Polypropylene multifilament spinning machine fdy extrusion extruder line yarn machine for sewing bags

-

Supplier: Taian Jiamei Machinery Technology Co., Ltd. -

Region: Shandong, China -

Contact: Ms Susan Sun -

Price: $95000.00 /set -

Min. Order: 1 set

| Power: | 80kw; | Applicable Industries: | Manufacturing Plant,textile plant; |

| Packaging Detail: | export safety packing Polypropylene spinning machine fdy extrusion extruder yarn making machine for sewing bags; | winder speed: | 2200m/min; |

| After Warranty Service: | Video technical support,No service,Online support; | Video outgoing-inspection: | Provided; |

| Marketing Type: | Hot Product 2019; | Warranty of core components: | 1 Year; |

| Package Preview: | ; | Brand Name: | JIAMEI; |

| Single gross weight: | 50.0 KG; | Application: | Spinning Line; |

| Production Capacity: | 2000m/min; | Showroom Location: | Egypt,Brazil,Russia,Argentina,South Korea,Malaysia; |

| Spinning Method: | Ring Spinning; | Name: | PP FDY Spinning Machine; |

| Dimension(L*W*H): | 6000x5500x7000MM; | power: | 80-90kw; |

| Selling Units: | Single item; | Scope of application: | Spinning Inductrial; |

| Material: | Polypropylene; | Single package size: | 40X30X40 cm; |

| Automatic: | yes; | Core Components: | PLC,Motor; |

| Yarn size: | 800D; | ends: | 6.8.12; |

| After-sales Service Provided: | Free spare parts,Video technical support,Online support,Field installation, commissioning and training; | Warranty: | 1 Year; |

| Condition: | New; | inverter: | delta; |

| Machinery Test Report: | Not Available; | Usage: | PP Yarn Making Machine; |

| Place of Origin: | Shandong China; | Certification: | CE; |

| voltage: | 220v/380v; | Type: | Spinning Production Line; |

| Local Service Location: | Philippines,Brazil,Indonesia,Argentina,Romania,Ukraine; | Weight: | 20TON; |

Polypropylene spinning machine fdy extrusion extruder yarn making machine for sewing bags

FDY PP MULTIFILAMENT YARN SPINNING MACHINE:

FDY by processing of extruding, melting, spinning and drawing, consists of spinning machine, winder.

II. Technical process of FDY yarn spinning machine:

Chips→ extruder→ extruding head →melt pipe with static mixer→ spinning beam with oil heating →quenching delay→ quenching chamber → oiling system → feeding roller →migration nozzle→ four pairs of hot godet→ inter lacing jets→ take-up winder →final product

Technical :

|

Unit |

Machine Model |

|||

|

|

JM241 |

JM811 |

JM161 |

|

|

No. of pos. |

Pos. |

2 |

2 |

1 |

|

titer |

dtex |

|

||

|

No.of ends/pos. |

Spinner/pos. |

6 |

4 |

8 |

|

spinneret |

mm |

160 |

160 |

160 |

|

Metering pump |

cm³/rpm |

12cc/rpm |

||

|

winding speed |

M/min |

1800-2500m/min |

||

|

Output/24Hr(900d) |

Kg |

3456 |

2304 |

2304 |

|

Bobbin size |

mm |

¢125*¢110*200 |

¢125*¢110*200 |

¢108*¢94*230 |

|

Package size(mm) |

mm |

¢400*¢125*170 |

¢400*¢125*170 |

¢360*¢108*200 |

|

Dia .of screw |

mm |

120 |

105 |

90 |

|

L/D |

|

30:1 |

||

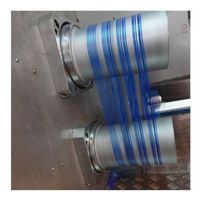

Machine Photos Show:

Polypropylene spinning machine fdy extrusion extruder yarn making machine for sewing bags

Yarn picture:

Sepcification:

pp fdy multifilament spinning machine 1.automatic pp fdy yarn machine 2.good quality yarn 3.high capacity

1. Technical Description

Multifilament spinning plant

Model: JMHT-161

This multifilament spinning plant is designed for the production of fully drawn yarn “FDY” in particular PP multifilament yarn with a titer of 500 to 2000 denier to be used for diverse textile and technical applications.

The tenacity of multifilament yarn from this line is not less than 7g/den.

1.1.Process characteristics

The process applied on this line includes the direct stretching and intermingling of the yarn in one step, which has the following advantages.

1.) Best relation between capital investment and output.

2.) Low production costs because of one-step process, reducing space, labor and energy-consumption.

3.) Inline spin-finish application

4.) Elimination of twisting due to intermingling process.

5.) The short polymer residence time ensures high flexibility and versatility for the production with high quality colored yarn.

1.2. Components description

The extruder plasticizes and homogenizes the polymer and feeds it into the electrically heated spinning head.

The precision gear pump force controlled the melt to the spinning packs with the spinnerets. In the quenching cabinet the filaments are quenched by air.

Subsequently they are bundled together, provided with spin-finish oil, drawn, intermingled and wound up to bobbins.

Polypropylene spinning machine fdy extrusion extruder yarn making machine for sewing bags

The daily output calculation is

Based on 1000denier,1 winders ,4cops of each winder,

winding speed2200m/min, efficiency 96%

1000*1*4*2200*60*24*0.96

Q= ---------------------------------------=1.35(ton/day)(For your reference)

9000*1000*1000

Confirm Some Questions Below:

1. whats the pp multifilament yarn production range ?

2. make mainly in color yarn or white yarn ?

3. whats the machine capacity for exactly yarn size ?

4. whats the yarn tenacity ?

Contacts:

-

Thermal godet/spinning machine godet

-

GA747-III Flexible Sword Loom Simple Sword Loom No Ship To China

-

Rieter 20 2002 used starter

-

Refurbished high automatic dobby jacquard loom rapier loom loom

-

Tongda FA1569 Textile Cotton Yarn Machine Production Line Ring Spinning Machine Price

-

Large Capacity New China Silk 2-in-1 Yarn Twister Machine

-

Rieter K44 tension wheel

-

Textile Production Line Blowing Carding Machine

-

JD758B Towel bar loom

-

Home Small Loom Weaving Beginner Loom Special Loom

Other Products

-

$1450.00 / set

$1450.00 / set -

$103500.00 / set

$103500.00 / set -

$96000.00 / set

$96000.00 / set -

$92000.00 / set

$92000.00 / set -

$9950.00 / set

$9950.00 / set