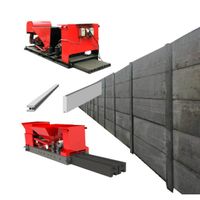

Concrete Panel Moulds Hollow Core Panel Machine Hollow Core Slab Machine Hollow Core Wall Panel Machine

-

Supplier: Jinan Libo Jinggong Machinery Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Mr LIBO MACHINERY -

Price: $12000.00 /set -

Min. Order: 1 set

| power: | 4KW; | Supply Ability: | 100 Set/Sets per Month; |

| Showroom Location: | None; | Key Selling Points: | Energy saving; |

| After the warranty: | Charge for parts and non work hours; | voltage: | 380V; |

| Warranty of core components: | 1 Year; | Automatic Grade: | Automatic; |

| Warranty period: | 1 year; | Port: | qingdao,China; |

| Machinery Test Report: | Provided; | Applicable Industries: | Manufacturing Plant,Construction works ; |

| Brand Name: | Libo; | Characteristics: | One machine is multi-purpose; |

| Core Components: | Large plate of main machine mould; | Local Service Location: | Viet Nam,Philippines,Peru,Indonesia,Pakistan,Thailand,Australia,Argentina,Bangladesh; |

| weight: | 6T; | Condition: | New; |

| project: | Lightweight wall panel machine; | Warranty: | 1 Year; |

| Voltage: | 380V; | Place of Origin: | Liaoning China; |

| Marketing Type: | Ordinary Product; | After Warranty Service: | Video technical support,Online support,Field maintenance and repair service; |

| size: | 3000mmx3600mmx1100mm; | After-sales Service Provided: | Online support,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Weight: | 6; | Power: | 4KW; |

| Production Capacity: | 20 pieces; | Video outgoing-inspection: | Provided; |

| productivity: | 20 pieces; | Dimension(L*W*H): | 3000mmx3600mmx1100mm; |

| Payment Terms: | T/T; |

1. Is your company a manufacturing company or a trading company?

We are a direct factory, not an agent or trading company, quality and after-sales service are guaranteed.

2. How can I trust the quality of the machine?

Our products have passed ISO9001 certification, have 20 years of experience in mechanical manufacturing, and constantly update technical concepts and technical applications. As a result, our machines have been exported to 50 countries and regions, and have always enjoyed a good reputation for customers abroad. We will conduct a comprehensive test on the products before sintering to ensure that each device can work normally when delivered.

3. When will you deliver the goods?

Usually 30 months after receiving the deposit and booking confirmation.

4. How about the debugging of the machine and the training of the workers?

Yes, after the wall panel production line is installed,

Our engineers will carry out testing and debugging, and prepare the most suitable material ratio to make wall panels, and train workers how to operate and maintain the machine.

5. Is the production process of wallboard complicated?

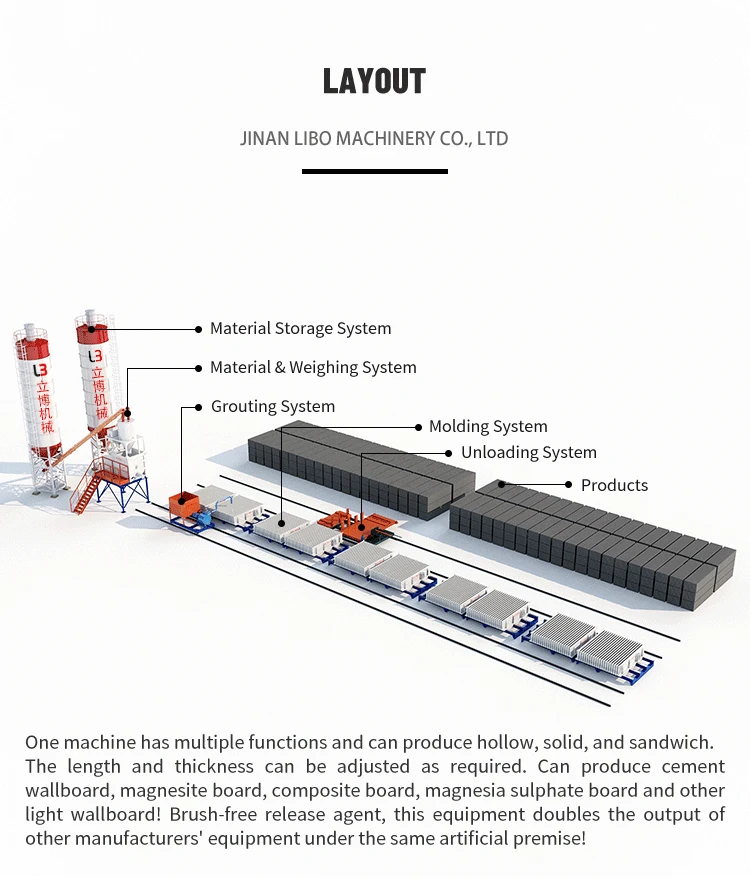

Very simple, not complicated. Mixing of raw materials → injecting into the molding mold → taking out after solidification → product storage.

