hdpe plastic Geomembrane Welding Machine gun ( Product List )

-

Supplier: The Best Project Material Co., Ltd. -

Region: Shandong, China -

Contact: Ms Linda Zhang -

Price: $800.00 / >=10 sets -

Min. Order: 10 sets

| Warranty of core components: | 1 Year; | Certification: | CE ISO; |

| Welding width: | 15mm*2; | Place of Origin: | Shandong China; |

| Payment Terms: | L/C,T/T,Western Union,Western Union and paypal only for sample; | After Warranty Service: | Video technical support,Spare parts; |

| Marketing Type: | New Product 2020; | Color: | Green or as per your requirements; |

| Welding speed: | 0.5---5m/min adjustable; | Brand Name: | BPM; |

| Interior cavity: | 15mm; | Applicable Industries: | Machinery Repair Shops; |

| Rated Capacity: | 100KVA; | Gross weight: | 15kg; |

| Power (kW): | 1600w; | Machinery Test Report: | Provided; |

| Usage: | spot welding,spot welding; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Condition: | New; | Voltage: | 220v,110v/220v or customized; |

| Packaging Detail: | Packed in carton box or aluminum box. Aluminum box is heavier, much safety and expensive than carton box. Or as per your requirements.; | Weight (KG): | 5; |

| Net weight: | 13kg; | Rated Duty Cycle: | 50%; |

| Port: | Qingdao ,Tianjin , Shanghai; | Supply Ability: | 1000 Set/Sets per Week Welcome your sample order; |

| Key Selling Points: | Automatic; | Thickness of material to be welded: | 0.2mm--1.5mm; |

| Dimensions: | L50cm x W37cm x H40cm; | Heating temperature: | 0---450℃ adjustbale; |

| Video outgoing-inspection: | Not Available; | Max. Welding Thickness: | 3mm; |

| Warranty: | 6 month; | Local Service Location: | None; |

| Overlap width: | 12cm; | Showroom Location: | None; |

| Core Components: | Engine; |

**Introduction

Geomembrane welder is a new welding machine which is developed by our company. They can weld geomembrane of various thickness and are applicable for welding of all thermalfused material such as LDPE, PVC, HDPE, EVA, PP and PVC,HDPE,EVA,PP

The control of this series adopt PID automatic thermostatic control with high control and low temperature fluctuation. Speed control of this series adopt PWM automatic voltage and regulation speed circuit. Direct current servo the motor drive with great output torque and staple performance in walking. It can maintain a constant speed on the condition of creeping, vertical creeping and road load. Also this series of welding machine are stable in performance despite of external temperature and voltage variation.

This series of welding machine is excellent in performance and easy for operating, with high welding speed and good work quality. It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on.

**Technical Parameter

**Main Components and Name

**Operating principle

Motor drives upper and lower pressure rollers to rotate through reduction gearbox and chain. Slide carriages drive the hot wedge and insert it between the two base materials, at the same time lever presses pressure rollers and engages the two fused base materials.

**Operating regulations

1).Use with grounded 3-cord mains cable and 3

hole socket with capacity not less than 10A (socket corresponds with welder plug, phase L connected to live wire, N to zero line, phase to grounded protection line), confirm that external lines have been well connected. Check that power is on off state and regulate temperature control potentiometer and speed control potentiometer to 0 position, press lever handle down to disengage pressure roller, then insert the plug.

2). Turn on the power and select certain temperature and speed, take several narrow materials for try welding. Temperature selection may be different for the same material at different ambient temperature and material thickness. To determine the best welding effect, adjust the speed to approximately 2m/min, and then fine increase it from low to high temperature (approximately 250℃-350℃).

3).A “T” shape overlap is formed between welded material and another material. Welding method is shown as fig.5, tightly butt the overlap head of hot wedge against weld mark, and beveling cut length is approximately 100mm.

**Maintenance

The complete machine should be cleaned, greased and placed in a dry place if it is not used.

For PVC welding, the adhesions on hot wedge should be cleaned off if it is not used longer than 4 hours to prevent wedge corrosion and service life being shortened.

Recommend: for welding of material that corrosive gas may be produced after hot fusing such as PVC and the like, stainless steel hot wedge (optional accessory) is preferred for extending of service life.

**Other products

**If you have other question ,feel free to contact me .

-

Automatic CNC contact pulse argon arc spot welding machine jewelry spot welding machine for gold and silver glasses repair

-

Hot selling 100A mini spot welding machine for jewelry welding gold, silver and copper wire portable small welding machine

-

Laser Spot Welding Machine Automatic CNC Touch Pulse Argon Welding Machine Dental Jewelry Machine Spot Welding Machine

-

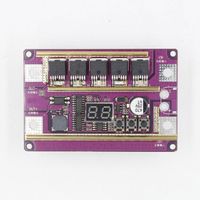

12V Spot Welder DIY Kit 99 Power Adjustable Spot Welding Control Board for Welding 18650 Battery Nickel Sheet with Shell

-

Handheld mini spot welder 6 gears adjustable DIY spot welder with nickel sheet for 18650 battery plate spot welding

-

High Power Laser Spot Welder Dental Orthodontic Welder Automatic CNC Pulse Welder For Welding Jewelry

-

Relife RL-936W battery welding machine adjustable 6-speed mobile phone battery spot welding micro-welding repair tool

-

12V Fully Automatic 18650 Lithium Battery Spot Welding Machine Full Accessory Set with Spot Welding Pens

-

Spot Laser Welding Machine Automatic CNC Touch Pulse TIG Welding Machine for Welding Jewelry

-

DIY Portable 12V Battery Storage Spot Welder PCB Circuit Board Welding Equipment Spot Welding Pen for 18650/26650