instruments for oil gas chemical control system

-

Supplier: Hubei Hongyi Electronic&Technology Co., Ltd. -

Region: Hubei, China -

Contact: Mr Alexander Wu -

Price: $1999.00 / 1 - 9 sets

$499.00 / >=10 sets -

Min. Order: 1 set

| Product name: | batch controller; | Video outgoing-inspection: | Provided; |

| Dimension(L*W*H): | 300 x 400 x 150; | Machinery Test Report: | Provided; |

| Marketing Type: | New Product 2019; | Place of Origin: | Hubei, China; |

| After-sales Service: | Engineers available to service machinery overseas; | Working temperature: | -40℃~70℃; |

| Supply Ability: | 1000 Sets per Month; | Material: | SS304; |

| Key Selling Points: | best price,high quality; | Warranty: | 1.5 year,1 Year; |

| Applicable Industries: | petrochemical; | Condition: | New; |

| Packaging Detail: | wooden case; | After Warranty Service: | Video technical support,Online support; |

| Local Service Location: | None; | color: | as require; |

| Showroom Location: | None; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Package Preview: | ; | Power supply: | 110~240VAC,2A,50Hz; |

| Spare Parts Type: | petrochemical parts; | Certificate: | ISO9001; |

| After-sales Service Provided: | Video technical support,Online support; | Brand Name: | HONGYI; |

| Standard: | ASME,SONCAP,BV,ISO,CCC,CE; | Port: | wuhan/shanghai; |

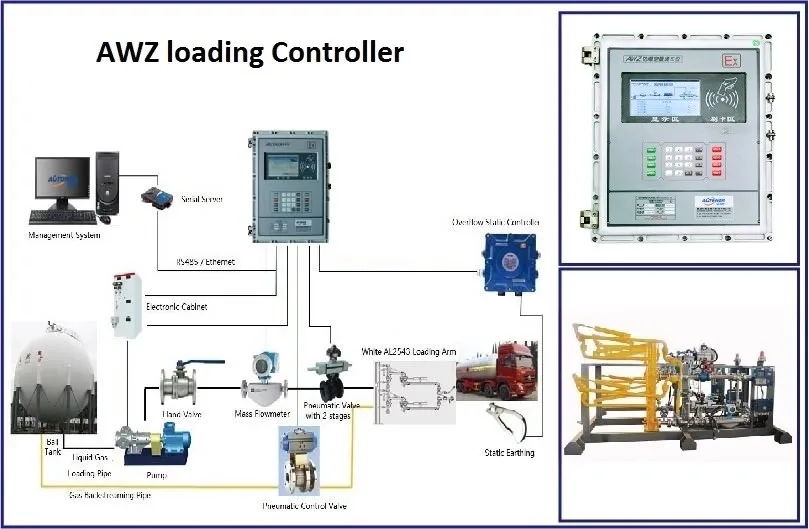

Product Application

The batch controller is a wall-mounted or cabinet-type structure with an industrial-grade intelligent controller PLC. The buttons on the controller cabinet panel adopt moisture-proof and corrosionproof stainless steel intrinsically safe keys, and the display terminal adopts an industrial-grade integrated LCD screen. Relative to the micro-controller integrated circuit has the advantages of high reliability, flexible configuration, convenient expansion, and easy maintenance

The technical parameters of the loading controller are as follow

Technical Parameters | ||

Control the number of loading arm | 1~4 loading postion | |

Power supply | 110~240VAC,2A,50Hz | |

LCD | High brightness STN liquid crystal display module. | |

IC card function | With lC card operation function | |

keyboard input | 24 keys, English menu operation or other language | |

Equipment self-test | Automatically detect device operating status and remotely monitor | |

Flow signal | Can be connected to 4 groups of 0~10KHz pulse input or two 4~20mA analog signals | |

Valve position signal | Up to 12 switch contact valves can be connected to his signal | |

Relay output | AC220V, SA, can control 10 valves or pumps (expandable more) | |

PID adjustment output | AO regulated output for adjustment of at least one PID loop | |

