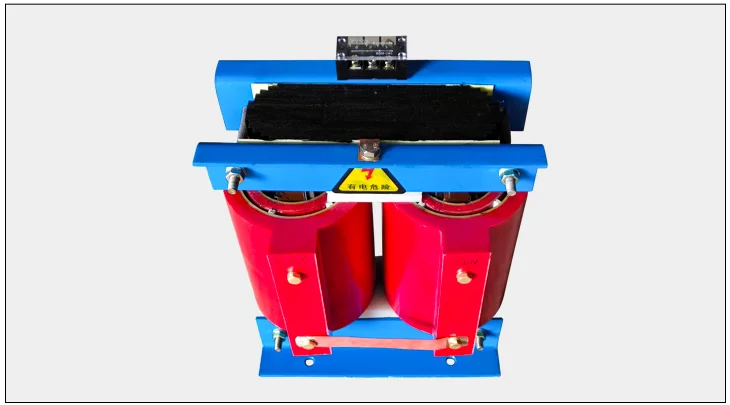

Three-phase epoxy cast high-voltage transformer power,50KVA 220V/380V 3 phase transfommer,can be customized special transformer

-

Supplier: Zhejiang Shuntong Electric Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Qiang Li -

Price: $46.00 /set -

Min. Order: 1 set

| Packaging Detail: | Standard package; | Phase: | Three; |

| No-load current: | 1.0~1.8%; | Usage: | Instrument; |

| Model Number: | Single-phase high-voltage power transformer; | Payment Terms: | L/C,T/T,Western Union,MoneyGram; |

| Place of Origin: | Zhejiang China; | Model: | 50KVA~1250KVA; |

| Product type: | IP20; | Output Voltage: | 15v; |

| Ambient temperature: | -15℃ - 40℃; | Coil Number: | AUTOTRANSFORMER; |

| Connection Group: | Dyn11 / Dy11; | Brand Name: | SNTOOM; |

| Input Voltage: | 220v/380v; | Coil Structure: | TOROIDAL; |

| Product name: | Three-phase high-voltage power transformer; | Port: | Ningbo; |

| Supply Ability: | 500 Set/Sets per Week; | Frequency: | 50/60Hz; |

| Short-circuit impedance: | 4% / 6%; |

Three-phase High-voltage Power Transformer

1.Product introduction

Three-phase high-voltage power transformers can be widely used in industry, such as start spot welding machine, automatic welding machine, butt welding machine, straightening machine, steel wire rolling machine, diffusion welding machine, seam welding, roll welding, touch welding, row welding machine etc.

2. Normal operating conditions

Three-phase high-voltage power transformer should be able to work normally under the following conditions:

a) Altitude: not more than 1000m;

b) Ambient temperature: -15 ℃ ~ + 40 ℃

c) The relative humidity of the air does not exceed 95% (at + 25 ℃);

d) In a gas or steam environment without damage to insulation;

e) Used in explosive environment without methane coal dust.

3. Product parameters

| Product name | Three-phase high-voltage power transformer |

| Capacity | 50kVA |

| Frequency | 50/60Hz |

| Input voltage | 220/380V (can be customized) |

| Output voltage | 15V(can be customized) |

| Ambient temperature | -15 ℃ ~ + 40 ℃ |

| Insulation resistance | ≥50MΩ |

| Effectiveness | 95% |

| Waveform distortion | No additional waveform distortion |

| Overload capacity | 2 times rated current, maintain 1min |

| Note: Special current and voltage can be customized according to requirements! | |

4.Product details

1) The primary coil is fired with 180° high temperature resistant insulated enamelled pure

copper wire, and the windings are neatly arranged to improve the withstand voltage level

and reduce the no-load loss.

2) The iron core made of cold-rolled silicon steel sheets is closely stacked,

neatly arranged and tightly structured, with high magnetic flux density, reducing loss and

noise, and saving energy.

3) The high-voltage transformer is cast with epoxy resin, which has the characteristics

of insulation, corrosion resistance and heat resistance, which improves the insulation

effect of the transformer.

4) Single-phase high-voltage transformer secondary is wound with high temperature

resistant copper wire, high conductivity, low resistance, low loss, improve productivity,

and can be customized according to requirements.

5.Product shows

-

Shunhong 3000w step-down power transformer 220v to 110v 230v 240v voltage converter 220 110 ring

-

2000W step-up transformer multi-purpose electrical appliance supports the use of 220 to 110 or 110V to 220V step-up converter 220v to 110v 2000

-

Power transformer EI28 1W DB-1VA 220V to 6V/9V/12V/15V/18V/24V/single/dual input voltage 220V

-

500w step up transformer 110V 220V power supply AC transformer

-

220VAC/110VAC 500VA power transformer

-

Oil Price Transformer Immersed Transformer 3 Phase 10kv 20kv 125kva Oil Powered Power High Voltage Transformation

-

High quality transformer 900w 1000W for microwave oven

-

Dedicated TV Flyback Transformer

-

Household fully automatic AC 110V to 220v step-up step-down converter transformer

-

original high quality flyback tv transformer bsc25-t1010a

Other Products

-

$5.58 / piece

$5.58 / piece -

$500.00 / set

$500.00 / set -

$63.00 / set

$63.00 / set