6. What kind of wall panels can be produced?

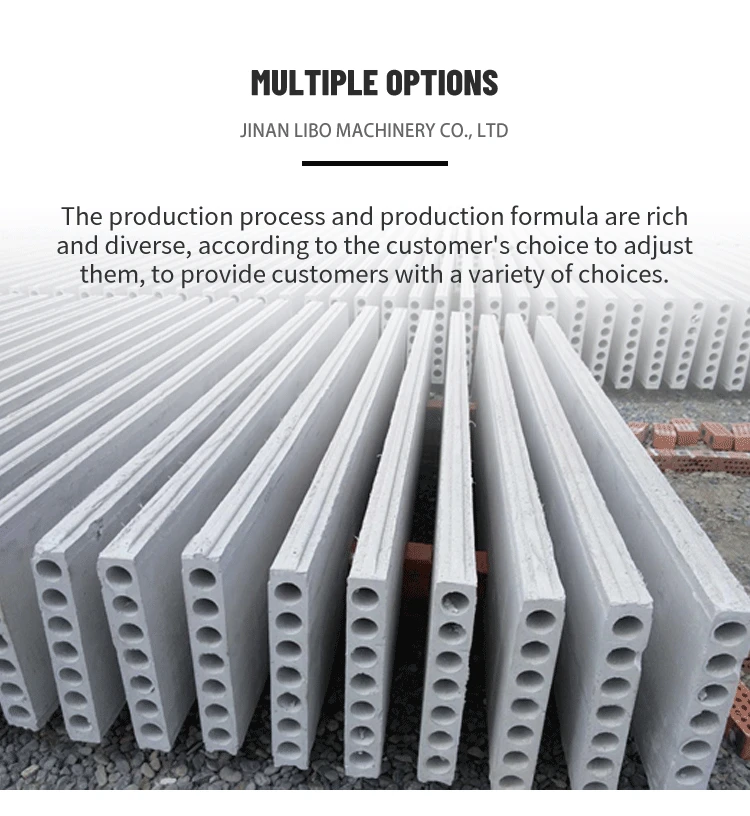

We can produce many types of wall panels, hollow wall panels, solid wall panels, composite sandwich wall panels, etc. Multi-purpose machine with adjustable thickness and length.

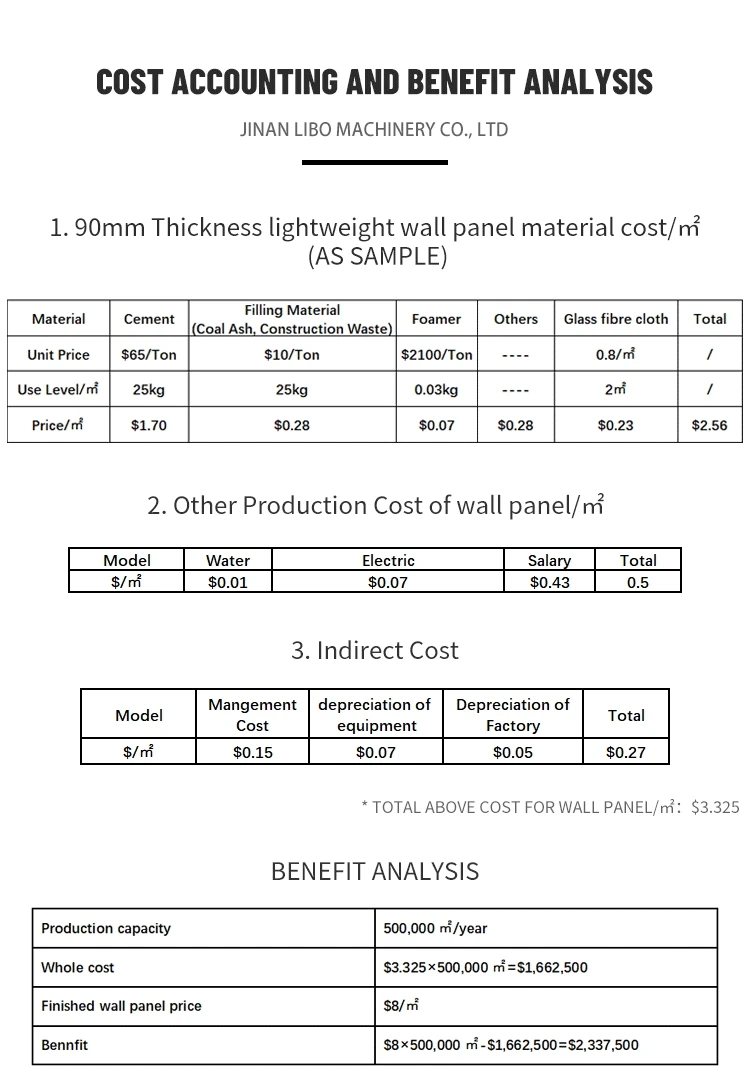

7. Is the production of wallboard a big investment?

The amount of investment is related to the scale of production, the output you need, and the degree of automation of supporting facilities and equipment. With an annual production line of 100,000 square meters, equipment investment is 500,000 to 1 million, and the profit can reach about 3 million! The investment can be large or small, and the size of the production line can also be freely combined according to needs, and the degree of automation of the equipment can also be selected.

8. How much space is needed to produce wall panels?

The size of the site depends on the size of the equipment purchased, usually no less than 5 acres (about 4000 square meters), if conditions permit, the best 10 acres (about 8000 square meters).

-

Concrete wall fence panels/precast concrete fence moulds/hollow cement slab wall precast parts for sale

-

Prefabricated hollow panel/sandwich panel production line/prefabricated concrete mold for prefabricated board room

-

Double Layer Roll Forming Machine Roll Forming Machine Metal Roof Corrugated Steel Sheet Wall Panel Tile Making Machine

-

Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

-

precast concrete formwork/precast concrete stairs

-

Concrete Precast House Precast House Precast Concrete Fence Mold Plastic EPS Hollow Panel Sandwich Panel Machine

-

Prestressed concrete T-beam machine

-

Concrete Wall Panel Making Machine Light Weight Precast Wall Panel Machine for Concrete Panels

-

Sheet Manufacturing Machinery Embossing Machine Products 2020 Automatic Flooring Building Materials Embossing Metal New

-

precast compound concrete hollow core wall panel making machine

Other Products

-

$12000.00 - $14000.00 / set

$12000.00 - $14000.00 / set