System accuracy | Depending on the accuracy of flow meter | |

Operation mode | Continuous operation 24 hours a day, can be operated locally or remotely | |

Working temperature | -40℃~70℃ | |

Storage temperature | -30℃~80℃ | |

Relative humidity | 0-95% | |

Setting range | 0~9999999Kg | |

Communication interface | RS232,RS485 or RJ45 | |

Communication protocol | Modbus RTU (serial port}, TCP/IP (Ethernet) | |

Communication rate | 10Mbps(Ethernet), 600 ~ 115200 bps(serial port) | |

Mean time between failures | MTBF > 100,000 hours(11 years) | |

Explosion-proof sign | ExdllBT6(IP65), ATEX Certificate | |

Installation | Wall-mounted \cabinet type | |

Dimension | 300 (length) x 400 (height) x 150 (deep) | |

Material | Aluminum, Stainless steel | |

Loading controller function

Loading controller function | ||

Quantitative loading control | IC card management function | |

Parameter setting function | Flow stability control function | |

Overflow protection | Grounding protection | |

Power-down protection | Data collection function | |

Valve continuous control function | Remote/in-place loading mode conversion function | |

Remote and local real-time monitoring | On-site instrument power supply function | |

Communication networking function | Device self-test function | |

Operation permission setting | IC card reading function | |

Temperature pressure compensation | ||

Features and functions:

1. One AWZ Loading Controller can control 1~4 loading position at same time.

2. AWZ Loading controller can control ratio of medium loading & offloading.

3. Adjust volume based on differences of density and volume which caused by temperature. There are hand-actuated and automatic ways.

4. Static grounding protection, AWZ Loading Controller can assure safety by stopping system operation once static wire don't grounded.

5. Oil Spilling protection, AWZ Loading Controller can automatically turn valve and pump off once spilled oil been detected.

6. Emergency Stopping, by pressing emergency button, system can stop working once any emergency or dangerous happen.

7. AWZ Loading controller is with remote control and site control modes, can be switched easily.

8. Power off protection, whenever working records and parameters failed to save due to power off, system can keep working based on the last records when power recovered.

9. Self detect function, AWZ Loading instrument can detect self-failure and make warning.

10. Access Authorization, AWZ Loading controller is designed to available for setting up access rights and password, which can assure security for both data and system.

11. Compatible communication protocol, AWZ Loading control device system is workable for both MODBUS and Ethernet communication.

12. On the condition of complete explosion-proof, AWZ Loading controller can read IC card and writ data, which simplify process but reinforce management.

HUBEI HONGYI ELECTRONIC&TECHNOLOGY CO.,LTD,in 2009,which covers an area of more than 3500 m2,has 4standard plants of over 6000 m2 in area,in which ,the building area of the office building ,R&D center,etc.is about 4500 m2,has more than 100 sets of nc press,nc bending machine,prectreatment system and spraying equipment that are the most advanced in china,a complete set of advanced online flow calibration system as well as a number of instrument and electronics testing equipment.We also lay emphasis on cooperation with the domestic and foreign excellent industrial control manufactures,and have established cooperation relationship with the design institutes of the Ministry of Chemical industry as well as the electronic control institutes of a number of universities.Through these cooperators,by combining our core products,we provide the users with the best system solutions.

-

Marine Scrubber Vane Demister Droplet Separator Demister

-

1000mm stainless steel elliptical hemispherical conical quasi-spherical head pressure vessel cans

-

China new design sealed top loading arm and fmc loading arm supplier

-

Floor-mounted loading control electronic cabinet with railcar top loading arms for tank farms

-

Manufacturers supply the liquid distributor through the stainless steel liquid distributor

-

Ammonia distillation unit sieve plate stainless steel perforated sieve plate

-

Protect Mail Material Inflatable Airbag Bubble Column Packaging For Cosmetics

-

2022 High-efficiency column internals trough liquid distributor

-

Rail tank car, road tank car upper and lower loading arm

-

York Mesh 431, 421, 326 Supply, Wire Mesh 2205 Mist Eliminator Factory Supplier

Other Products

-

$400.00 / set

$400.00 / set