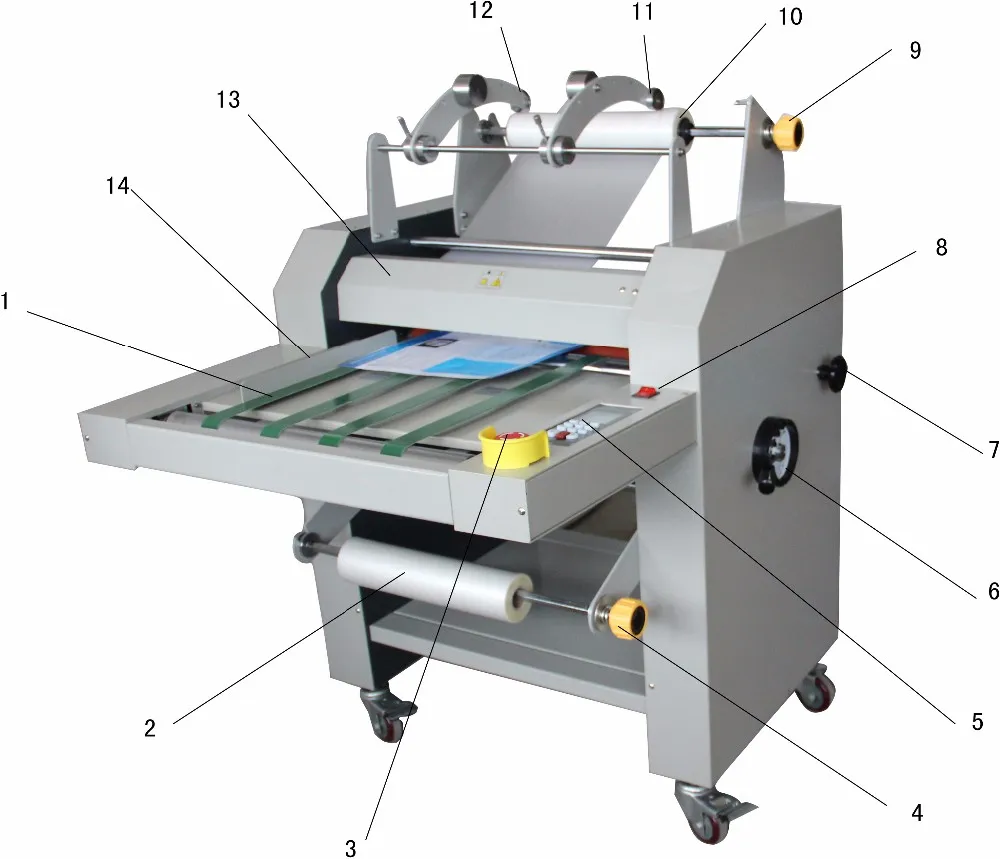

SG-490 Double sides hot and cold roll to roll laminating machine

-

Supplier: Hangzhou Fuyang Sigo Office Supplies Co., Ltd -

Region: Zhejiang, China -

Contact: Mr Andy Lee -

Price: $1050.00 /unit -

Min. Order: 1 unit

| Laminating temperature: | 60~150°C; | Driven Type: | Electric; |

| Cold&Hot Laminting: | Yes; | Brand Name: | SIGO; |

| Feeding paper: | Automatic with belt; | Selling Units: | Single item; |

| Voltage: | 110V/220V; | Type: | Laminating Machine; |

| Laminate Thickness: | 60-800gsm; | Package Preview: | https://sc01.alicdn.com/kf/HTB1anDJPsfpK1RjSZFOq6y6nFXaE.jpg_640x640.jpg; |

| Single package size: | 102X89X111 cm; | Dimension(L*W*H): | 102*89*111cm; |

| Automatic Grade: | Semi-Automatic; | Laminating speed: | 1-9m/min; |

| Max. Laminating width: | 490mm; | Single&Double Sides Laminating: | Yes; |

| Weight: | 130kg; | Condition: | New; |

| Product name: | SG-490 Double sides hot and cold roll to roll laminating machine; | Package Type: | SG-490 Double sides hot and cold roll to roll laminating machine 1pcs/ Wooden carton Carton Dimensions: 160*110*135cm G.W: 130KG N.W: 100KG; |

