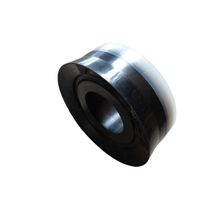

API standard F/PZ/P/NB series drill mud pump parts zirconia ceramic liner for oilfield

-

Supplier: Shandong Great Petroleum Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Mr Edison Young -

Price: $200.00 /set -

Min. Order: 1 set

| Showroom Location: | None; | Supply Ability: | 1000 Set/Sets per Month; |

| Packaging Detail: | standard export package, non-fumigation plywood case; | Packing: | Plywood Box(free-fumigation); |

| Delivery time: | Within 30 Days; | Type: | zirconia ceramic liner; |

| Port: | Qingdao, Tianjin, Shanghai; | Application: | Oil Field; |

| Advantage: | High Performance; | Brand Name: | GP; |

| Market: | Globe; | Color: | as request; |

| Local Service Location: | None; | Applicable Industries: | Energy & Mining; |

| Warranty: | 1 Year,12 MOUNTHS; | Standard: | API; |

| After-sales Service Provided: | Online support; | Condition: | New; |

| Model Number: | F/PZ/P/NB serie; | MOQ: | 3 pcs; |

| Usage: | mud pump; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

API standard F/PZ/P/NB serie drill mud pump parts zirconia ceramic liner for oilfield

We supply mud pump spare parts like mud pump liner( including zirconia ceramic liner and high chrome bi-metal liner), mono-metal Liner, fluid end module, valve and seats, piston, piston rod, pony rod etc. parts for mud pump, we can also customize and machine as your drawing.

High chrome bi-metal liner:

Application:

High chrome bi-metal

liner is used as a kind of mud pump fluid end accessories in the oil drilling industry.

Features:

Our bi-metal liner, API certified, providing wear-resistant outer sleeve and high chrome corrosion-resistant inner sleeve. The high chrome liner has high rigidity of HRC>65 after heat treatment.

Advantages:

The bi-metal liner offers long service life of about 800 hours, which is 2 to 3 times the lifetime of common ones in severe environment.

Zirconia Ceramic liner

* Suitable for deeper oil reservoir,bad drilling geological structure environment,offshore oil and gas development.

*Service time is 5-10 times than bi-metal liners.The using time of liners are up to 6,000 hours.

*The material of ceramic liners is the increased flexible zirconium ceramic.These liners feature wear resistance,high anti-corrosion,high temperature resistance,high pressure,high intensity and high hardness.

*Reduced the freight cost,maintenance cost,labor cost and storage cost of oil drilling.

*Zirconium ceramic liners have better performance than alumina ceramic liners such as more toughness,longer service life,saving water lubrication,reducing wear of piston.

Difference between bi-metal liner and ceramic liner

| Bimetal liner | Ceramic liner |

Material | Outer surface: 45# forging steel Inner sleeve: high chrome alloy

| Outer surface: 45# forgingsteel Inner sleeve: Zirconium ceramic

|

Service cycle | Service life: up to 800 hours

| up to 6,000 hours

|

Price | $50---$250 | $600--$1100 |

We provide the following model and types liners and much more:

BOMCO | F-500 | F-800 | F-1000 | F-1300 | F-1600 | F-1600HL | F-1600L | F-2200HL |

Hong Hua | HHF-500 | HHF-800 | HHF-1300 | HHF-1600 | 3NB-1600F | 5NB-1600 | 5NB-2400 |

|

EMSCO | F-500 | F-800 | F-1000 | F-1300 | F-1600 | FD-1000 | FC-2200 | FB-1300 |

Gardner Denver | PAH | P7 | P8/9 | P10/11 | PXL | PX-11 | PZL | PY-FXD |

National | 7-P-50 | 8-P-80 | 9-P-100 | 10-P-130 | 12-P-160 | 14-P-200 | 14-P-220 | N-1000/1300 |

Oilwell | A-850-PT | A-1100-PT | A-1400-PT | A-1700-PT |

|

|

|

|

TSC | WF-500 | WF-800 | WF-1000 | WF-1300 | WF-1600 | WF-2000 | WF-2200 |

|

IDECO | T-500 | T-800 | T-1000 | T-1300 | T-1600 |

|

|

-

Mud pump accessories hydraulic cylinder liquid end module

-

high flow F800 valve ideco hydraulic api three cylinder bomco price integrated piston mud pump for drilling rig

-

Brand New Stainless steel pipe flange Stainless steel flange bushing

-

API Standard 3NB Series Oilfield Drilling Mud Pump

-

Pulsation dampers and bladder pulsation dampers for API mud pump components

-

8HP Diesel Engine Cement Slurry Pump for BW-160 Drilling Rig

-

High Quality Reciprocating Piston Mud Pump Drilling Mud Pump Drilling Machine Mud Pump

-

F500 mud pump

-

Beyond Supply BW250 BW450 BW800 Piston Rubber Assembly Drilling Mud Pump Spare Parts

-

BW250 powerful small three-cylinder mud pump drilling mud pump for sale

Other Products

-

$75000.00 - $80000.00 / set

$75000.00 - $80000.00 / set -

$30.00 / piece

$30.00 / piece -

$500.00 / set

$500.00 / set -

$20.00 / set

$20.00 / set -

$200.00 / set

$200.00 / set -

$100.00 / set

$100.00 / set -

$482000.00 / set

$482000.00 / set