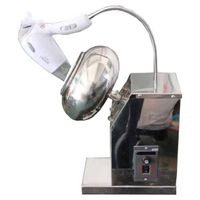

BGB Series High-Efficient Tablet Film Coater Coating Machine

-

Supplier: Shanghai Pharmaceutical Machinery Co., Ltd. -

Region: Shanghai, China -

Contact: Mr Ted Bian -

Price: $40000.00 /set -

Min. Order: 1 set

| Showroom Location: | None; | Supply Ability: | 1 Set/Sets per Year; |

| Place of Origin: | Shanghai China; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Warranty of core components: | 1 Year; | Key Selling Points: | Long Service Life; |

| Applicable Industries: | medical; | Max. Load Capacity (kg): | 1000; |

| Certification: | ISO9001; | Packaging Detail: | Export standard packaging; |

| Payment Terms: | L/C,T/T,USD, EUR; | Local Service Location: | None; |

| Machinery Test Report: | Provided; | Coating Drum Diameter (mm): | 100; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Voltage: | 220V/380V; |

| Video outgoing-inspection: | Provided; | Warranty: | 1 Year; |

| Core Components: | Engine; | Usage: | Pharmaceutical; |

| Condition: | New; | Marketing Type: | Hot Product 2019; |

| Coating Temperature (℃): | 10 - 20 ℃; | Coating Type: | Heating & Coating; |

| Weight (KG): | 1000kg; | Port: | Shanghai; |

BGB Series High-Efficient Tablet Film Coater Coating Machine Specifications

1. High-efficiency coating machine

2. Fully enclosed.

3. Meet cGMP.

tablet coaters

BGB Series High-Efficient Film Coating Machine

Usage:

The BGB Series high efficiency film coating machine is mainly used in pharmaceutical and food industries.Featuring macaronis and conforming to the requirement of GMP, it is a high efficiency, energy saving, safe and clean equipment for coating tablets, pills and candies with organic film, water soluble film, slow and controlled release film, sugar film and etc.

Features:

All the operations, including expansion of PLC module, setting and control of hot air temperature and adjustment of drum speed, are carried out on the touch keys of control panel of computer, and the operating panel is a fully closed light touch film interface which does not influence the cleaning of main machine, thus featuring reliable work, stable performance and conforming to the requirement of GMP.

Under the action of the agitator of steam line guide plate type, the tablet cores are tumbling smoothly and exchanging frequently, thus eliminating the phenomenon of tablet cores to fall from a high place and to collide, solving the problems of broken pieces and chipped edge, and improving the rate of finished products. The narrow surface of the guide plate eliminates the adhesion of coating material on its surface, thus saving the coating material and improving the quality of medicine.

The peristaltic pump with constant pressure variable eliminates the need for a return pipe. The turning radius of the drum varies along with the pressure change. The output slurry and the quantity of slurry sprayed are balanced automatically, thereby stabilizing the effect of atomization, simplifying the spray system, preventing the spray gun from plugging-up, and saving the coating material, moreover the cleaning is simple, and there is no dead corner.

The spray gun specially designed for the film coating machine features even atomization and large coverage of spraying. The universal adjustable spray head makes the cleaning mechanism of spray gun unaffected by charge quantity, so that film coating can proceed continuously, thus reducing the film coating time and saving film coating material.

Accessory and equipment for the coater:

AGITATING TANK, PERISTALTIC PUMP, SPRAY GUN AND DISTRIBUTOR, EXHAUST MACHINE.

| Model | 10 | 40 | 80 | 150 |

| Working capacity(Max/Min)L | 10/3 | 40/20 | 80/40 | 150/70 |

| Rotary Speed of Roller (rpm) | 2-20 | 2-20 | 2-20 | 2-20 |

| Main motor (KW) | 0.75 | 1.1 | 1.1 | 2.2 |

| Filter motor (KW) | 0.75 | 2.2 | 2.2 | 2.2 |

| Deduster Fan (KW) | 1.1 | 2.2 | 3 | 5.5 |

|

Overall dimension of main machine (L×W×H)(mm) |

1000*750*1500 | 1160*790*1730 | 1200×960×1580 | 1550×1120×1990 |

|

Dimension of Filter Cabinet (mm) |

620*720*1510 | 870*710*1800 | 1050*1050*1900 | 1200*1200*2100 |

| Dimension of Deduster Cabinet (mm) | 550*600*1530 | 830*730*1800 | 850*750*1900 | 900*800*2050 |

-

BYC-600 sugar coating machine is used for sugar coating of tablets and pills in the food industry

-

Nut/Chocolate/Almond Peanut Candy Coating Pan Machine Nut Icing Machine

-

Hot Sale Stainless Steel Small Pill Candy Sugar Diaphragm Coating Machine

-

BYC 800 sugar coating machine, tablet and pill coating machine, sugar coating machine

-

Commercial Fondant Sugar Coating Machine Almond Nut Peanut Solution Coating Machine

-

Hot Sale All Stainless Steel Tablet Film Coating Equipment Sugar Coating Machine

-

Laboratory Tablet Coating Machine Pharmaceutical Equipment

-

Food Small Automatic Nut Candy Candy Chocolate Peanut Almond Candy Tablets Nano Film Coating Pot Machine Coating Machine

-

Polishing machine Peanut tablet coating machine

-

Small candy nut icing pan machine

Other Products

-

$6600.00 / set

$6600.00 / set -

$5000.00 / set

$5000.00 / set -

$800.00 / set

$800.00 / set