10kg Trial Small Waste Tire Pyrolysis Plant Pyrolysis Machine Transform Tires Into Fuel Mini Plastic Recycling Machine

-

Supplier: Xinxiang Huayin Renewable Energy Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Huayin Group -

Price: $19000.00 /set -

Min. Order: 1 set

Product details

| Condition: | New; | Key Selling Points: | Safe, no oil gas leakage, pollution free, energy-saving; |

| Applicable Industries: | Manufacturing Plant,Farms,Construction works ,Energy & Mining,Energy Mining; | Certification: | ce,ISO,GS,Sgs,UL; |

| Place of Origin: | China; | Packaging Detail: | one 20''GP or LCL; |

| Payment Terms: | L/C,T/T; | Function: | showcasing/testing tire plastic to oil recycling; |

| Power consumption: | about 0.6kwh per batch; | Video outgoing-inspection: | Provided; |

| Warranty: | 1 Year; | After-sales Service Provided: | Installation video, manuals and field installation,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Marketing Type: | Hot Product 2019; | Warranty of core components: | 1 Year; |

| Package Preview: | ; | Machinery Test Report: | Provided; |

| Local Service Location: | South Africa; | Raw material: | Waste Tyre Waste Plastic; |

| Brand Name: | HUAYIN; | Capacity: | 10kg per batch (taking 4-6hours to finish); |

| Power (kw): | 0.12kw; | Equipment Capacity: | 10kg per batch (taking 4-6 hours to finish); |

| Oil yield: | 40-50% fuel oil, 25%-30% carbon black, 15%-20% steel wire; | Core Components: | Gearbox,Motor,Pressure vessel,Gear; |

| Weight (KG): | 500; | Type: | Tyre Recycling Pyrolysis Plant; |

| Material: | Stainless steel; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Showroom Location: | Egypt,Canada,Germany,Ukraine; | Voltage: | 380v/50HZ(as Customers' Request ); |

Product Overview

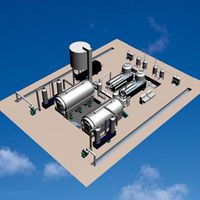

Mini 10kg Tire Plastic Pyrolysis Plant for Pilot Testing Use

This mini plant is very popular for showcasing or testing use. It can processing tire/plastic to heavy fuel oil, steel wire (for tire), carbon black and syngas.Some clients use this to test whether their materials can produce oil or not, the oil quality, oil yield, etc.

Some clients show its environmental running process to government to get license or to potential clients.

Already installed in Canada, Israel, Singapore, Malaysia, Germany, Egypt, Russia, France, etc.

FEATURES AT A GLANCE

Low cost to try the raw materials.

Quick operation. One batch takes 4-6 hours. You can test 4-6 batches in one day.

Easy to operate. Very user-friendly. One worker is ok.

Easy to move. You may take it to different locations for testing and showcasing.

It’s totally the same design as 10T pyrolysis plant. Stainless steel.

It only needs 4-6hours to do one batch.

It can get 4-5kg tire heavy fuel oil (plus 2-3kg carbon black, 1.5-2kg steel wire and 5%-10% tail gas) or 2-7.5 plastic heavy fuel oil.

Applicable Raw Material | Approximate Oil Ratio |

Submarine cable | 75% |

Rubber cable | 35% |

Sole | 30% |

Big tires (truck tires and OTR tires) | 45%-50% |

Small tires (car tires and motorcycle tires) | 35%-40% |

PP (microwave oven food box/yogurt bottles etc) | 50%-75% |

PE(plastic film /plastic wrap) | 50%-75% |

PS (smack-box/blister box) | 50%-75% |

ABS (engineering plastics) | 40% |

Leftovers of paper | Wet 15-20%, dry 60% |

House garbage | 35-50% |

Plastic cable | 80% |

Plastic bag | 50% |

PVC (raincoat/building materials) | Not suitable because chlorine in PVC will corrode the reactor and shorten the service life. But small amount of PVC is Ok. If a big amount, we suggest you to separate PVC out in advance and process it in other ways. |

PET (water bottles/sodas beverage) | Not suitable because it contains very little oil and not worthwhile for pyrolysis. But small amount of PET is Ok. If a big amount, we suggest you to separate PET out in advance and process it in other ways. |

Good feedback from customers

FAQ

1. Who has run the waste tire/plastic to oil recycling pyrolysis machines?

A: The waste tire/plastic to fuel recycling pyrolysis machines have been installed in 76 countries all over the world.

