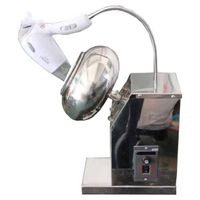

copper pharmaceutical tablet candy sugar coating machine

-

Supplier: Taizhou Jincheng Pharmaceutical Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Jason Xu -

Price: $2115.00 /set -

Min. Order: 1 set

| After Warranty Service: | Online support; | Raw material: | Nuts Beans Sugar Chocolate Pill or Tablet; |

| Supply Ability: | 50 Set/Sets per Month sugar coating machine; | Key Selling Points: | Automatic; |

| Marketing Type: | Ordinary Product; | Package Preview: | ; |

| Type: | Sugar coating Pan Machine; | Packaging Detail: | sugar coating machine packed in plywood wooden box, meet export standard; |

| Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,Pharmaceutical Industry; | Coating Temperature (℃): | 20 - 70 ℃; |

| Power (kW): | 1; | Warranty of core components: | 1 Year; |

| Machinery Test Report: | Not Available; | Core Components: | Motor; |

| Pan material: | Copper; | Product Name: | pharmaceutical tablet chocolate sugar coating machine; |

| Rotating speed: | 8-35rpm; | Capacity: | 10-70KG; |

| Payment Terms: | T/T,Alibaba trade assurance; | Brand Name: | Jincheng; |

| Usage: | Pharmaceutical Chemical or Food Industries; | Showroom Location: | None; |

| Packaging Details: | plywood wooden box; | Function: | coating film; |

| Weight (KG): | 275; | Condition: | New; |

| Warranty: | 1 Year; | Pan size: | diameter:600,800,1000mm; |

| Place of Origin: | Jiangsu China; | Dimension(L*W*H): | 1310*1420*1030(mm); |

| Certification: | CE; | Port: | SHANGHAI; |

| Coating Type: | Heating & Coating; | Local Service Location: | None; |

| Coating Drum Diameter (mm): | 600; | Video outgoing-inspection: | Provided; |

| Pan shape: | Round; | Voltage: | 110V; |

| After-sales Service Provided: | Video technical support,Online support; |

copper pharmaceutical tablet candy sugar coating machine

BYQ series Sugar coating machine is mainly used for coating film for tablet, pill,granule,crystal, capsule and seed in different industries. The machine can also coat film, make powder into granules or pills, polish and mix without replacing any equipment components.

When the machine is working, the coating pot, reducer and motor are on the same center line of axis, the electric motor drives the coating pot to rotate clockwise through the reducer, and the materials in the pot roll under the centrifugal force and friction. The pot is equipped with an agitator, so that the materials can be evenly stirred.If the materials in the pot are sprayed with moistening agent, adhesive or coating medium, the procedures of coating, granulating, polishing and blending can be completed. This machine uses the method of single arm to support the pot body. the pot body is driven by the motor and reducer so that the single arm drives the pot body to make directional rotation movement.When the opening of the pot is turned to the top, the charging process can be carried out. When the opening of the pot is turned to the bottom, the materials in the pot can be poured out quickly. If the user adds the charging device, the loading and unloading automation can be realized, which greatly reduces the heavy labor of manual loading and unloading. A gas heater is installed under the bottom of the pot, which improves the heating speed of the pot and reduces the production cost.

| Model | BYQ-600 | BYQ-800 | BYQ-1000 |

| Diameter(mm) | 600 | 800 | 1000 |

| Rotating speed(rpm) | 8-35 | 8-32 | 8-32 |

| Motor power(KW) | 0.75 | 1.1 | 1.5 |

| Unloading power(KW) | 0.25 | 0.55 | 0.75 |

| Heating Method |

Gas stove heating (natural gas, liquefied gas) |

||

| Capacity(KG) | 10-25 | 30-50 | 50-70 |

| Dimension(mm) |

1310*1420*1030 |

1550*980*1550 |

1650*1100*1650 |

| Weight(KG) | 275 | 335 | 365 |

-

BYC-600 sugar coating machine is used for sugar coating of tablets and pills in the food industry

-

Nut/Chocolate/Almond Peanut Candy Coating Pan Machine Nut Icing Machine

-

Hot Sale Stainless Steel Small Pill Candy Sugar Diaphragm Coating Machine

-

BYC 800 sugar coating machine, tablet and pill coating machine, sugar coating machine

-

Commercial Fondant Sugar Coating Machine Almond Nut Peanut Solution Coating Machine

-

Hot Sale All Stainless Steel Tablet Film Coating Equipment Sugar Coating Machine

-

Laboratory Tablet Coating Machine Pharmaceutical Equipment

-

Food Small Automatic Nut Candy Candy Chocolate Peanut Almond Candy Tablets Nano Film Coating Pot Machine Coating Machine

-

Polishing machine Peanut tablet coating machine

-

Small candy nut icing pan machine

Other Products

-

$300.00 - $350.00 / set

$300.00 - $350.00 / set -

$400.00 / set

$400.00 / set -

$350.00 / set

$350.00 / set -

$1050.00 / set

$1050.00 / set -

$1300.00 / set

$1300.00 / set -

$1550.00 / set

$1550.00 / set