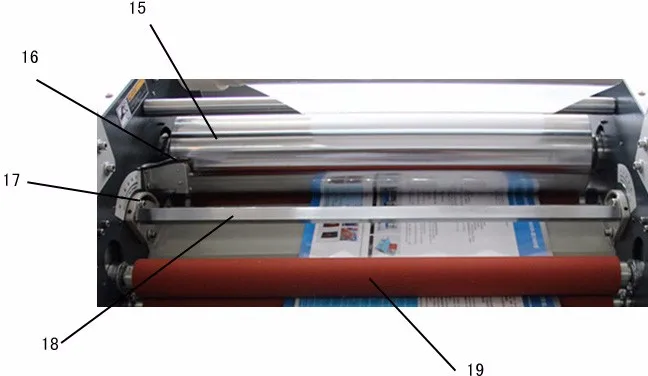

| Packaging Material: | Paper; | Heating Roller: | Big Steel Roller and Silicon Roller; |

| After-sales Service Provided: | Free spare parts,Online support,Video technical support; | Single gross weight: | 130 KG; |

| Application: | Apparel,Beverage,Commodity,Medical,Textiles; | Warranty: | 1 Year; |

| Model Number: | SG-490; | Packaging Type: | Bags,Cartons,Film,Foil,Pouch,Stand-up Pouch; |

| Delivery Detail: | 0 days after payment; | Certification: | CE ISO9001; |

| Place of Origin: | Zhejiang China (Mainland); |

SG-490 Double sides hot and cold roll to roll laminating machine

This machine covers a small area, is operated conveniently, run fast. It's equipped with automatic temperature-control and speed-regulation, automatic feeding. Several rolls or redundant rolls can be slit at one time, so this machine is regarded as a slitter.

The machine adopts pre-coated film as the material. It is widely used for lamination on the surface of window packing paper boxes, various books, maps, pictures, certificates, holographic cellphone etc. After the above products are laminated, they have the features of water-resistance, clear graphic arts and strong three-dimensional sense.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Paper cutter

100% Response Rate

Perfect binding machine

100% Response Rate

Laminating machine

100% Response Rate

Creasing machine

100% Response Rate

UV coating machine

100% Response Rate

Paper folding machine

100% Response Rate

Card cutter

100% Response Rate

Laminator

100% Response Rate

Foil stamping machine

100% Response Rate

1.Are you a factory or trading company ?

Yes, we are factory. Our factory located in Fuyang, Hangzhou.

1hour from "Hanghou Internatil Airport "to our factory. All our clients, from home or abroad, are warmly welcome to visit us!

2.How does your factory do regarding quality control?

Quality is priority. Our factory always attach great importance to quality controlling from the verybeginning to the very end. Our factory has gained CQC, ISO, SGS,FSC authentication

3.Can you give us discount if we make big order?

As a factory, we will provide offer with MOQ. If the quantity less than MOQ, we will add inland freight. If the quantity more than MOQ, we can negotiable the price.

4.How can i get some samples ?

We are honored to offer you sample to test it, around 4-5days arrived your hand after receive payment.

5.How to pay money?

We accept T/T, WESTERNUNION, WIRE TRANSFER, PAYPAL, 30% in advance,70% before shipment.

6.Can I make a OEM order?!

We can supply different sizes.our products can be customized with LOGO, PACKAGE, COLOR, etc.

Hangzhou Fuyang Sigao Office Supplies CO., LTD was founded in 2016. Our company is a synthetical enterprise occupying more than ten thousand square meters of factory building. We own import and export right.

The major products of our corporation are paper cutter, perfect binding machine, glue binding machine, wire binding machine, card cutter, laminating machine, laminaor, card cutter, creasing machine and various of binding materl (Binding plstic comb, double loops wire, spiral coil, paper cover, PVC cover, slide binder,etc). In addition, we also deal with office consumption, such as cover paper of binding,clamp bars, plastic and rubber rings, and iron rings, file bag, ruler.etc. Our products have won high reputation among customer at home and abroad for the reliable performance and novel design.

Welcome to visit our company and cooperate with us.

Thanks for your attention on SIGO. If you have any question regarding to Guillotine system---Laminator system---Binding system--Office & Printing system, Pls contact to me.

Email: sigo(@)chinaisgo.com

-

EC-650 Economical and practical electric semi-automatic cold laminating machine

-

High quality RFID chip card making machine

-

Fayon 1600DA 160cm Automatic High Speed Cold Laminator Roll Laminating Machine Cold Laminator

-

Hangzhou Befitter HT-650 650mm 25" Automatic Hot Foil Transfer Laminator

-

Cheap price large format fayon smart workbench 1325 flat laminator workbench flat laminating machine flat laminating machine

-

SWFM520C 485mm fast hydraulic manual paper feeding automatic cutting and laminating machine 0-25m/min

-

L0 Wide Format Smart FY916 Manual Cold Flat Laminator

-

Hot selling double-sided adjustable speed manual a2 a3 hot and cold laminating machine laminating machine price

-

Automatic roll laminator/Automatic roll laminating machine

-

L388 automatic roll to roll roller laminating machine with metal roller paper hot roll laminating machine for printing shop

Other Products

-

$850.00 - $900.00 / piece

$850.00 - $900.00 / piece