2. What can I get from the machines?

A: From 10T pyrolysis machine, you can get 4-5T tire oil or 2T-7.5T plastic oil, 2.5-3T carbon black, 1.5-2T steel wire, 5%-10%

syngas.

3. How much profit do I get from the pyrolysis machine? What's in it for me?

A: This machine can get you hundreds to over 1,000USD profit gross profit per day.

The accurate profit varies with your local raw material cost, amount and your output selling price. If you provide these prices,

we can give you a specific profit analysis report.

By the way, the more tyre/plastic you process per day, the lower the average management cost and the more profit you get.

4. What matter most to this waste tire/plastic to oil recycling pyrolysis business?

A: Safety. It's the most important thing in this high-profit oil gas business. Environment friendly Energy-saving

Installation&worker training Technical support&update Service

A: The waste tire/plastic to fuel recycling pyrolysis machines have been installed in 76 countries all over the world.

2. What can I get from the machines?

A: From 10T pyrolysis machine, you can get 4-5T tire oil or 2T-7.5T plastic oil, 2.5-3T carbon black, 1.5-2T steel wire, 5%-10%

syngas.

3. How much profit do I get from the pyrolysis machine? What's in it for me?

A: This machine can get you hundreds to over 1,000USD profit gross profit per day.

The accurate profit varies with your local raw material cost, amount and your output selling price. If you provide these prices,

we can give you a specific profit analysis report.

By the way, the more tyre/plastic you process per day, the lower the average management cost and the more profit you get.

4. What matter most to this waste tire/plastic to oil recycling pyrolysis business?

A: Safety. It's the most important thing in this high-profit oil gas business. Environment friendly Energy-saving

Installation&worker training Technical support&update Service

Why Choose Us

Why buy from Huayin?

A: Huayin can offer all these above things: Safety, environmental compliance, Energy-saving, good installation&worker

training as well as Technical support&update Service.

Because Huayin has:

1) Christian background. So Huayin honor our promises. You can trust and reply on us.

2) 10 years' plant using experience, so Huayin stands in your shoes;

3) 17 years' manufacturing factory experience, paying attention to improving plant details;

4) Huayin's own technical team, giving you technical support;

5) 76 countries' installation experience by Huayin's own installation team, ensuring good plant installation and good worker

training.

6) Specially built After-sales Service Department, serving you 24/7.

7) Good domestic market, a proof of Huayin's plant performance and reputation.

A: Huayin can offer all these above things: Safety, environmental compliance, Energy-saving, good installation&worker

training as well as Technical support&update Service.

Because Huayin has:

1) Christian background. So Huayin honor our promises. You can trust and reply on us.

2) 10 years' plant using experience, so Huayin stands in your shoes;

3) 17 years' manufacturing factory experience, paying attention to improving plant details;

4) Huayin's own technical team, giving you technical support;

5) 76 countries' installation experience by Huayin's own installation team, ensuring good plant installation and good worker

training.

6) Specially built After-sales Service Department, serving you 24/7.

7) Good domestic market, a proof of Huayin's plant performance and reputation.

VIEW MORE

You may like

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

Other Products

-

$15000.00 / set

$15000.00 / set -

$35000.00 / set

$35000.00 / set -

$35000.00 / set

$35000.00 / set -

$41000.00 / set

$41000.00 / set -

$45000.00 / set

$45000.00 / set

Related Search

small waste tire recycling machine

fully automatic waste tire pyrolysis plant suppliers

oil yield waste tire machine for pyrolysis

automat wast tyre pyrolysi plant to diesel suppliers

waste tires tyre pyrolysis machine

waste tire oil pyrolysis

fully continuous waste tyre pyrolysis plant suppliers

waste tires pyrolysis fuel oil

water cooling waste tyre/rubber pyrolysis machine/

pyrolysis waste plastic recycling machinery